X-RAY detection equipment capable of realizing microscopic CT (Computed Tomography)

A technology of detection equipment and modules, applied in the field of x-ray detection, can solve the problems of difficult to determine the specific location of defects, inconvenient use, low detection efficiency, etc., and achieve the effects of compact structure, avoiding radiation leakage, and low detection cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

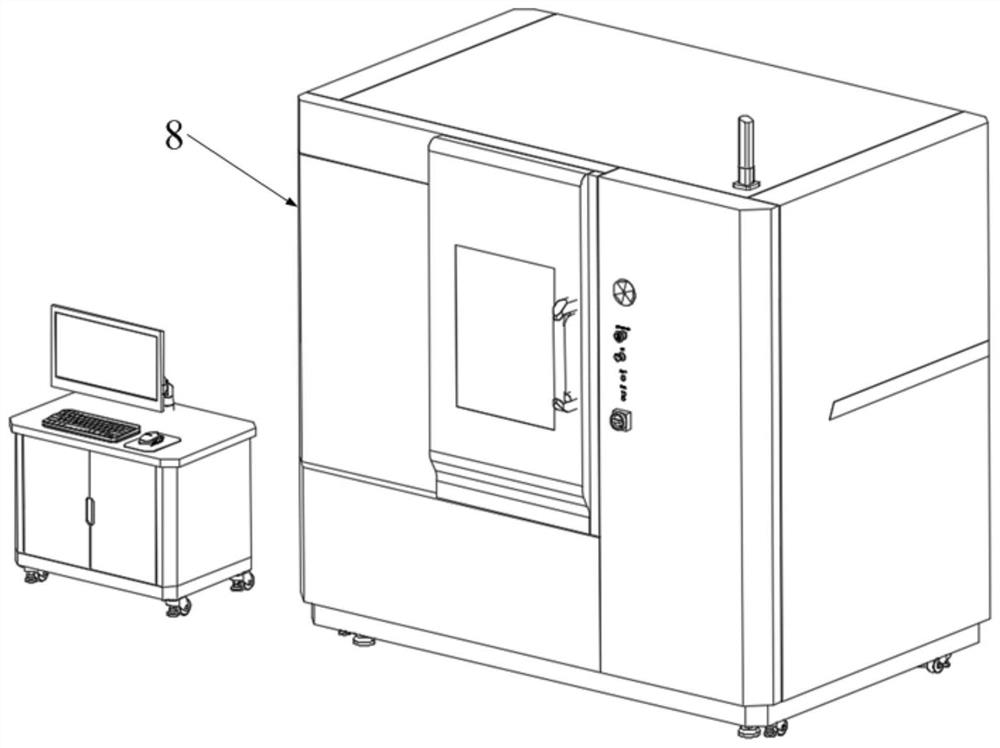

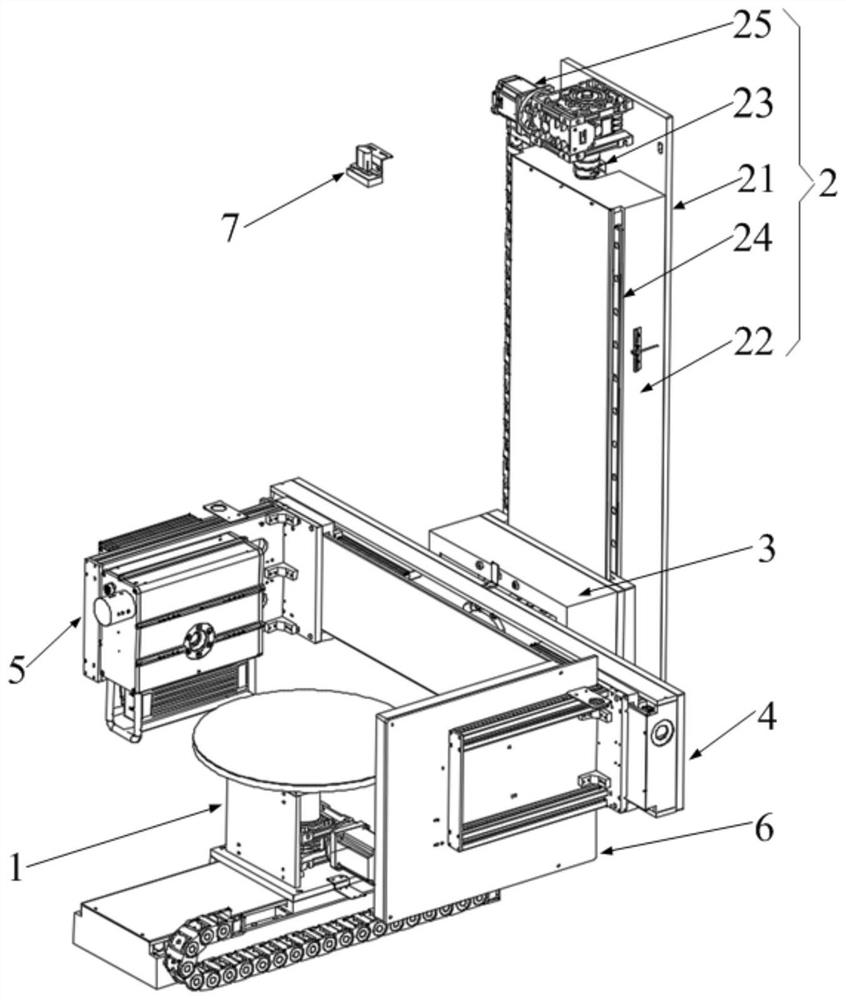

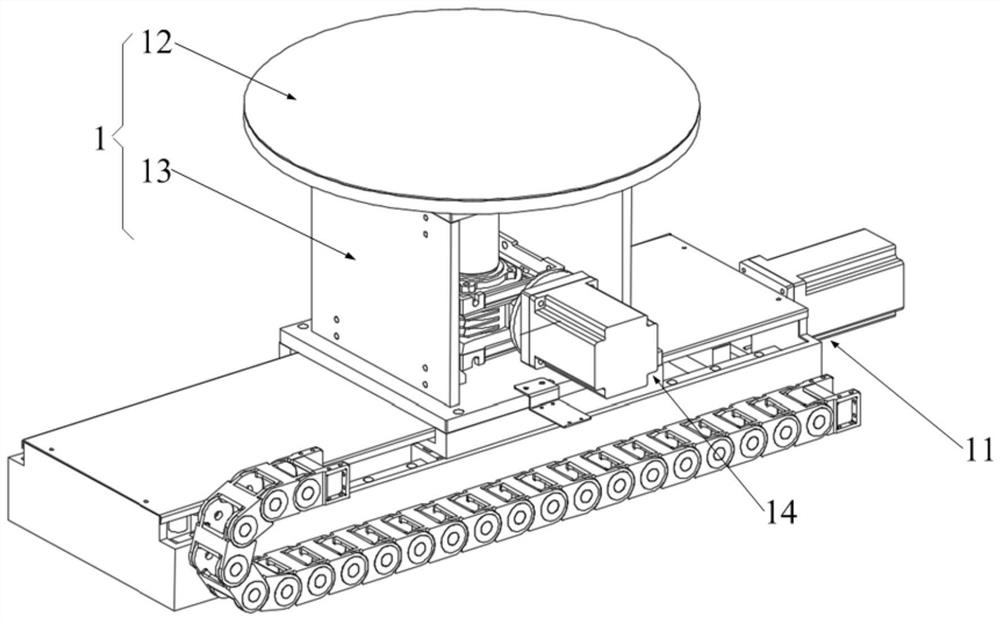

[0037] refer to Figures 1 to 4 As shown, the present invention provides an X-RAY detection device capable of realizing micro-CT, including a stage mechanism 1, a first lifting mechanism 2, a first lifting seat 3 connected to the first lifting mechanism 2, and a first lifting seat 3 installed on the second lifting mechanism. A spacing adjustment mechanism 4 on the lifting base 3, and an x-ray emitting mechanism 5 and an x-ray receiving mechanism 6 connected to the spacing adjusting mechanism 4; the stage mechanism 1 is located between the x-ray emitting mechanism 5 and the x-ray receiving mechanism 6 Between the ray receiving mechanism 6, the stage mechanism 1 includes a first translation mechanism 11, a rotating mechanism connected with the first translation mechanism 11, and a carrying platform 12 connected with the rotating mechanism and u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com