Welding-free net rack node reinforcing structure

A structure strengthening and welding-free technology, which is applied in special structures, building components, building structures, etc., can solve problems such as the difficulty in reinforcement of bolt ball joints, and achieve the effects of increasing rigidity, ensuring safety, and facilitating construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

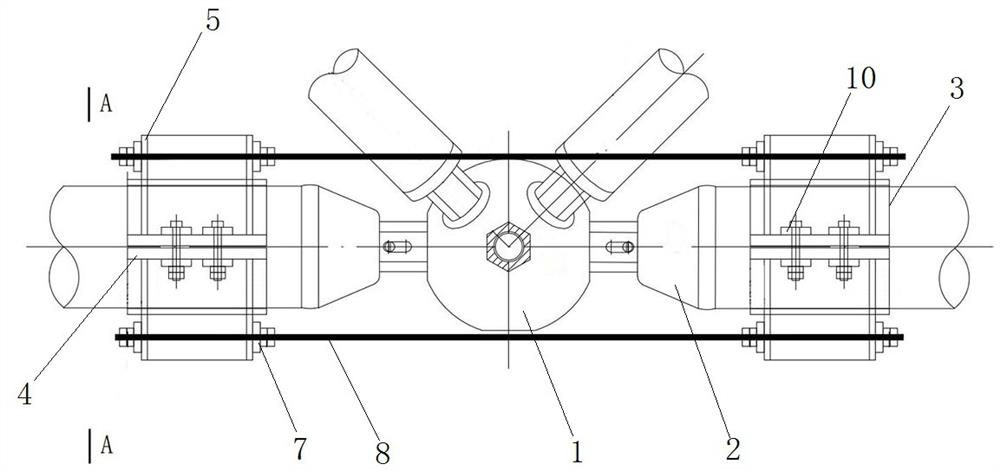

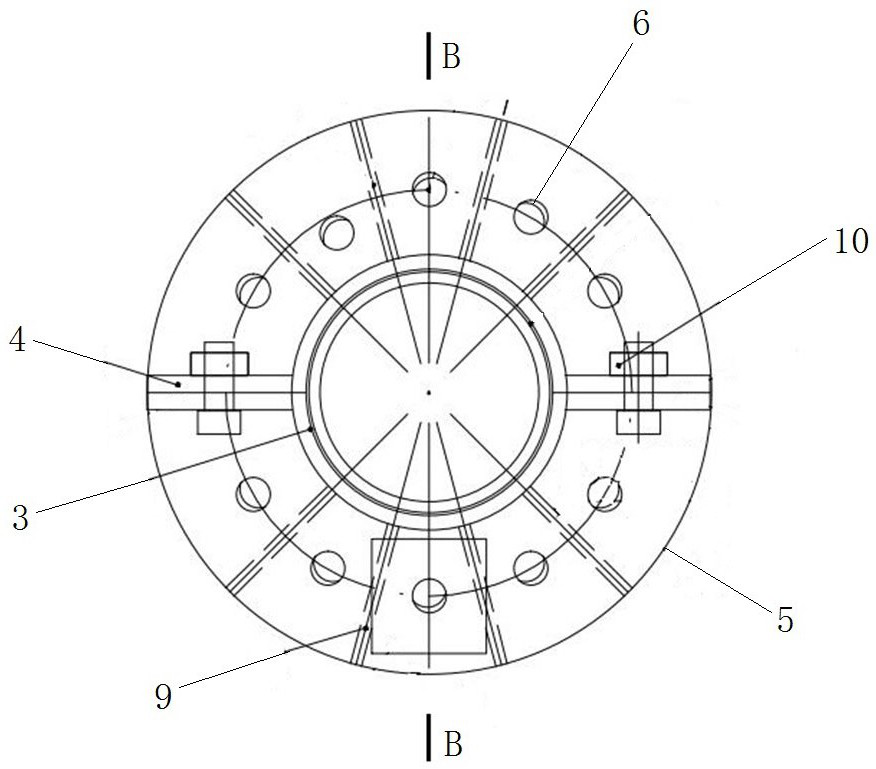

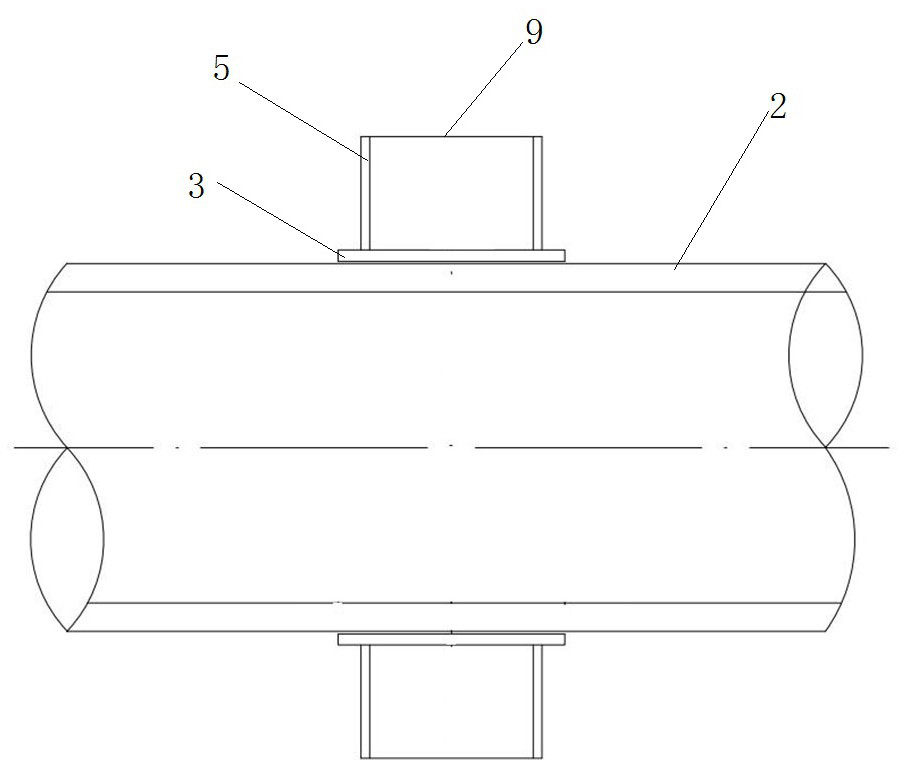

[0031] like figure 1 As shown, the weld-free network frame node reinforcement structure includes a pair of intermediate reinforcement hoops and a pair of tension components. There are two pairs of reinforcement hoops in the middle, which are correspondingly fastened on the two grid tie rods 2 at the radial sides of the same middle bolt ball 1 and at an angle of 180°. like figure 2 , image 3 and Figure 4 As shown, the middle reinforcement hoop pair includes two hoops with the same structure, and each hoop includes a semi-arc hoop plate 3, a flange 4 welded to the radial ends of the semi-arc hoop plate 3 and welded joints. Flange connection plates 5 on both axial sides of the semi-arc hoop plate 3 . Wherein, the inner diameter of the semi-arc hoop 3 is the same as the radius of the grid tie rod 2 to be tightened, the wing 4 is parallel to the axis of the semi-arc hoop 3, and each wing 4 is provided with two spacers. Arranged bolting holes. The flange connecting plate 5 ...

Embodiment 2

[0037] like Figure 5 , Figure 6 and Figure 7 As shown, the welding-free network frame node reinforcement structure of this embodiment includes a pair of end reinforcement hoops and a reinforcement steel wire rope 18 to reinforce the connection node with the end bolt ball 11 of the steel network structure. There is a pair of end reinforcing hoops, which are used to tighten on the grid tie rods 12 connected with the end bolt balls 11, including two hoops with the same structure, and each hoop includes a semi-arc hoop plate 13 , the wing plates 14 connected to the radial ends of the semi-arc hoop 13 and the flange connecting plates 15 welded to the axial sides of the semi-arc hoop 13, the semi-arc hoop 13, the wing 14 and the flange The structure of the flange connecting plate 15 and the connection relationship between the three are the same as the structure of the semi-arc hoop plate 3, the wing plate 4 and the flange connection plate 5 in the above-mentioned embodiment 1 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com