Connection structure of prefabricated sheet piles and construction method thereof

A technology for connecting structures and prefabricated slabs, which is applied in foundation structure engineering, sheet pile walls, excavation, etc., can solve the problems of prolonging the construction period and long time consumption, and achieve the effects of enhancing stability, connecting firmly, and saving construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The following is attached Figure 1-6 The present invention is described in further detail.

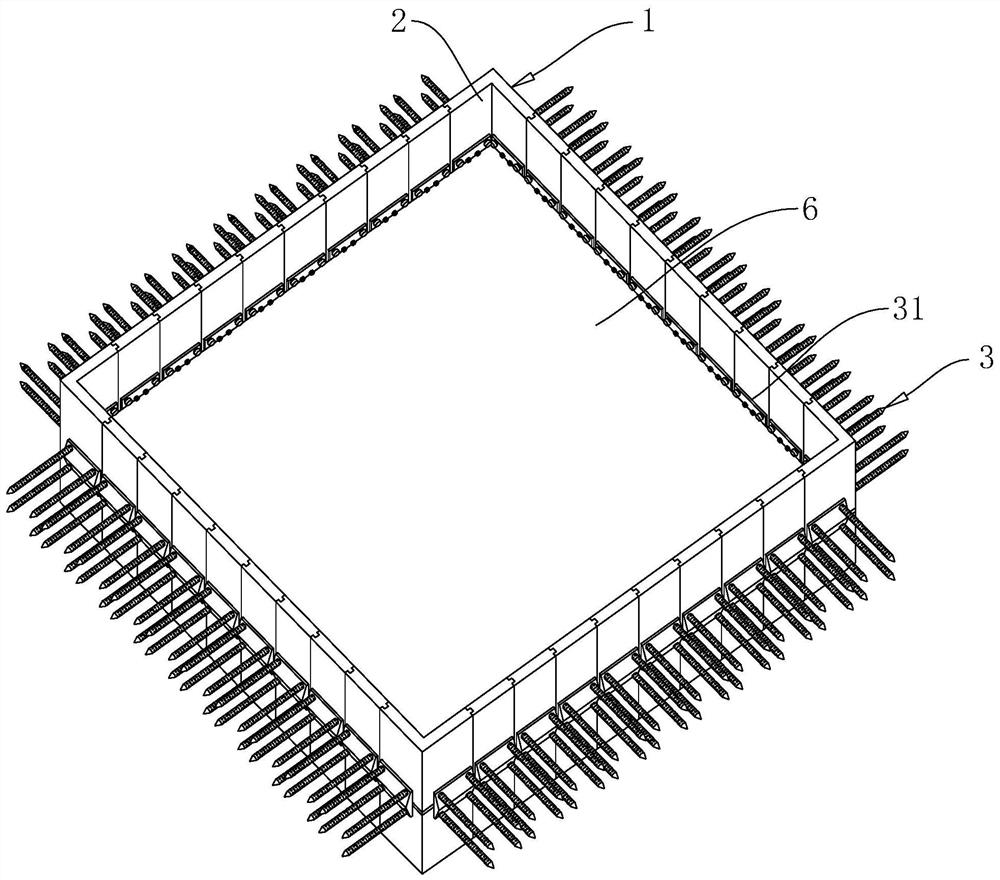

[0043] A connection structure of prefabricated sheet piles and its construction method disclosed in the embodiment of the application, such as figure 1 As shown, it includes several sheet pile units, and several sheet pile units are sequentially spliced along the circumference of the foundation pit to form the foundation pit enclosure 1. The plate body 2 at the corner of the foundation pit enclosure 1 is a right-angle plate, and the foundation pit enclosure 1 is surrounded by a cuboid , the pile foundation unit includes two boards 2 vertically connected up and down and a connection assembly 3 for connecting the two boards 2 .

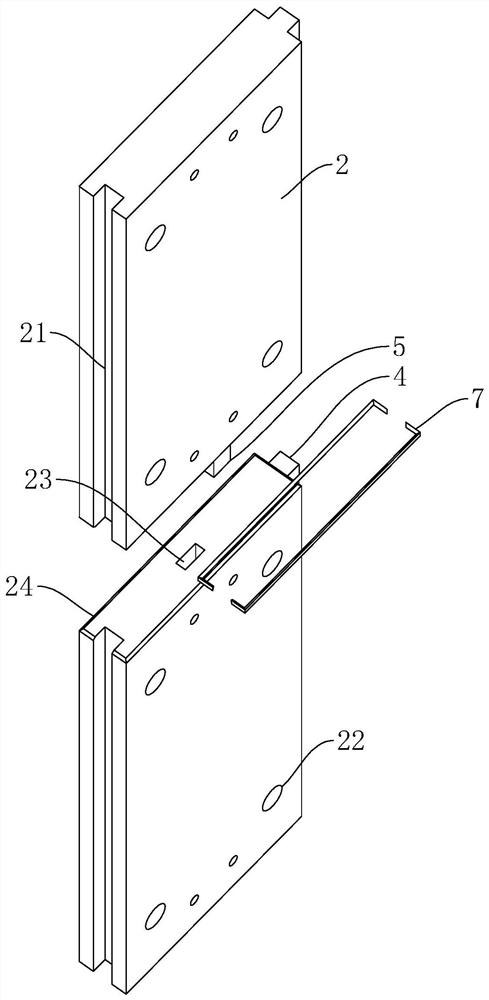

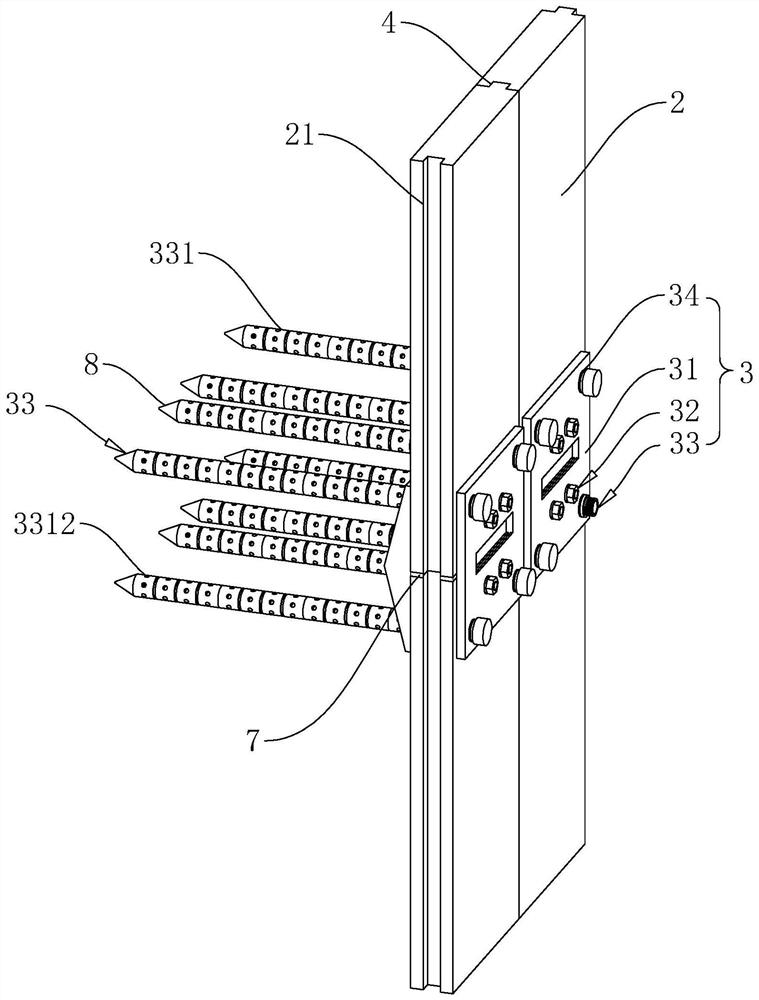

[0044] Such as figure 2 As shown, an insert block 4 is integrally formed along the vertical direction in the middle part of one end face of the plate body 2, and the middle part of the end face of the plate body 2 relative to the insert block 4 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com