A spraying device with anti-solidification function for textile coloring

A spray device and anti-coagulation technology, applied in the field of textile processing, can solve the problems of insufficient environmental protection, affecting the circulation of the coloring solution, and high power consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

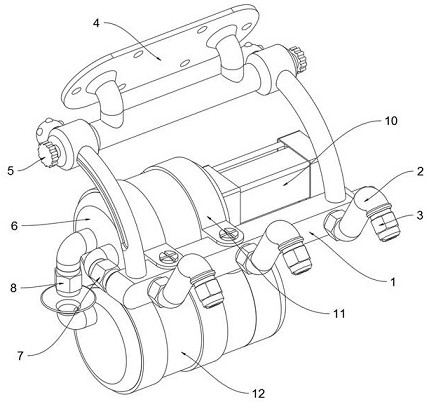

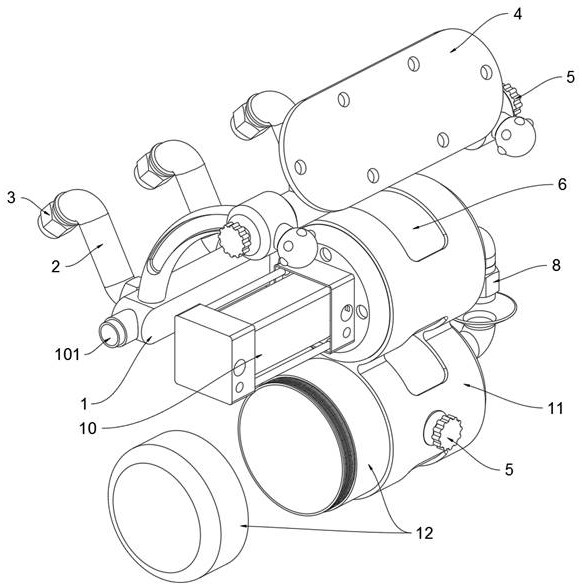

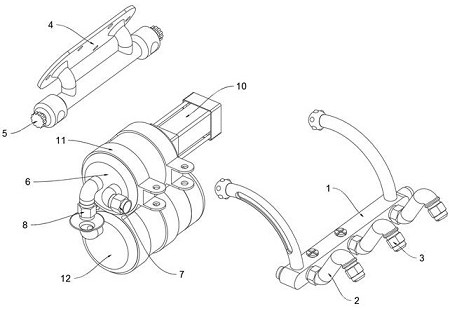

[0040] as attached figure 1 to attach Figure 7 Shown:

[0041] The present invention provides a spraying device with an anti-solidification function for textile coloring, which includes a main pipe 1, a support seat 4, a suction barrel 6 and a suction plate 9;

[0042] The right end of the main pipe 1 is provided with a liquid inlet 101, and the liquid inlet 101 is connected with the coloring liquid supply pipeline, and the rear side of the left end of the main pipe 1 is provided with a liquid outlet 102; the left and right ends of the support seat 4 are respectively connected with manual bolts 5 , and the main pipe 1 is connected to the bottom of the support seat 4, the top left and right ends of the main pipe 1 are respectively provided with adjusting sliding rods 103, the left and right ends of the bottom of the supporting seat 4 are respectively provided with guiding sliding holes 401, and the adjusting sliding rods 103 are slidably connected to the guiding sliding holes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com