Guide profile and conveyor system

A technology for conveying systems and profiles, applied in the field of conveying systems, can solve problems such as troublesome replacement of sliding slats, and achieve the effect of simplifying installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

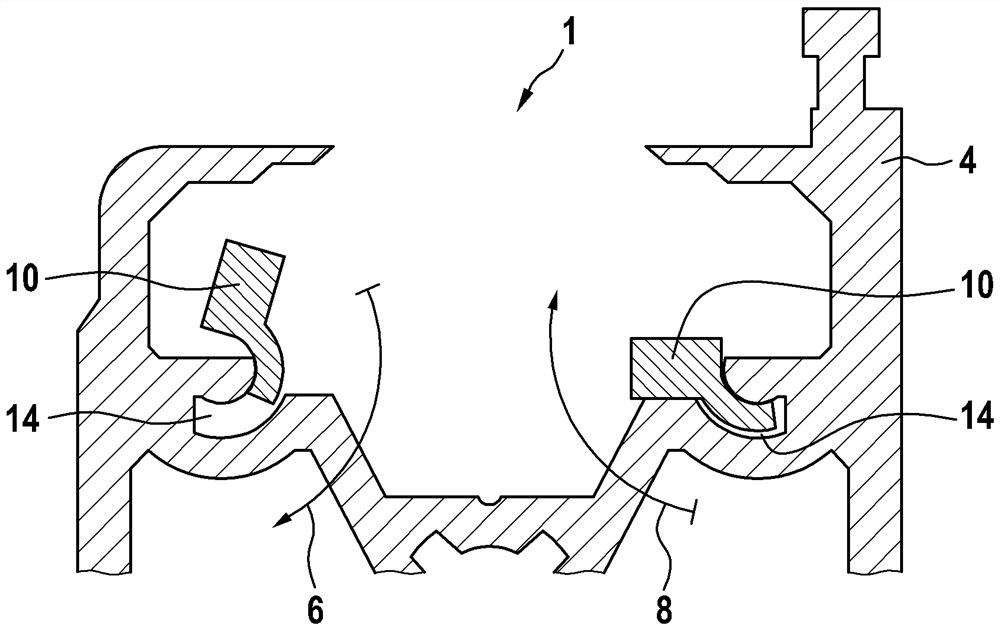

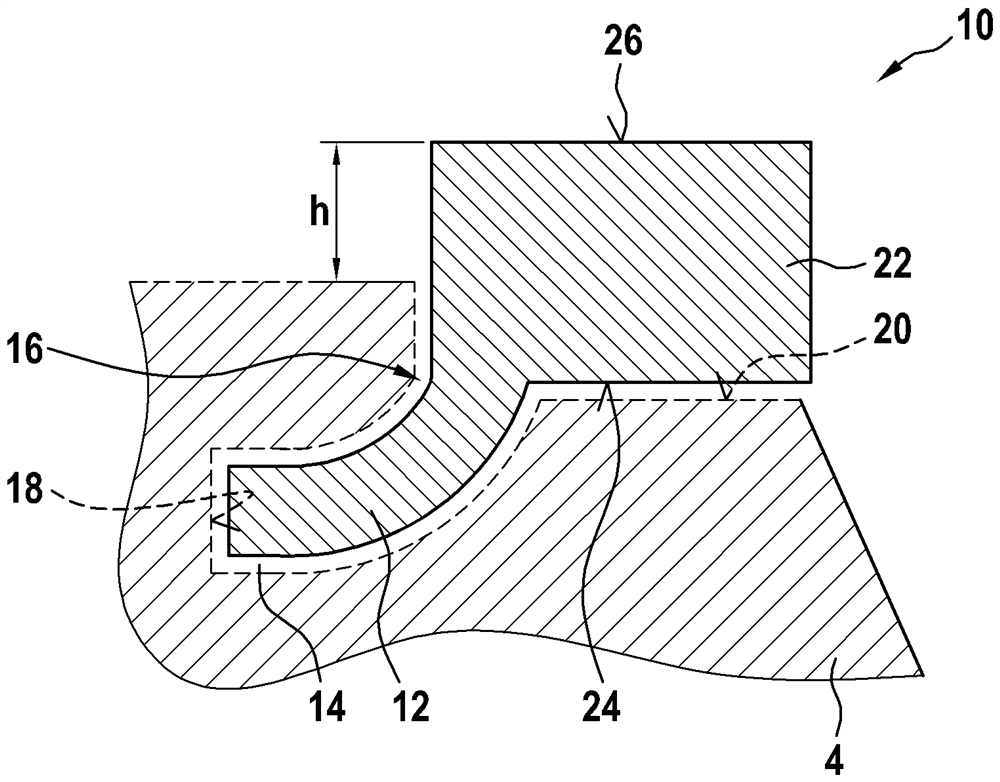

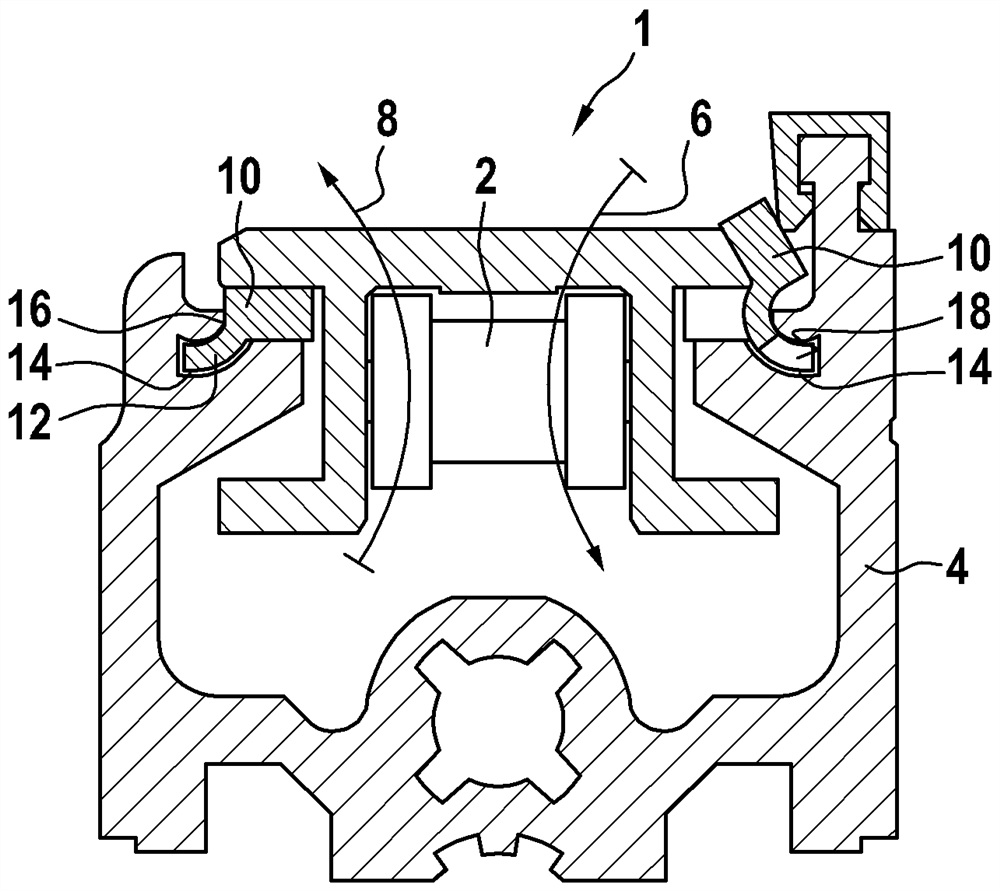

[0050] exist figure 1 shows part of a conveyor system 1 with a flat chain 2 , which is guided by means of a profile body 4 . The conveying direction of the conveying system 1 runs perpendicularly to the plane of the illustration in the present exemplary embodiment. The flat chain 2 is guided in a manner known per se along a sliding strip 10 which is held exchangeably on the profile body 4 . In order to illustrate the insertion and removal directions 6 , 8 of the sliding strips 10 , the right-hand sliding strip 10 is shown in the inserted position in the illustration. “Installation position” means the first installation step in which the sliding strip 10 is placed with the end section of a joint leg 12 on the recess 14 . The sliding slats 10 in their final position are shown on both sides.

[0051] The sliding strip 10 is equipped with a curved joint leg 12 at the corner area 16 , which sinks into the recess 14 of the profile body 4 until the end part of the joint leg 12 abu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com