Battery system, micro short circuit fault detection method thereof and battery management system

A battery system and fault detection technology, applied in battery/fuel cell control devices, short-circuit testing, electric vehicles, etc., can solve problems such as inability to detect power battery and heating circuit micro-short-circuit faults, achieve high market application value, reduce Function development cost, simple principle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0040] In this implementation manner, system embodiments and method embodiments are involved, which will be introduced respectively below.

[0041] System embodiment:

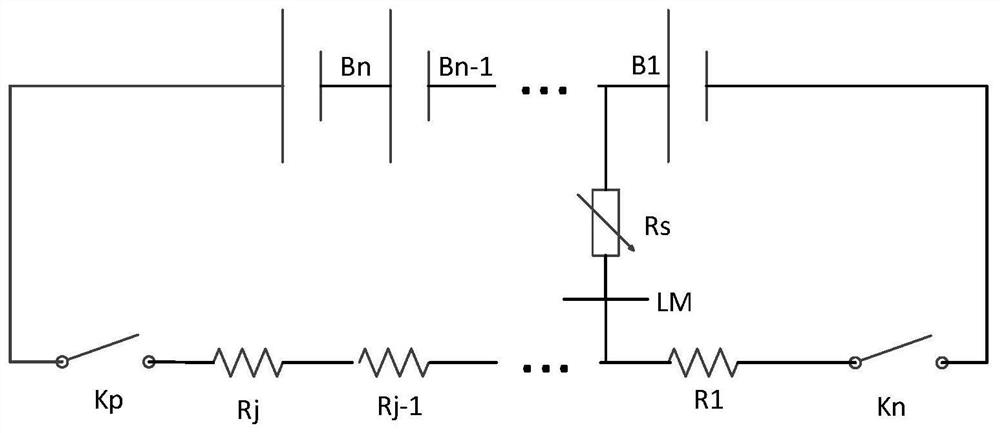

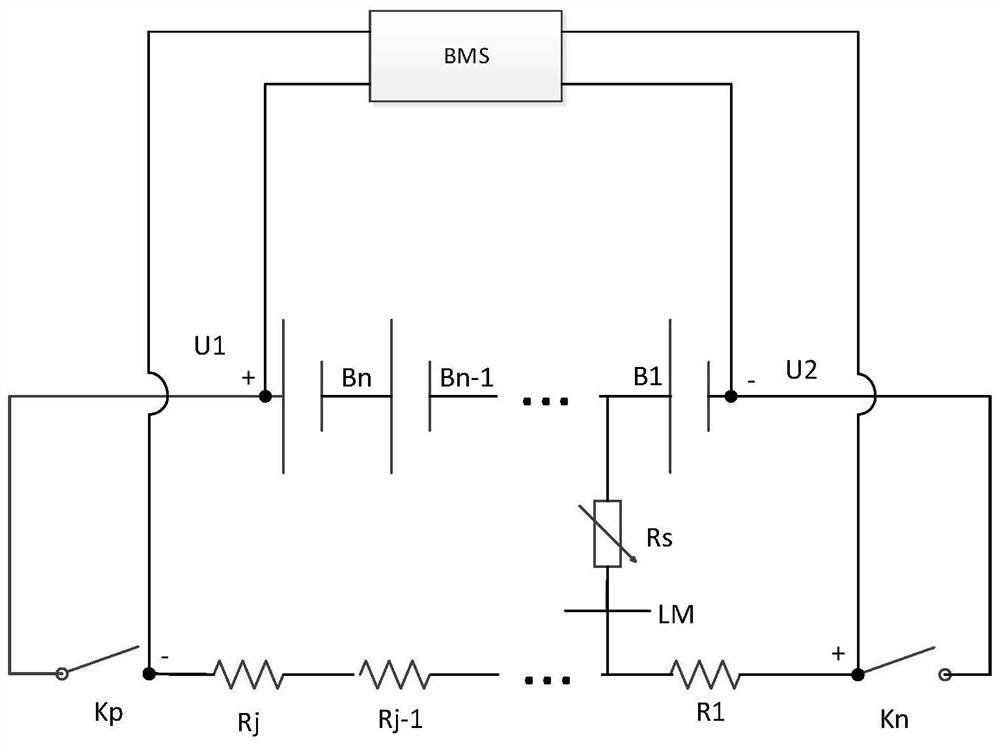

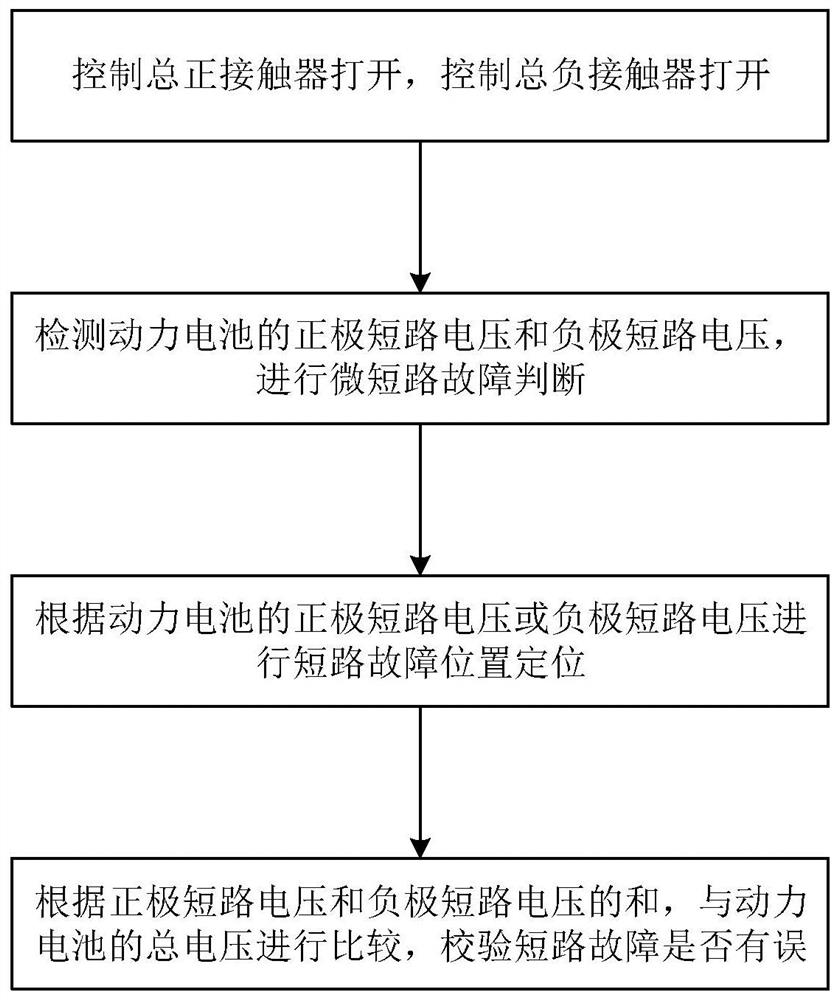

[0042] Such as figure 2 The battery system shown includes a power battery, a heating circuit and a battery management system BMS, wherein the power battery is composed of several single batteries B1,..., Bn-1, Bn, and the heating circuit is sequentially provided with a total positive contactor Kp , heating wires R1,..., Rj-1, Rj and the total negative contactor Kn, the first end of the total positive contactor Kp is connected to the total positive pole of the power battery, and the first end of the total negative contactor Kn is connected to the total negative pole of the power battery , the battery management system BMS includes a memory and a processor, as well as a computer program stored on the memory and run on the processor, wherein the processor respectively detects the total positive pole and the tota...

Embodiment approach 2

[0097] In this implementation manner, system embodiments and method embodiments are involved, which will be introduced respectively below.

[0098] System embodiment:

[0099] Such as Figure 5 As shown, this embodiment proposes a battery system. Unlike the battery system in the system embodiment of Embodiment 1, the processor of the battery management system BMS in the battery system of this embodiment does not need to detect the total negative contact in the connection thermal circuit. The processor detects the second end of the total positive contactor Kp connected to the power battery and the second end of the total positive contactor Kp in the heating circuit respectively, and the processor also controls the connection between the total positive contactor Kp and the total negative contactor. Contactor Kn.

[0100] In this embodiment, the processor of the battery management system BMS is coupled to the memory, and the processor implements the micro-short circuit fault de...

Embodiment approach 3

[0116] In this implementation manner, system embodiments and method embodiments are involved, which will be introduced respectively below.

[0117] System embodiment:

[0118] Such as Figure 6 As shown, this embodiment proposes a battery system. Unlike the battery system in the system embodiment of Embodiment 1, the processor of the battery management system BMS in the battery system of this embodiment does not need to detect the total positive contact in the connection thermal circuit. The processor detects the second end of the total positive pole and the total negative pole connected to the power battery, and the second end of the total negative contactor Kn in the heating circuit, and the processor also controls the connection between the total positive contactor Kp and the total negative pole. Contactor Kn.

[0119] In this embodiment, the processor of the battery management system BMS is coupled to the memory, and the processor implements the micro-short circuit fault...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com