Impact force measurement experiment device based on light-gas gun and installation method of impact force measurement experiment device

An experimental device and impact force technology, which is used in measuring devices, force/torque/power measuring instruments, weapon testing, etc., which can solve the problems of difficulty in studying warheads and target plates at the same time, and inability to perform variable-angle impact experiments. Abundant space, convenient installation and disassembly, and high test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

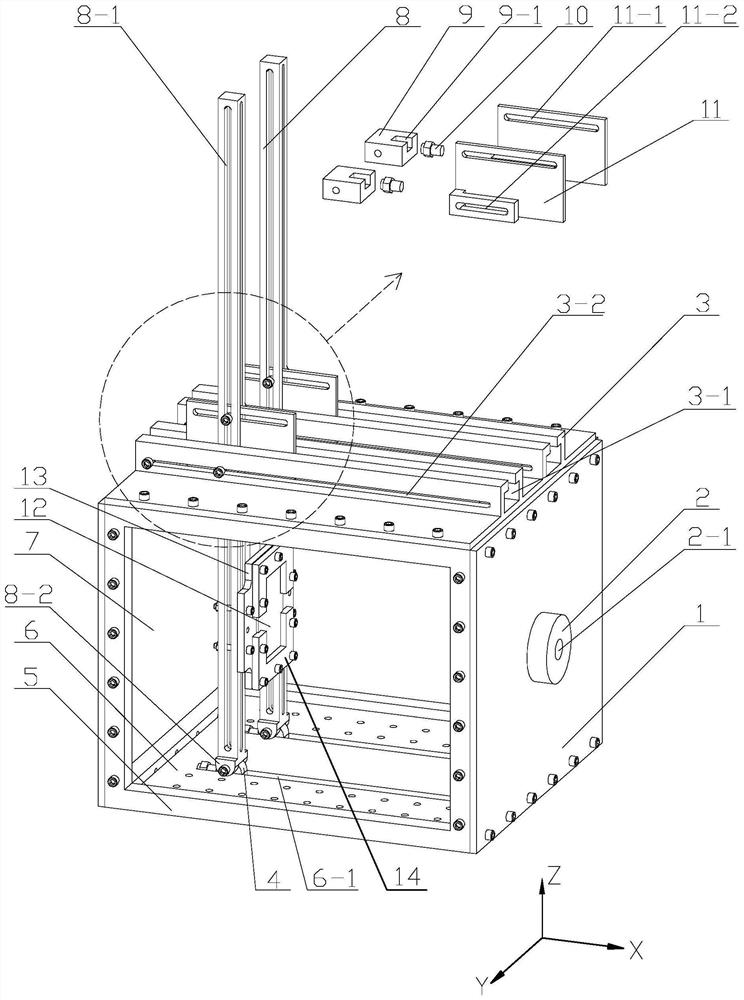

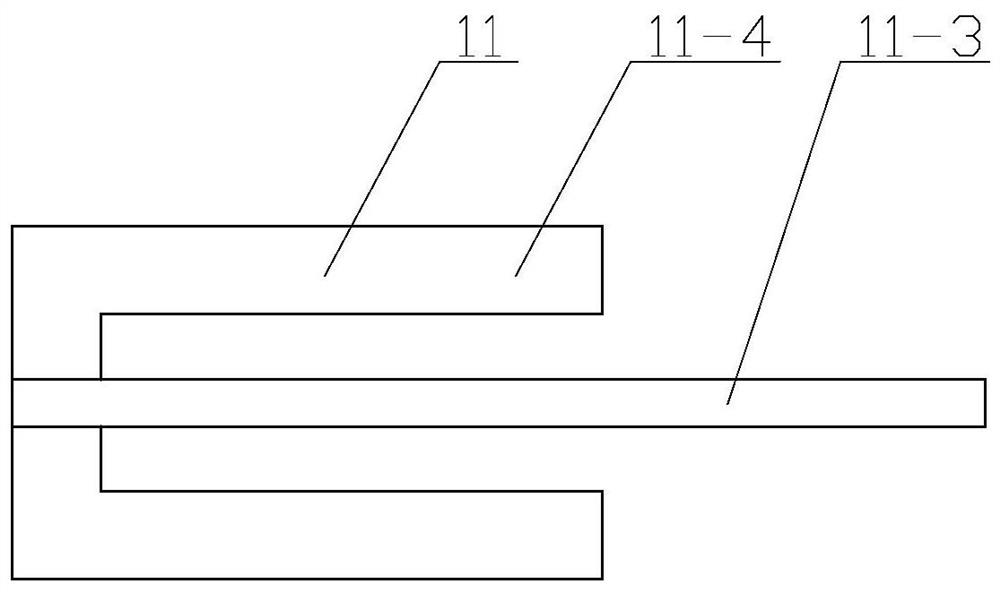

[0025] Specific implementation mode one: as figure 1 , figure 2 As shown, this embodiment discloses an experimental device for measuring impact force based on a light gas gun, including an incident plate 1, a separation flange 2, a chute top plate 3, at least one lower connecting slider 4, and a target cabin load-bearing frame 5 , chute bottom plate 6, three protective plates 7, at least one slide bar with groove 8, at least one sensor top block 9, at least two impact sensors 10, at least one upper connecting slider 11, target plate fixture one 13 and target plate fixture two 14;

[0026] The incident plate 1 (by a plurality of bolts) is fixed on one side of the target cabin bearing frame 5 (the incident plate 1 can prevent the high residual velocity target projectile from bouncing back to damage the equipment and injure the experimenter), and the chute bottom plate 6 ( Through a plurality of bolts) is fixedly connected with the bottom of the target cabin load frame 5, and ...

specific Embodiment approach 2

[0030] Specific implementation mode two: as figure 1 As shown, this embodiment is a further description of specific embodiment one. The target cabin load-bearing frame 5 is a cuboid frame, and each beam of the cuboid frame is made of square steel; the aspect ratio of the cuboid frame is (determines the range of impact angles measured) as (At this time, the adjustable range of the impact angle is between 30° and 90°). The definition of impact angle: the acute angle or right angle between the impact direction vector of the target bomb and the normal vector of the target plate surface, the impact angle is 90°, which is the positive impact.

specific Embodiment approach 3

[0031] Specific implementation mode three: as figure 1 As shown, this embodiment is a further description of specific embodiment 1. The shape of the separation flange 2 is a two-stage stepped shaft (the function of the separation flange 2 is to ensure the smooth incidence of the target bullet and prevent the bullet holder from entering the target. cabin. The outer diameter of the bullet holder is greater than the diameter of the incident hole 2-1 of the separating flange 2), and the small diameter end of the separating flange 2 is fixedly arranged in the central circular hole of the incident plate 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com