Rapid cooling process for annealing

A rapid cooling and process technology, which is applied in the field of cold-rolled plate production, can solve the problems of poor spray cooling effect, influence, and interference on the normal progress of spray cooling, the effect of spray cooling, etc., and achieve the effect of improving the quality and efficiency of spray cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

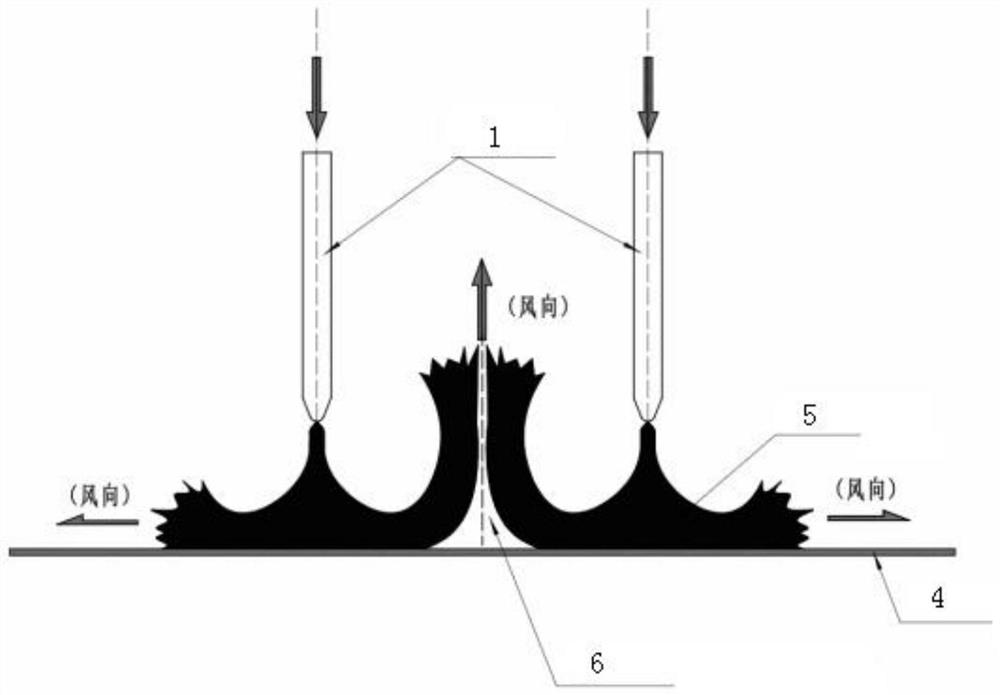

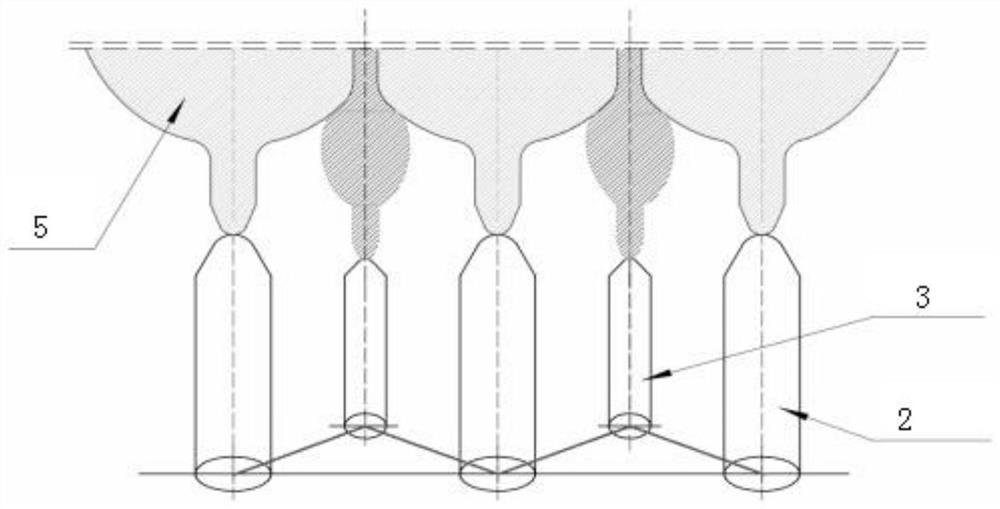

[0022] A rapid cooling process for annealing, realized by the following rapid cooling device:

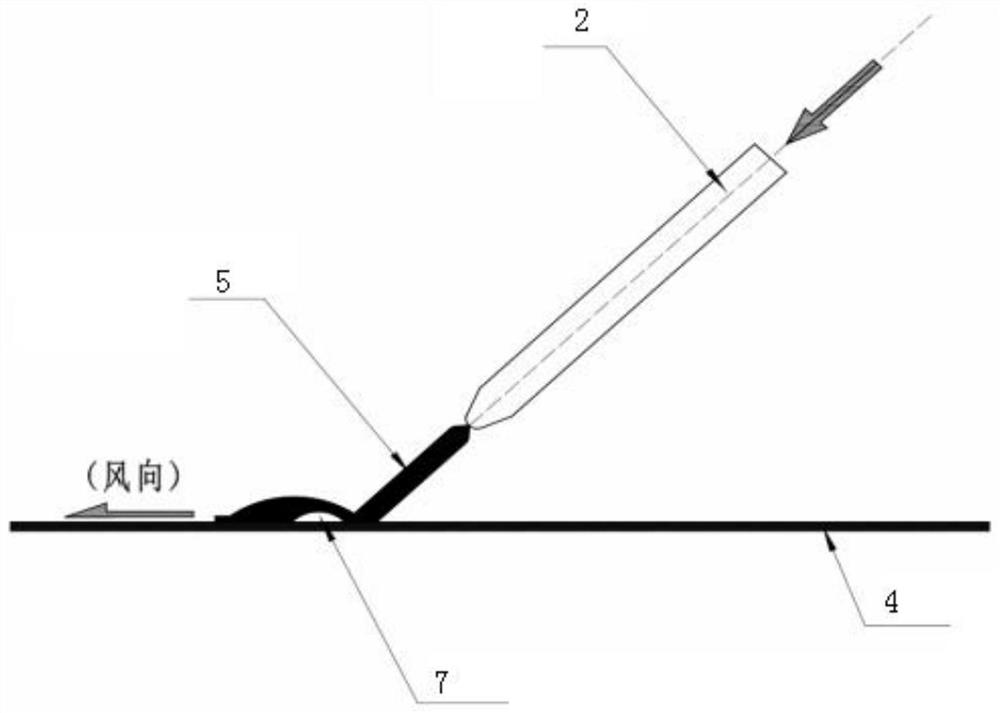

[0023] The rapid cooling device includes a nozzle, and the nozzle includes a main nozzle and a sub-nozzle, and a sub-nozzle is arranged between adjacent main nozzles, and the main nozzle and the sub-nozzle are inclined above the spray cooling plate Setting; the secondary nozzles are positioned behind and above the spraying direction of the adjacent two main nozzles;

[0024] The main steps of rapid cooling are as follows: both the main nozzle and the auxiliary nozzle spray the cooling medium to the cold-rolled sheet in the "oblique spray" spray cooling method, and the injection pressure of the auxiliary nozzle is 1 / 4 of the injection pressure of the main nozzle.

[0025] The spray angle between the main nozzle and the spray cooling plate is 45°.

[0026] The spray angle between the sub-nozzle and the spray-cooled plate is 45°.

Embodiment 2

[0028] A rapid cooling process for annealing, realized by the following rapid cooling device:

[0029] The rapid cooling device includes a nozzle, and the nozzle includes a main nozzle and a sub-nozzle, and a sub-nozzle is arranged between adjacent main nozzles, and the main nozzle and the sub-nozzle are inclined above the spray cooling plate Setting; the secondary nozzles are positioned behind and above the spraying direction of the adjacent two main nozzles;

[0030] The main steps of rapid cooling are as follows: both the main nozzle and the auxiliary nozzle spray the cooling medium to the cold-rolled sheet in the "oblique spray" spray cooling method, and the injection pressure of the auxiliary nozzle is 1 / 3 of the injection pressure of the main nozzle.

[0031] The spray angle between the main nozzle and the spray cooling plate is 30°.

[0032] The spray angle between the sub-nozzle and the spray-cooled plate is 30°.

Embodiment 3

[0034] A rapid cooling process for annealing, realized by the following rapid cooling device:

[0035] The rapid cooling device includes a nozzle, and the nozzle includes a main nozzle and a sub-nozzle, and a sub-nozzle is arranged between adjacent main nozzles, and the main nozzle and the sub-nozzle are inclined above the spray cooling plate Setting; the secondary nozzles are positioned behind and above the spraying direction of the adjacent two main nozzles;

[0036] The main steps of rapid cooling are as follows: both the main nozzle and the auxiliary nozzle spray the cooling medium to the cold-rolled sheet in the "oblique spray" spray cooling method, and the injection pressure of the auxiliary nozzle is 1 / 3 of the injection pressure of the main nozzle.

[0037] The spray angle between the main nozzle and the spray cooling plate is 60°.

[0038] The spray angle between the sub-nozzle and the spray-cooled plate is 60°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com