Half-ship sea-crossing whole ship jacking method

A lifting and slipway technology, applied in the field of ships, can solve problems such as inability to remove, and achieve the effects of maintaining stability, large adjustment stroke, and strong resistance to lateral force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

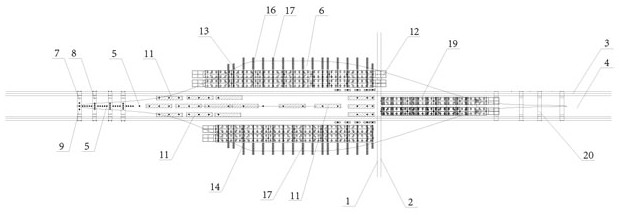

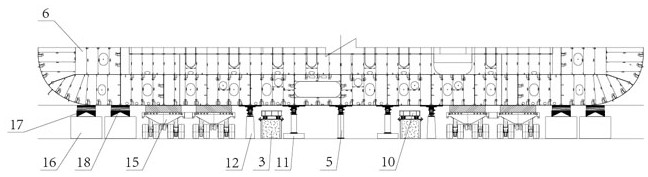

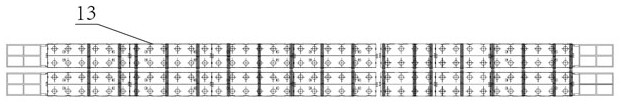

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0033]A method for lifting a half-ship across the sea, including a berth 1, a floating dock 2, a slideway 3, a channel 4, a circular pipe support 5, a hull 6, a first rib beam 7, a second rib beam 8, and a beam Bottom support 9, pulley 10, pad slide round pipe support 11, dock support 12, port axis pier group 13, starboard axis pier group 14, berth axis pier group 15, dock pier 16, pebble box 17 , pebble box pier wood 18, floating dock axis vehicle group 19, launching beam 20, the slipway 1 and the floating dock 2 are provided with a slideway 3 for providing a track, and the slideway 3 is provided with a channel 4 for providing In the moving space, the channel 4 is provided with a circular tube support 5 for providing support. The circular tube support 5 is located at the bottom of the horizontal centerline of the bow of the hull 6, and the bow of the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com