An energy-saving quick-connect device for construction equipment

A technology for construction equipment and mounting seats, which is applied in the direction of construction and building construction, can solve problems such as troublesome connection methods of connecting rods, environmental pollution on the construction site, and low connection efficiency, so as to save operating time, reduce energy consumption, and improve The effect of connection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

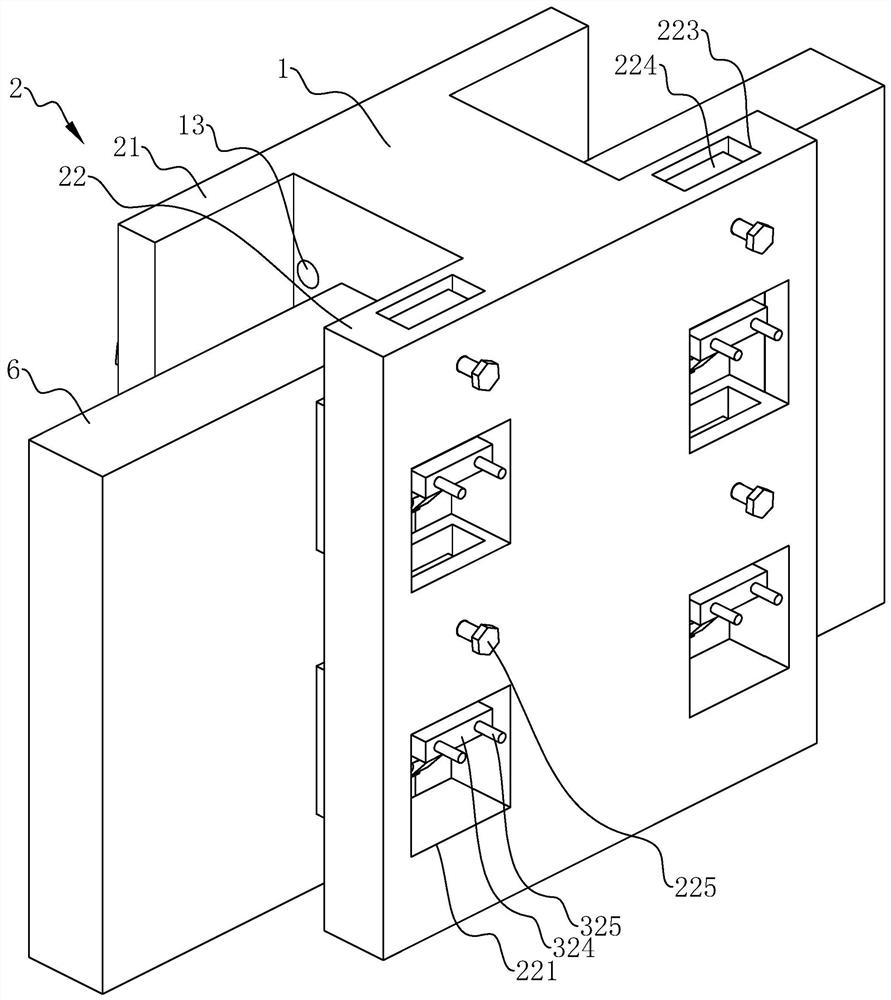

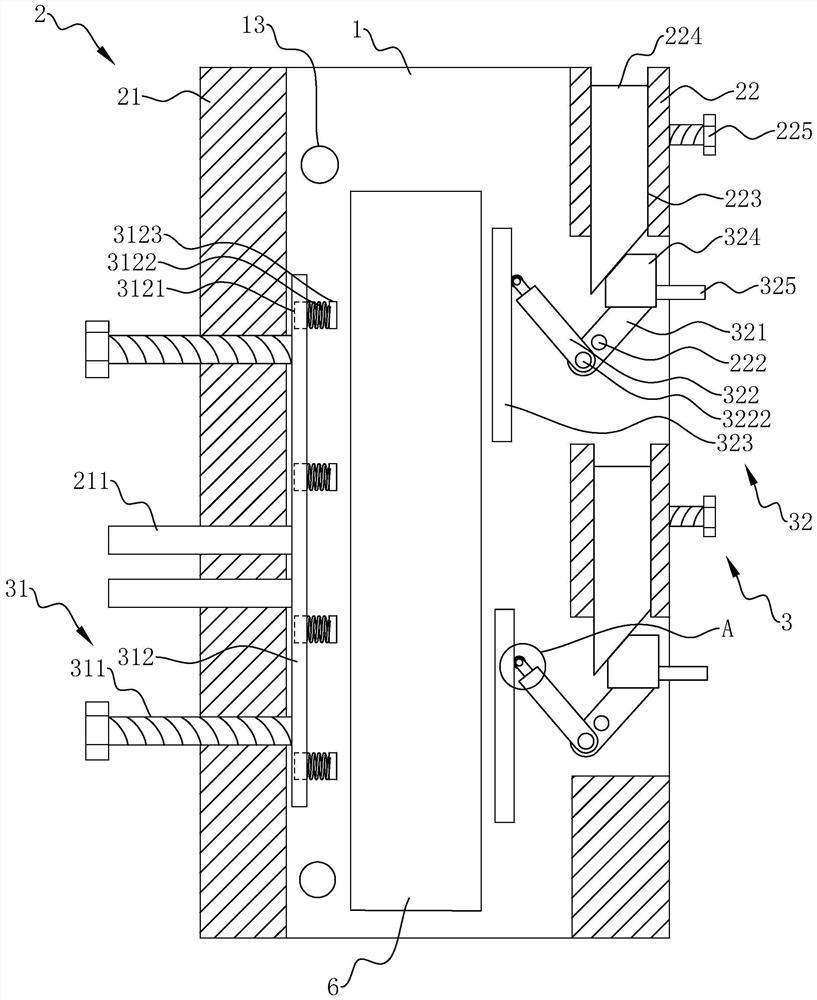

[0038] The embodiment of the present application discloses an energy-saving quick-connect device for construction equipment, referring to figure 1 and figure 2 , which includes a base 1 , a mounting mechanism 2 and a fixing mechanism 3 .

[0039] refer to figure 1 , the base 1 is a cubic structure, which is used for the installation and connection of the installation mechanism 2 here.

[0040] refer to figure 1 and figure 2 , the mounting mechanism 2 includes a first mounting plate 21 and a second mounting plate 22, which are used for the installation of the fixing mechanism 3 here, and a group of mounting mechanisms 2 are respectively provided on opposite sides of the base 1, each group of mounting mechanisms 2 The first mounting plate 21 and the second mounting plate 22 are vertically fixed on the base 1 at intervals.

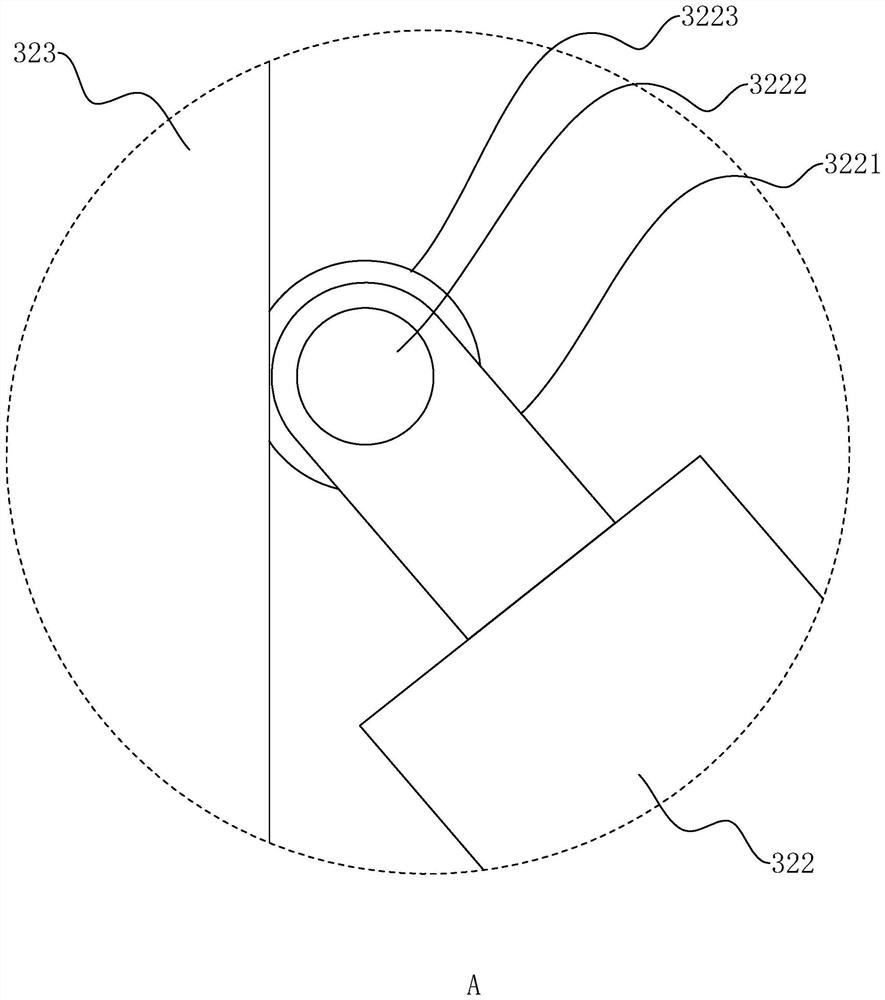

[0041] refer to figure 2 , the fixing mechanism 3 includes an adjusting member 31 arranged on the first mounting plate 21 and a clamping member 32 a...

Embodiment 2

[0056] The difference between this embodiment and Embodiment 1 is that the quick-connect device in this embodiment can change the installation angle of the two prefabricated components 6 in a coplanar state, specifically: the base 1 is moved along the symmetry line of the two sets of installation mechanisms 2 Divided into two parts, the two divided parts are respectively called the first mounting base 11 and the second mounting base 12, two hinges 4 are arranged at the adjacent ends of the two mounting bases, and two hinges 4 in each hinge 4 The sheets are respectively affixed to the side of the two mounting seats away from the mounting mechanism 2, and the first mounting seat 11 and the second mounting seat 12 can be flipped through the hinge 4, thereby changing the position of the two prefabricated components 6 in a coplanar state. The installation angle increases the diversity of the connection and installation of the prefabricated components 6 .

Embodiment 3

[0058] The difference between this embodiment and Embodiment 1 is that the quick-connect device in this embodiment can change the installation angle of the two prefabricated components 6 in a non-coplanar state, specifically: Similarly, the base 1 in this embodiment is also It is divided into two parts along the symmetry line of the two groups of mounting mechanisms 2, and the divided two parts are also called the first mounting base 11 and the second mounting base 12 respectively. A bit slot 111, the step-off slot 111 is perpendicular to the installation mechanism 2 and runs through the first mounting seat 11, a hinged rod 112 is arranged in the center of the step-off slot 111 parallel to the first mounting base 11, and the two ends of the hinged rod 112 are respectively inserted into In the groove walls on both sides of the give way groove 111 and are rotatably connected with the groove walls of the give way groove 111, a rotating rod 5 is fixedly connected on the hinged rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com