Method for automatically constructing prestressed pile

A technology of prestressed piles and prestressed pipe piles, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve the problem that the length of prestressed pipe piles affects construction efficiency, and achieve shortened design length, high bearing capacity, increased Effect of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

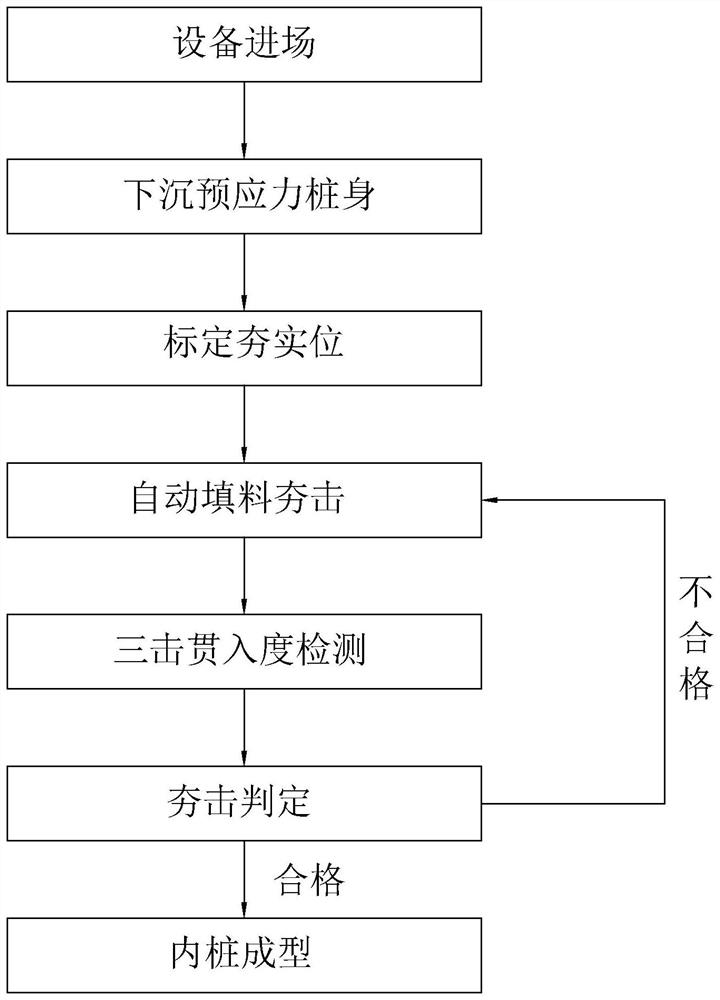

[0037] The embodiment of the present application discloses a method for automatically constructing prestressed piles. refer to figure 1 with figure 2 , the automatic prestressed pile body construction method comprises the following steps:

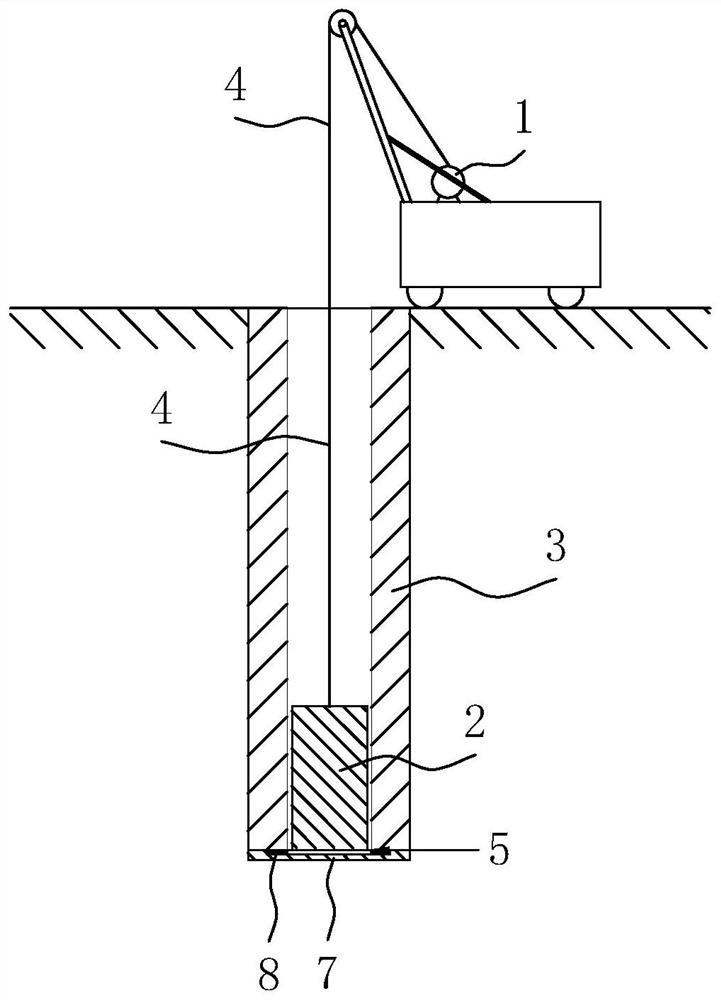

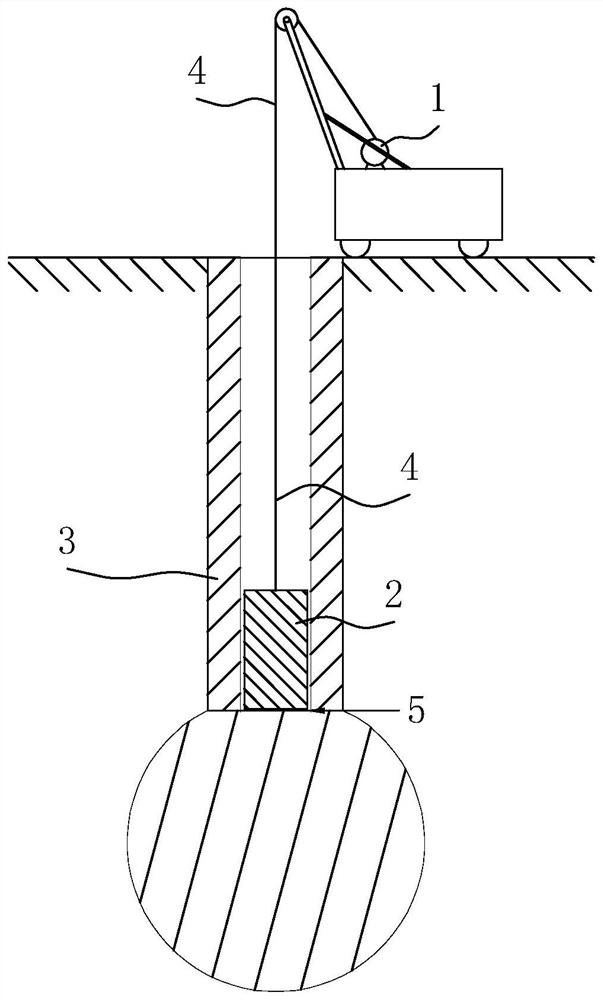

[0038] S1. When the equipment enters the site, prepare the crane, hydraulic hoist 1, rammer 2 and the prestressed pipe pile 3 through the middle at the construction site. The prestressed pipe pile 3 can be a square pipe or a round pipe, depending on the actual construction needs That is, the crane is a crawler crane and multiple sets are prepared for lifting multiple prestressed pipe piles 3; the rammer 2 is adapted to the hollow part of the prestressed pipe pile 3, so that the rammer 2 can pass through the prestressed pipe pile 3; the hydraulic winch 1 winds the lifting rope 4, and installs the rammer 2 on the hook at the end of the lifting rope 4; the above rammer 2, prestressed pipe pile 3, hydraulic winch 1, and crane all Multiple s...

Embodiment 2

[0063] The embodiment of the present application discloses a method for automatically constructing prestressed piles. The difference from Embodiment 1 is that in step S5, after the initial three-strike penetration test, the rammer 2 is replaced with a hollow hammer with a hollow middle part, and the anti-drawing reinforcement is penetrated into the hollow part of the prestressed pipe pile 3, specifically Yes, the anti-pull bar is welded by multiple main steel bars. The end of the main steel bar extending into the lower end of the soil body is integrally bent with a claw steel bar. The angle between the claw steel bar and the main steel bar is 85-95 degrees.

[0064] Before tamping, lift the hollow hammer so that the end of the anti-drawing rib penetrates into the hollow part of the hollow hammer, and repeat steps S4 to S5, and tamp the lower end of the anti-drawing rib into the expanding head through the filler. When pouring concrete in step S7 subsequently, the anti-drawing t...

Embodiment 3

[0066] The embodiment of the present application discloses a method for automatically constructing prestressed piles. refer to Figure 5 , the difference from Embodiment 1 or Embodiment 2 is that the end of the sealing plate 7 away from the prestressed pipe pile 3 is provided with a conical head 10 whose tip deviates from the prestressed pipe pile 3, which can effectively reduce the pressure of the sealing plate 7 along with the prestressed pipe pile 3. When the pile 3 sinks, it can also effectively protect the sealing plate 7, so as to avoid the crushing of the sealing plate 7 caused by gravel during the sinking of the prestressed pipe pile 3, and ensure that the sealing plate 7 is on the prestressed pipe pile 3 The closing effect of the sinking end.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com