Stone thermal-insulation board raw material mixing equipment

A technology of mixing equipment and thermal insulation boards, which is applied in mixers, mixers with rotary stirring devices, and the use of liquid separating agents, can solve problems such as increasing energy consumption and affecting production, and achieve good dust removal effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

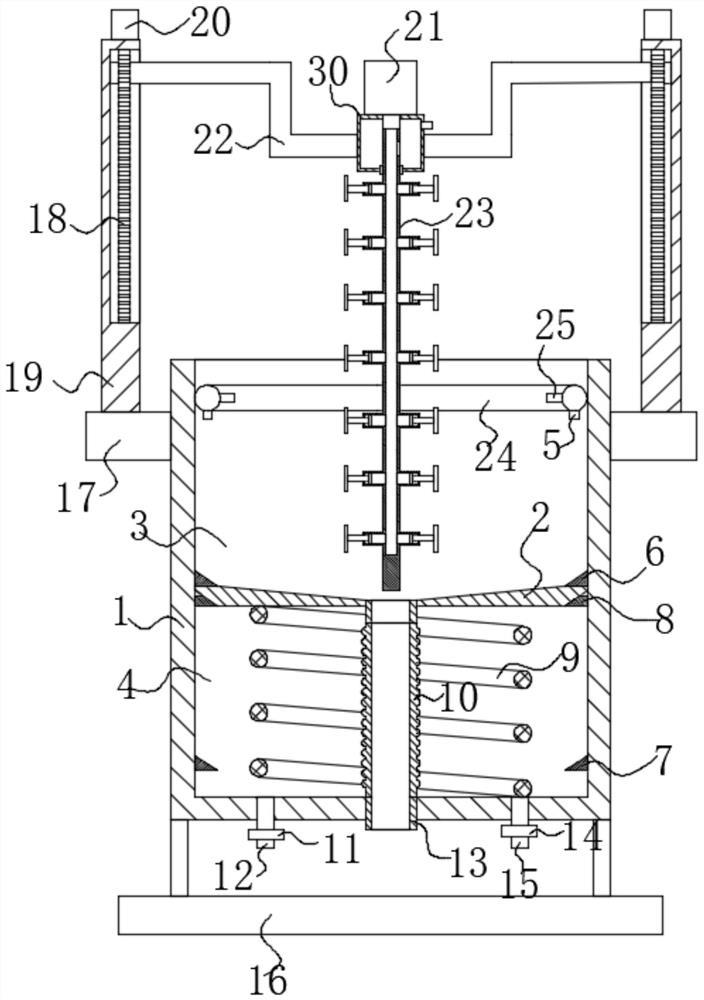

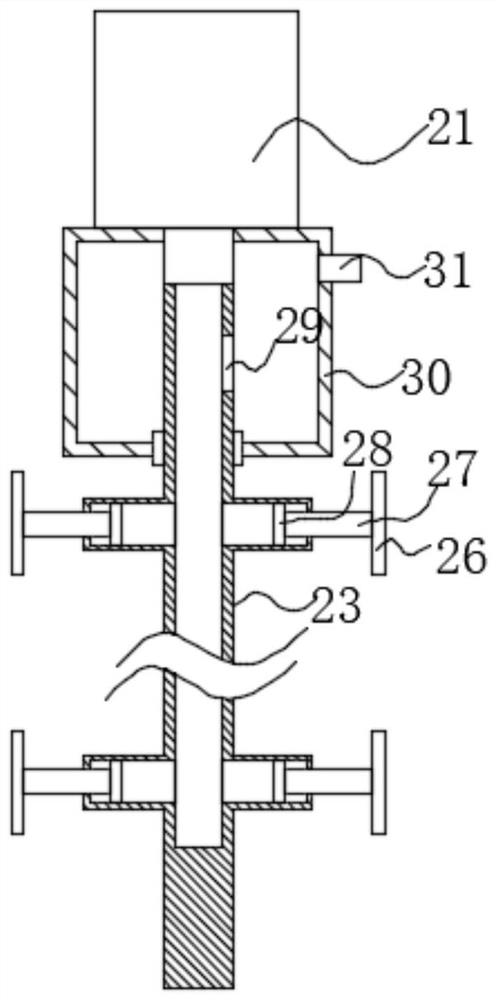

[0019] In order to explain in detail the technical content, structural features, achieved goals and effects of the technical solution, the following will be described in detail in conjunction with specific embodiments and accompanying drawings.

[0020] see figure 1 with 2 , the present embodiment, a stone insulation board raw material mixing equipment, including a tank 1 for mixing, the tank 1 is fixed on the base 16, the top of the tank 1 is open, the tank 1, a partition plate 2 is longitudinally slidably installed, and a sealing ring 8 is installed on the peripheral side of the partition plate 2, so that the partition plate 2 can seal and slide in the tank body 1, and the partition plate 2 separates the tank body 1 into The upper mixing chamber 3 and the lower water chamber 4, the materials to be mixed enter the tank body 1 through the opening at the top, and are deposited on the partition plate 2 to be mixed.

[0021] The water cavity 4 is equipped with a return spring 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com