Side light-emitting system of thin lamp box

A side lighting and light box technology, applied in the field of side lighting systems, can solve the problem of dust and impurities affecting the lighting effect of thin light boxes, and achieve the effect of easy adjustment and good light display effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

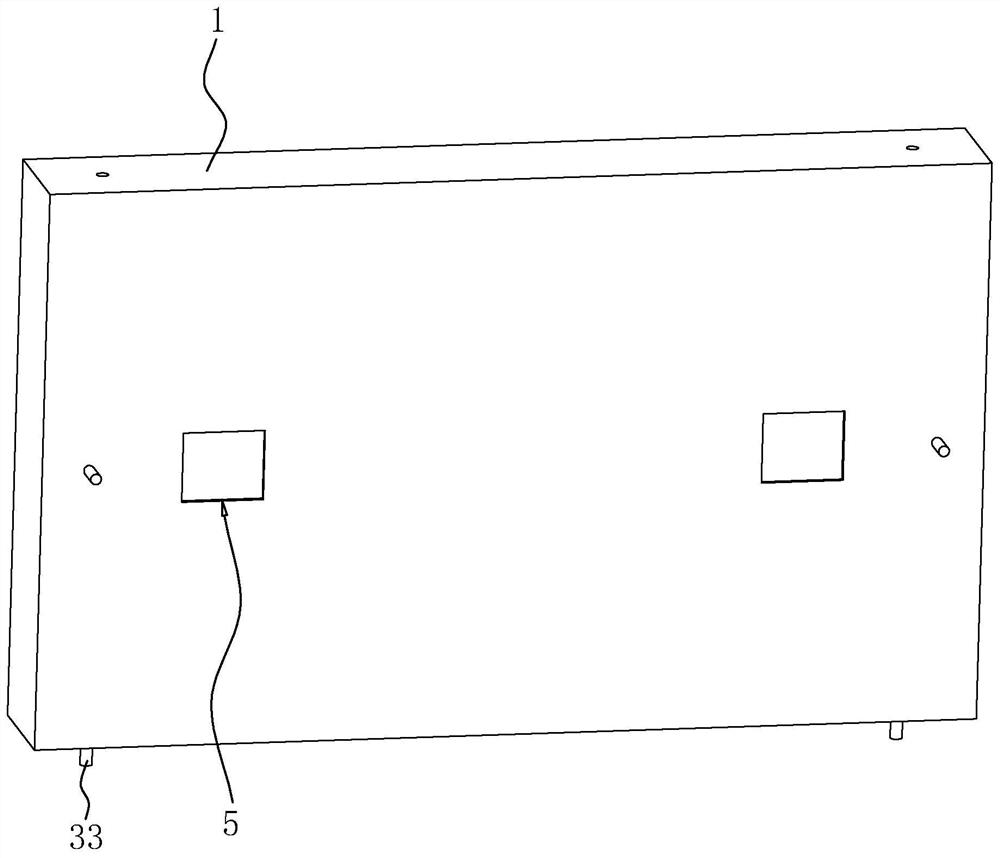

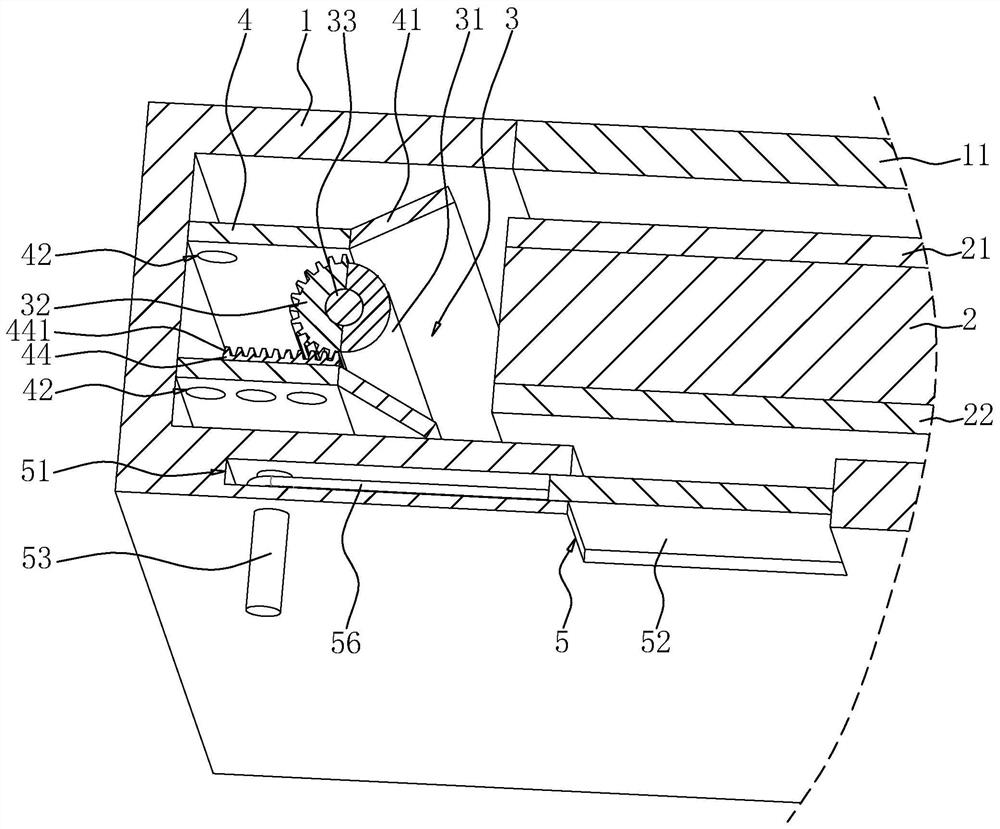

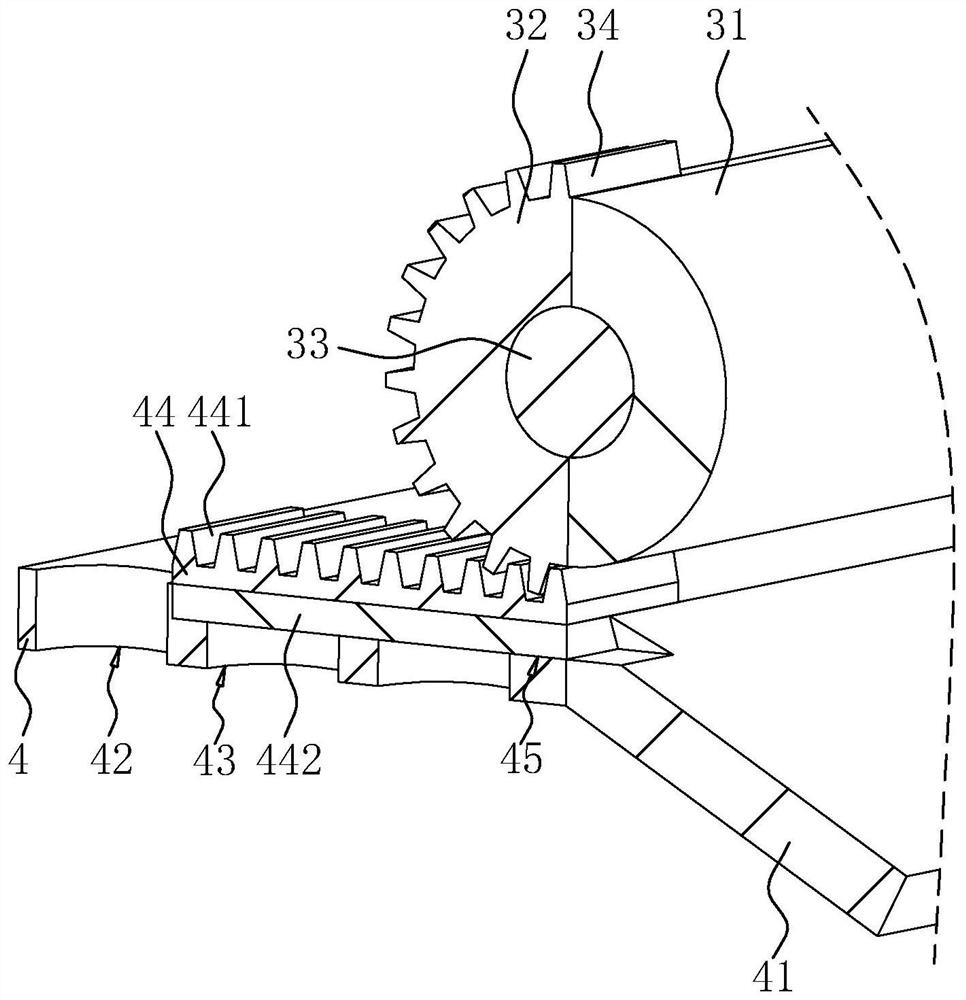

[0035] The embodiment of the present application discloses a side lighting system of a thin light box. refer to figure 1 and figure 2 , the side lighting system includes a frame 1 of hollow structure, and a panel 11 is installed on one side wall of the frame 1 . A light guide plate 2 is arranged inside the frame 1 , an album layer 21 for display is fixedly connected between the light guide plate 2 and the panel 11 , and a reflective film 22 is fixedly connected to the side of the light guide plate 2 away from the album layer 21 . Two light sources 3 are arranged inside the frame 1 , and the two light sources 3 are respectively located on both sides of the light guide plate 2 .

[0036] The heights of the light guide plate 2, album layer 21, and reflective film 22 are the same as those inside the frame 1, the light source 3 is cylindrical, and the height of the light source 3 is equal to the height of the light guide plate 2, and the light source 3 is vertical. Vertical ori...

Embodiment 2

[0051] The embodiment of the present application discloses a side lighting system of a thin light box. refer to Figure 5 , the difference from the first embodiment is that two light sources 3 are arranged between every two baffles 4 . When it is necessary to control the luminous intensity of the thin light box to become weaker, control the two light sources 3 to rotate in opposite directions. The two light sources 3 rotate in opposite directions so that the two light sources 3 are relatively centered to reduce the light irradiated on the light guide plate 2, which is convenient for the thin light box. More uniform light emission.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com