Toughened glass transportation device with anti-fragmentation structure

A tempered glass and transportation device technology, which is applied in transportation and packaging, multi-axis trolleys, trolley accessories, etc., can solve the problems of non-layered placement structure, poor shock absorption performance, and inadequate treatment of tempered glass protection, reducing the need for The effect of bumping amplitude, convenient loading and unloading, and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

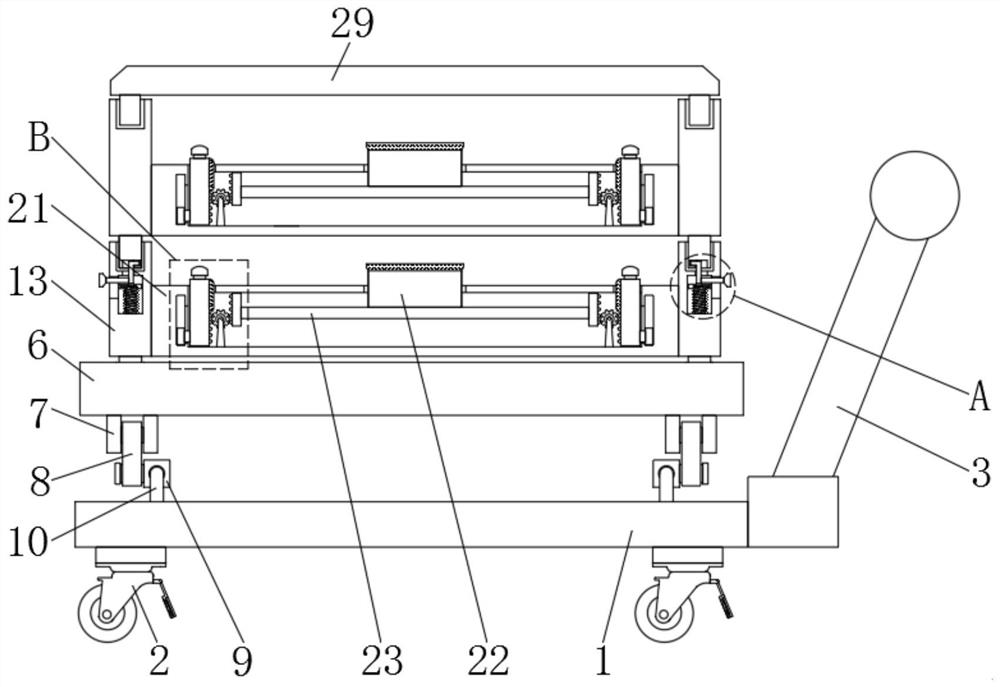

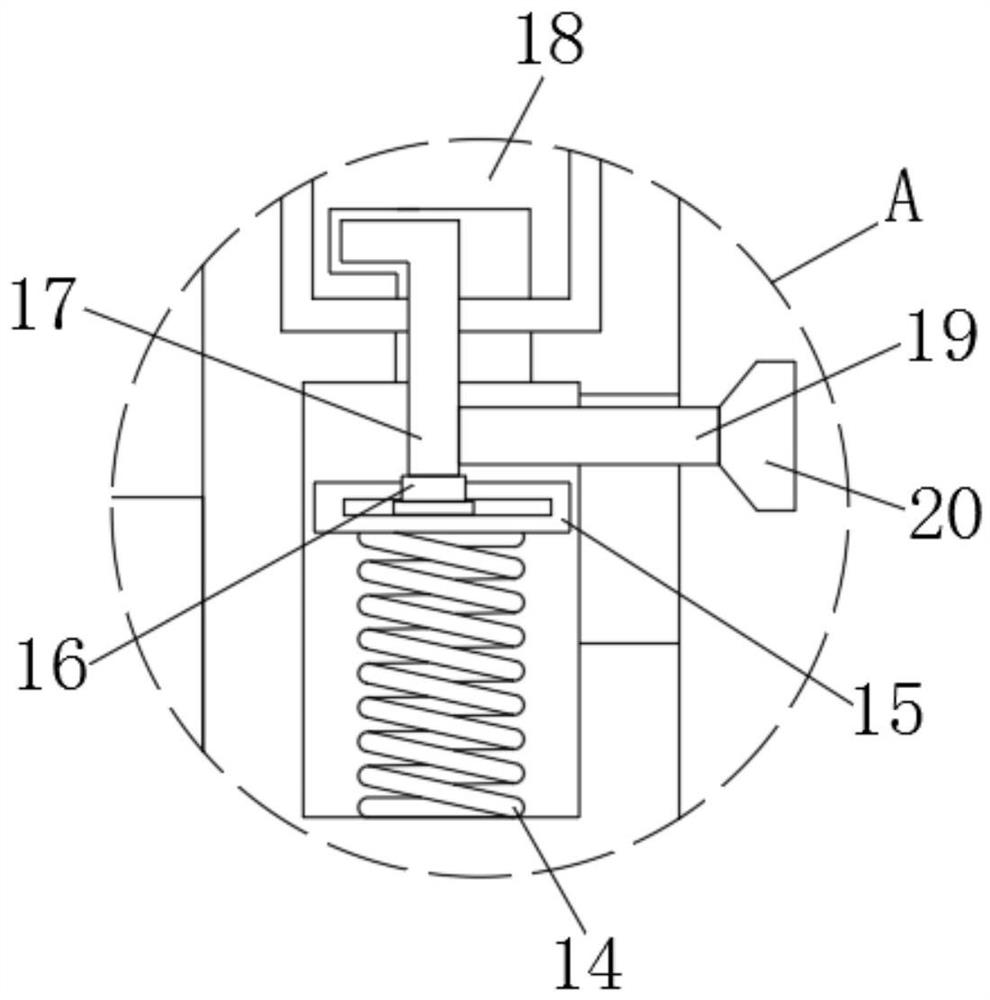

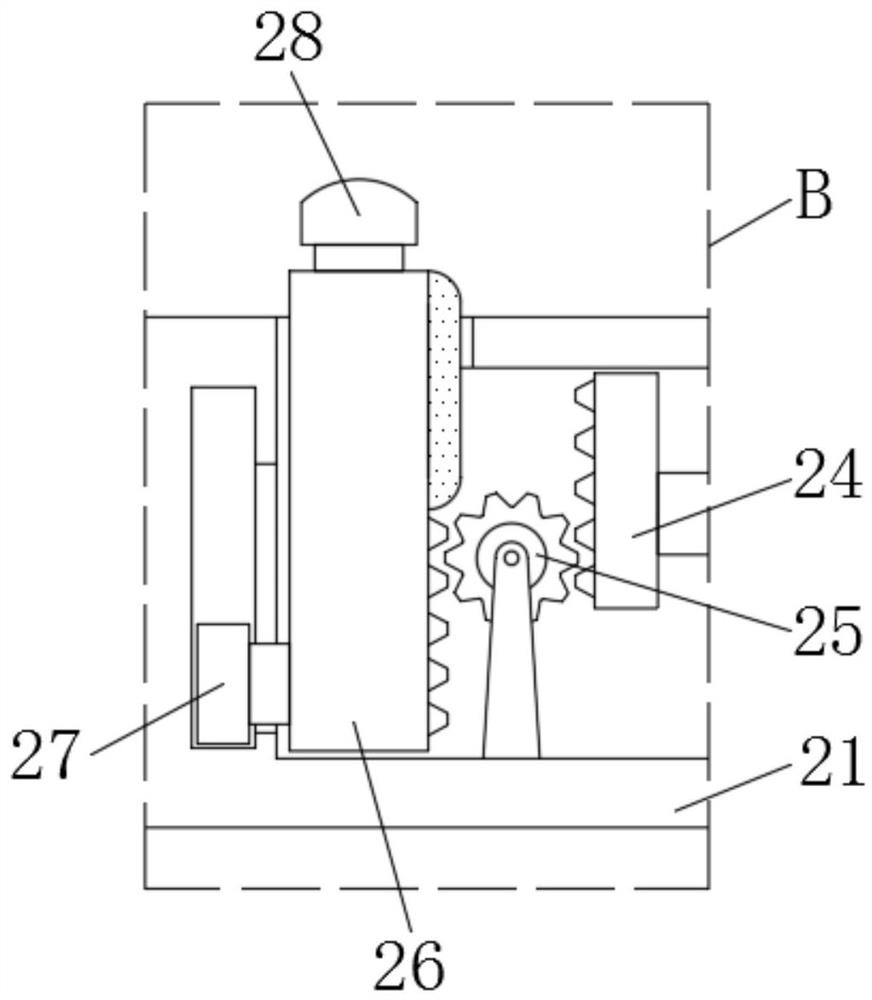

[0030] see Figure 1-7 , an embodiment provided by the present invention: a tempered glass transportation device with an anti-shatter structure, including a base plate 1, universal wheels 2 are fixedly installed around the lower end of the base plate 1, and a drag handle is fixedly installed on the right side of the base plate 1. The rod 3 and the left and right groups of the bottom plate 1 are all fixedly equipped with a cover plate 4, and the upper end of the cover plate 4 is sleeved with a limit plate 5, and the limit plate 5 is movably plugged into the inside of the cover plate 4, where the load-bearing plate can be adjusted. 6 to limit the position, thereby improving the overall stability of the device, the upper end of the limit plate 5 is fixedly installed on the bottom end of the load-bearing plate 6, and the bottom end of the load-bearing plate 6 is fixedly installed with a connecting block 7, and the side of the connecting block 7 is connected to the The rod 8 is hin...

Embodiment 2

[0036] In this example, if Figure 8 As shown, the bottom of the depression bar 23 is connected with the same balance plate 30, the bottom of the placement plate 21 is provided with a first air bag 31 in the cavity, and the side of the splint 26 towards the notch is provided with a second air bag 32, the second air bag 32 is positioned above the upper surface of the placement plate all the time, and the first airbag 31 communicates with the second airbag 32 through the vent pipe 33. During use, when the tempered glass is placed on the placing plate 21, the pressing plate 22 moves downward, on the one hand, the clamping plate 26 is driven up by the pressing bar 23, the second connecting plate 24 and the gear 25, and on the other hand, the pressing plate 22 moves downward. While moving, the balance board 30 moves downwards and presses on the first air bag 31, and the first air bag 31 inflates the second air bag 32 arranged on the splint 26 through the vent pipe 33, and now the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com