Material supermarket circulation supply scheduling method considering energy saving and punctuality

A scheduling method and material technology, applied in logistics, energy industry, biological models, etc., can solve problems such as difficult management of line-side inventory, poor emergency capacity, and reduced flexibility of assembly lines, etc., to achieve material supermarket cycle supply scheduling method And system responsibilities are clearly defined, inventory status is improved, and the effect of alleviating the space pressure on the line

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to make the technical means, creative features, goals and effects of the present invention easy to understand, the following will describe in detail the energy-saving and punctual material supermarket cycle supply scheduling method of the present invention in conjunction with the embodiments and accompanying drawings.

[0048]

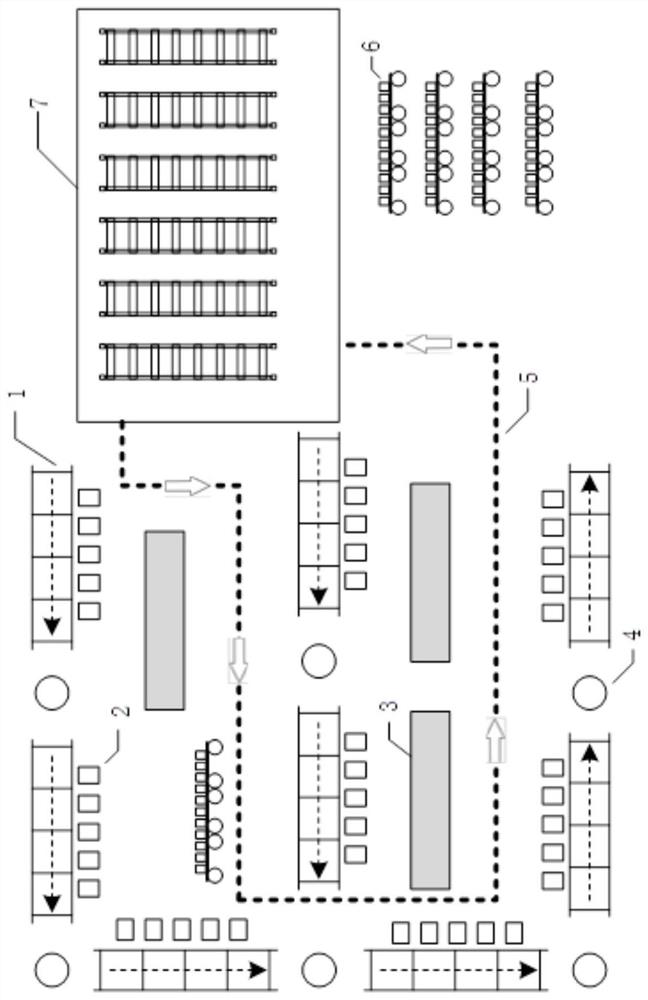

[0049] figure 1 It is a layout diagram of the material supermarket circulation supply dispatching system in the embodiment of the present invention.

[0050] The material supermarket circulation supply scheduling method in this embodiment considering energy saving and punctuality is implemented based on a material supermarket circulation supply scheduling system. Such as figure 1 As shown, the material supermarket cycle supply scheduling system includes assembly line 1, line buffer 2, material supermarket 3, inter-assembly line buffer 4, material supply route 5, material supply equipment 6, and central warehouse 7.

[0051] Among th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com