Cable reeling device

A cable reel and cable technology, applied in the direction of transportation and packaging, delivery of filamentous materials, thin material processing, etc., can solve the problems of time delay, need to replace the cable reel, waste of labor, etc., and achieve the effect of reducing the number of replacements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

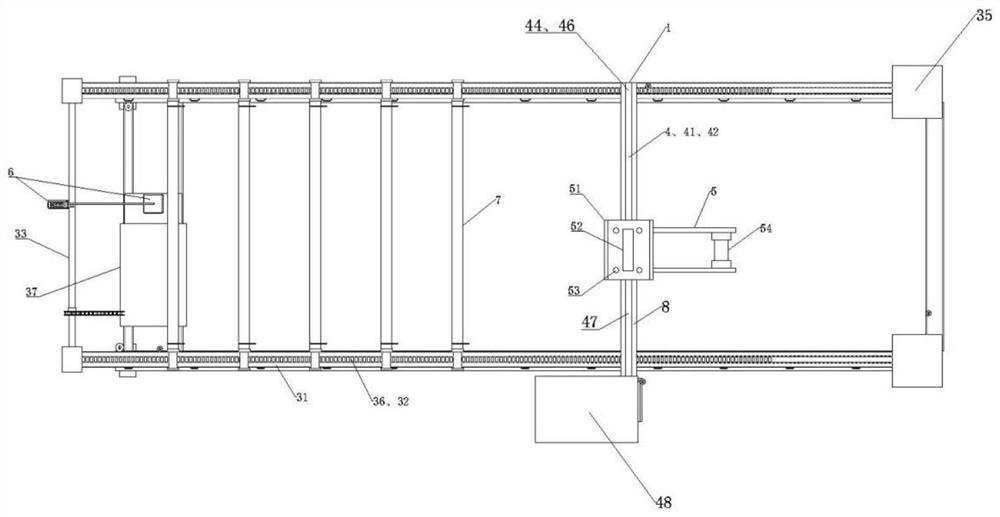

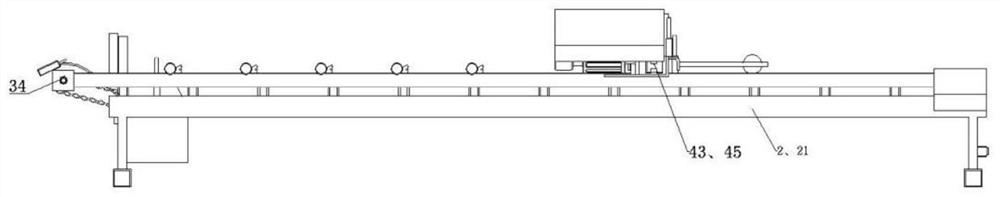

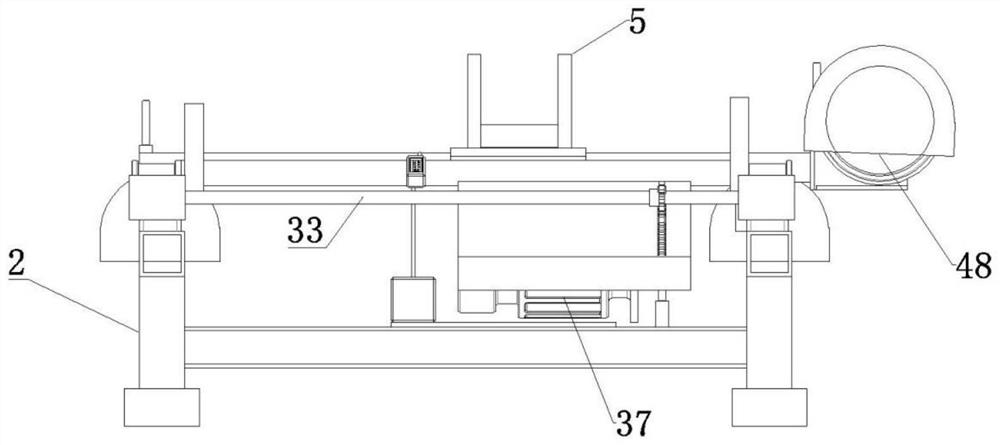

[0022] Example 1, such as Figure 1-3 As shown, a cable coiling device, the device (1) is arranged above a movable cable reel through a bracket (2), and the device (1) includes a longitudinal The drive unit (3), the transverse drive unit (4) capable of longitudinal movement on the longitudinal drive unit (3), the cable guide unit (5) capable of transverse movement on the transverse drive unit (4) and the longitudinal A drive controller (6) for the operation of the drive unit (3) and the transverse drive unit (4). The above-mentioned device (1) is set above a movable cable reel through the bracket (2), which belongs to the situation that the cable coiling area is not large enough. At this time, a movable cable reel passes through the device in the cable coiling area Carry out cable reeling, when the cable reel is full, push the movable cable reel full of cables away from the cable reel area, replace another movable cable reel and continue the cable reel, in this way, replace t...

Embodiment 2

[0023] Example 2, such as Figure 1-3 As shown, a cable coiling device, the device (1) is arranged above a plurality of fixed cable reels through a bracket (2), and the device (1) includes a longitudinal The drive unit (3), the transverse drive unit (4) capable of longitudinal movement on the longitudinal drive unit (3), the cable guide unit (5) capable of transverse movement on the transverse drive unit (4) and the longitudinal A drive controller (6) for the operation of the drive unit (3) and the transverse drive unit (4). The above-mentioned device (1) is arranged above a plurality of fixed cable reels through the bracket (2), which belongs to the situation that the cable coiling area is large enough. At this time, multiple cable reels are fixed in the cable coiling area and pass through the device Carry out the cable coiling work one by one, and leave the cable coiling area together after multiple cable drums are full of cables.

Embodiment 3

[0024] Example 3, such as Figure 1-3 As shown, the described longitudinal drive device (3) includes two longitudinal drive chain boxes (31) fixed on the two longitudinal beams (21) of the support (2) in a bolted manner, and each longitudinal drive chain The top of the box (31) is provided with a longitudinal guiding slit (32) along the longitudinal direction, a horizontal drive shaft (33) fixed on one end of the two longitudinal drive chain boxes (31) in a bearing connection mode, and in each longitudinal drive chain box Vertical driving sprocket (34) is respectively housed on the horizontal drive shaft (33) in (31), the longitudinal driven sprocket (35) that is fixed on the other end of two vertical driving chain boxes (31) with bearing connection mode, The vertical drive chain (36) that winds around each pair of corresponding vertical drive sprockets (34) and the vertical driven sprocket (35) and the vertical drive motor that drives the horizontal drive shaft (33) to rotate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com