Winding device of compounding machine

A technology of a winding device and a laminating machine, applied in the field of laminating machines, can solve the problems of the collapse of non-woven fabrics and affecting the winding of non-woven fabrics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following descriptions are only preferred implementations of the present invention, and the scope of protection is not limited to this embodiment. All technical solutions under the idea of the present invention shall belong to the scope of protection of the present invention. At the same time, it should be pointed out that for those skilled in the art, some improvements and modifications without departing from the principle of the present invention should also be regarded as the protection scope of the present invention.

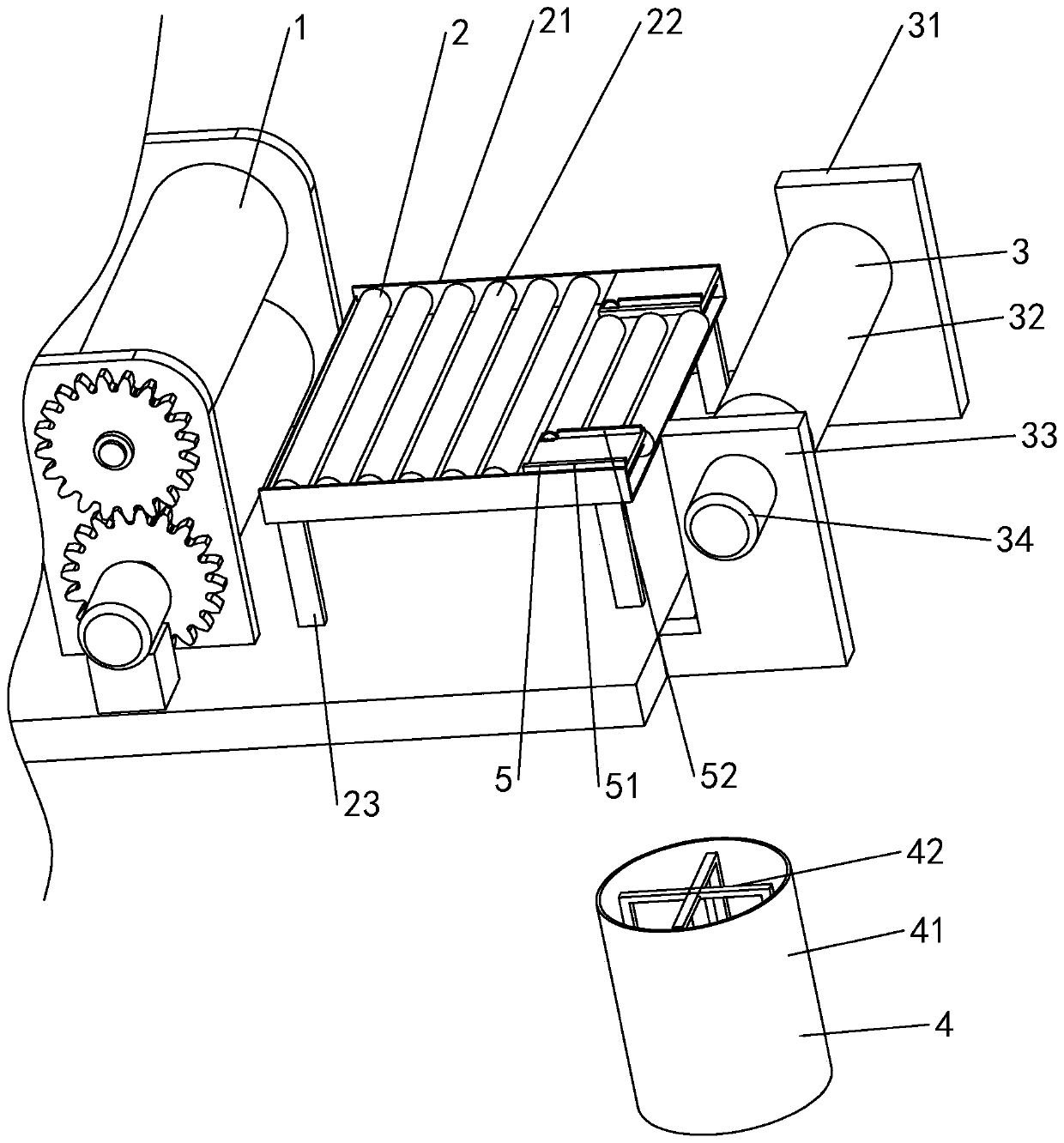

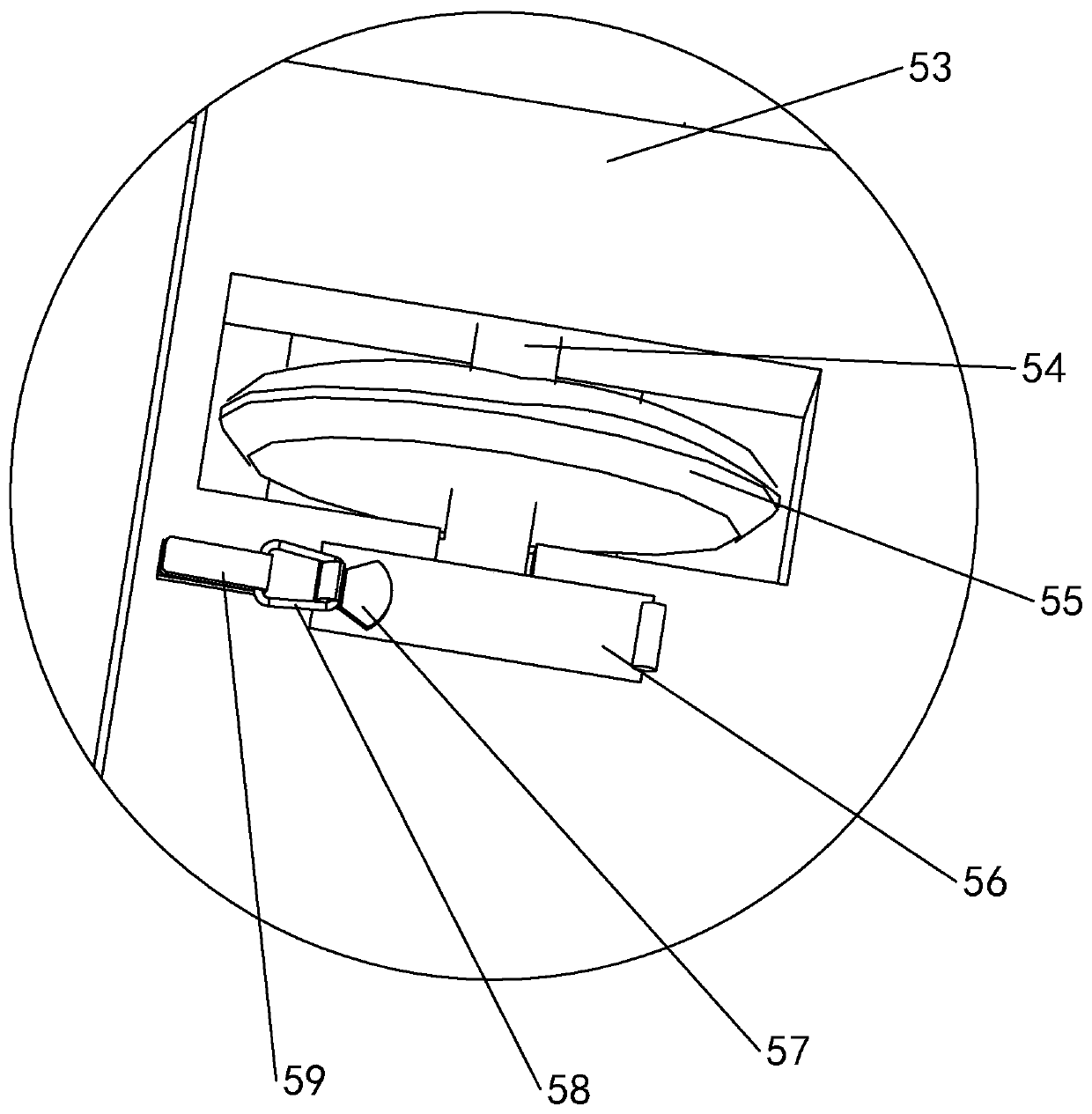

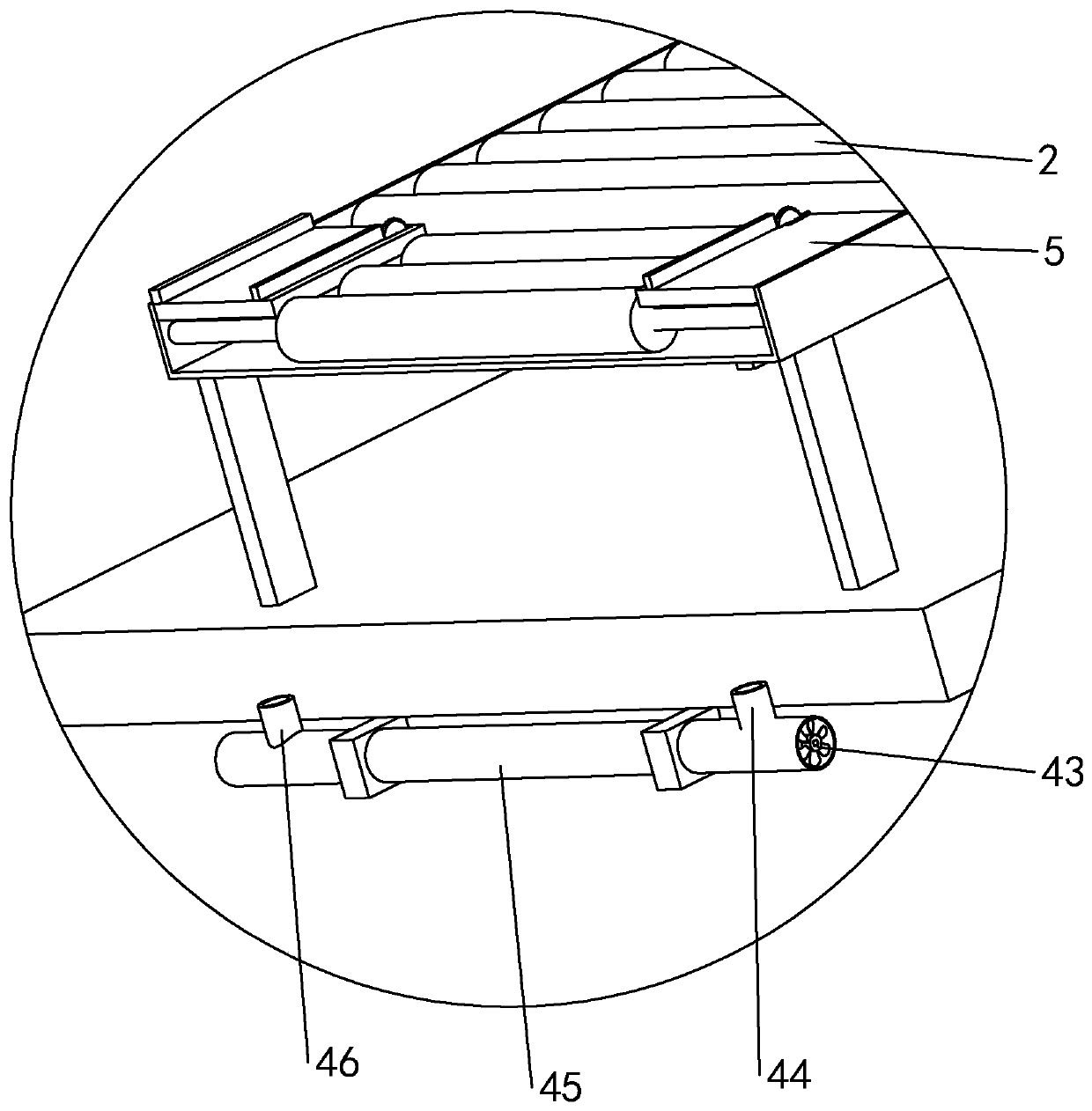

[0022] A winding device of a composite machine, see Figure 1 to Figure 4 , including the composite machine body 1, and also includes a transmission mechanism 2, a cutting mechanism 5, a winding mechanism 3 and a cloth collection mechanism 4, the transmission mechanism 2 includes a concave support frame 21, a transmission roller 22 and a support leg 23, and the support legs 23 are set to four One end of one and four support legs 23 is fixedly co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com