Improved structure of peanut combined harvester conveying apparatus

A technology of combine harvester and conveying device, which is applied in the direction of excavator harvester, harvester, agricultural machinery and implements, etc., to achieve the effect of improving the working speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

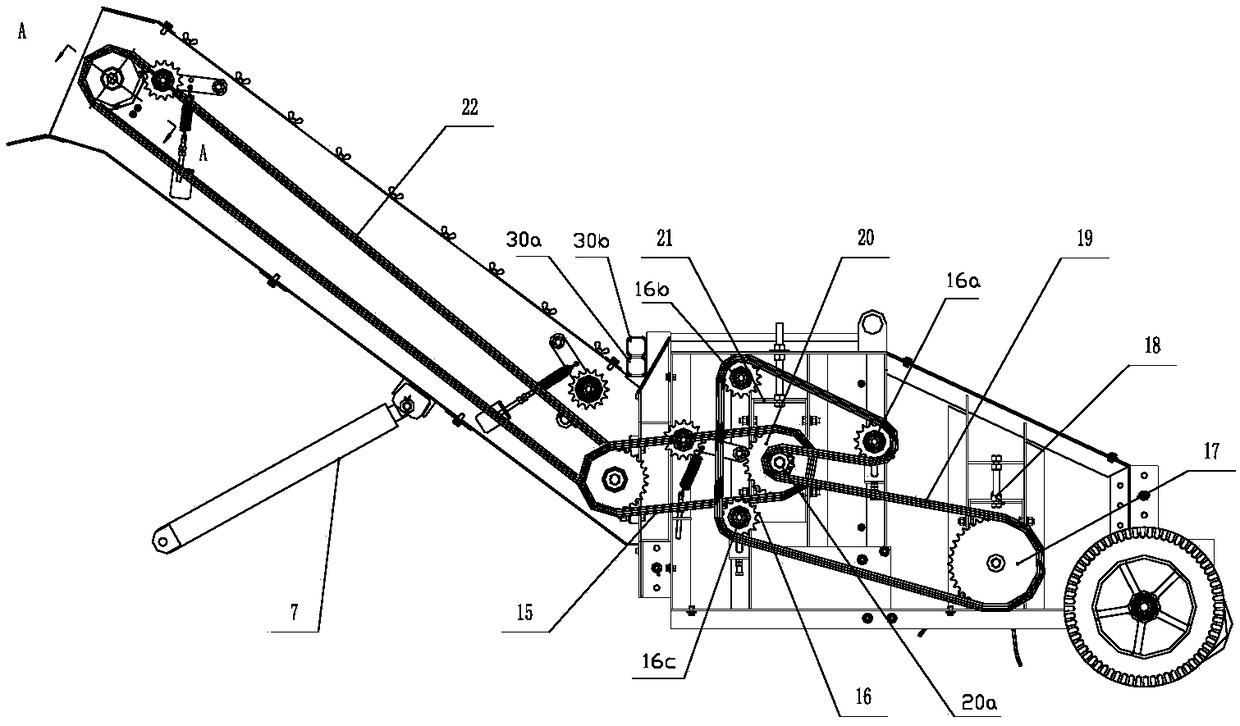

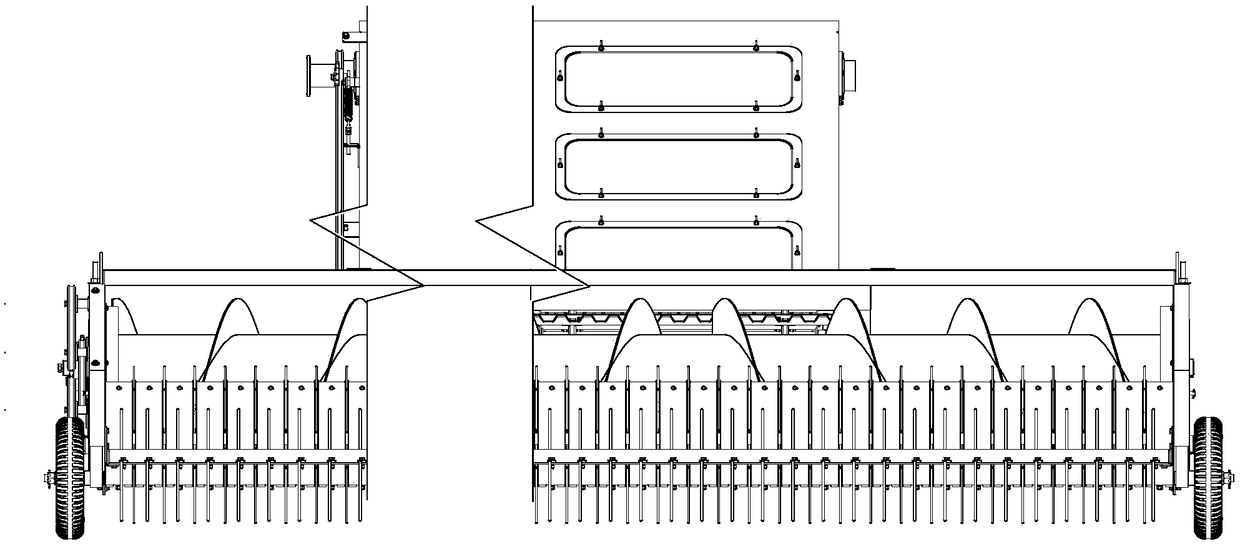

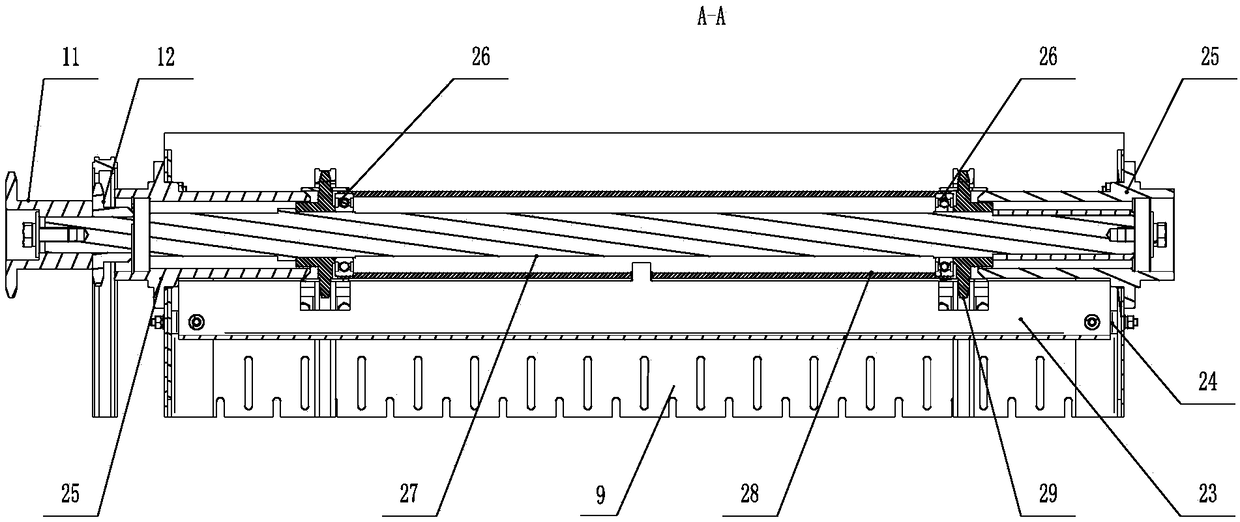

[0031] The structure of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0032]An improved structure of the conveying device of a peanut combine harvester. The tail part is obliquely upward to form a flat rectangular conveying trough. The front and rear parts are equipped with transmission shafts 27 horizontally and horizontally passing through the conveying trough shell. A pair of conveyer sprockets 29 are fixedly arranged on the drive shaft 27 at the side shell wall, two pairs of conveyer sprockets 29 are arranged with two circulating conveyer chains 10, and a large number of them are fixed on the two conveyer chains 10. A horizontal scraper bar 8 is placed horizontally, and a row of trapezoidal scrapers protrudes from the scraper bar 8. When the scraper bar 8 circulates to the bottom, the scraper end contacts the lower bottom plate 9 of the conveying trough, and the conveying trough One side of the housing is d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com