Abnormal data detection and restoration method and system based on while-drilling electric imaging image

An abnormal data detection and imaging data technology, which is applied in the directions of surveying, earthwork drilling, character and pattern recognition, etc., can solve the problems affecting the image clarity and image quality of EWD imaging, and achieve the elimination of abnormal data and restore the original Image information, the effect of removing background differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

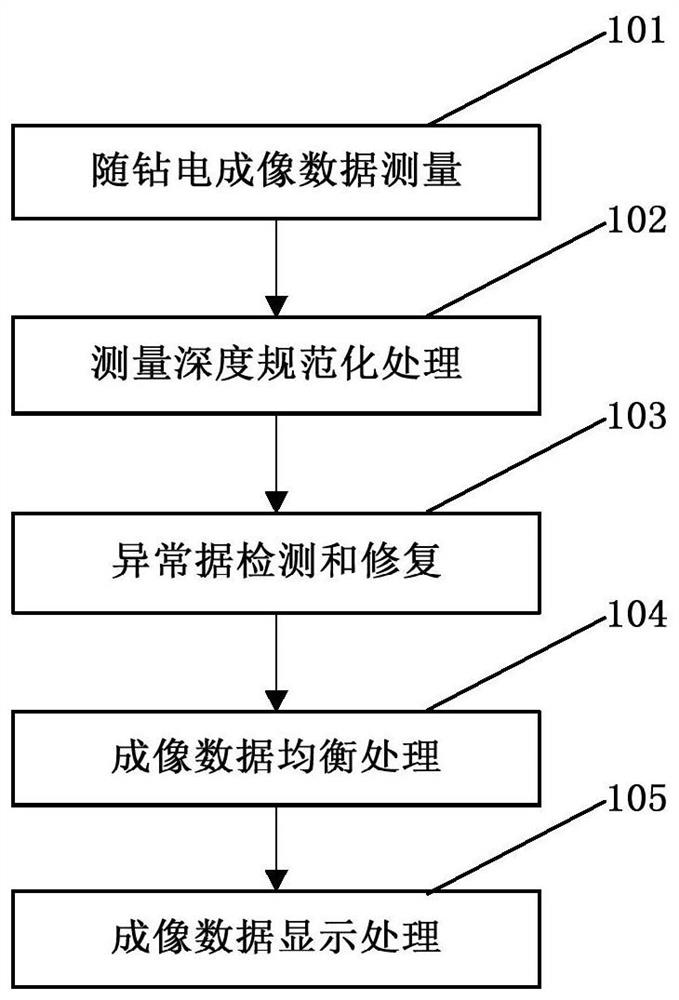

[0031] figure 1 A schematic diagram showing the processing flow of the abnormal data detection and repair method based on electrical imaging while drilling images according to the embodiment of the present invention, refer to the following figure 1 to illustrate the steps of this method.

[0032] In step S101, measurement of electrical imaging while drilling data is performed.

[0033] Specifically, electrical imaging while drilling data are obtained by using electrical imaging while drilling.

[0034] It should be noted that the electrical imaging measurement data while drilling has the following characteristics: the instrument is rotated during the actual measurement process, and it measures data in multiple directions in the circumferential direction. The data obtained during the whole measurement process is a two-dimensional array data. Different columns represent the measured values of different azimuths, and different rows represent the measured values of different d...

Embodiment 2

[0072] Figure 5 A schematic diagram showing the functional structure of the system for detecting and repairing abnormal data based on electro-imaging images while drilling according to Embodiment 2 of the present invention. Refer below Figure 5 The composition and function of the system 60 will be described.

[0073] Such as Figure 5 As shown, the system 60 includes: a measurement depth normalization processing module 61 , an abnormal data detection and repair module 62 , an imaging data equalization processing module 63 and an imaging data display processing module 64 . The measurement depth normalization processing module 61, which performs the screening of the depth data and the depth resampling of the measurement data for the obtained electrical imaging measurement data while drilling; the abnormal data detection and repair module 62, which performs the electrical imaging while drilling The imaging measurement data is used to detect and repair abnormal data; the imag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com