Method for producing a joint connection between a structural component made of a plastic and a metal component

A technology for metal parts and structural members, which is used in the field of establishing joint connections between structural members made of plastic and metal parts, can solve the problems of unknown wider application and limited applicability of connection technology, and achieves The effect of good adjustability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

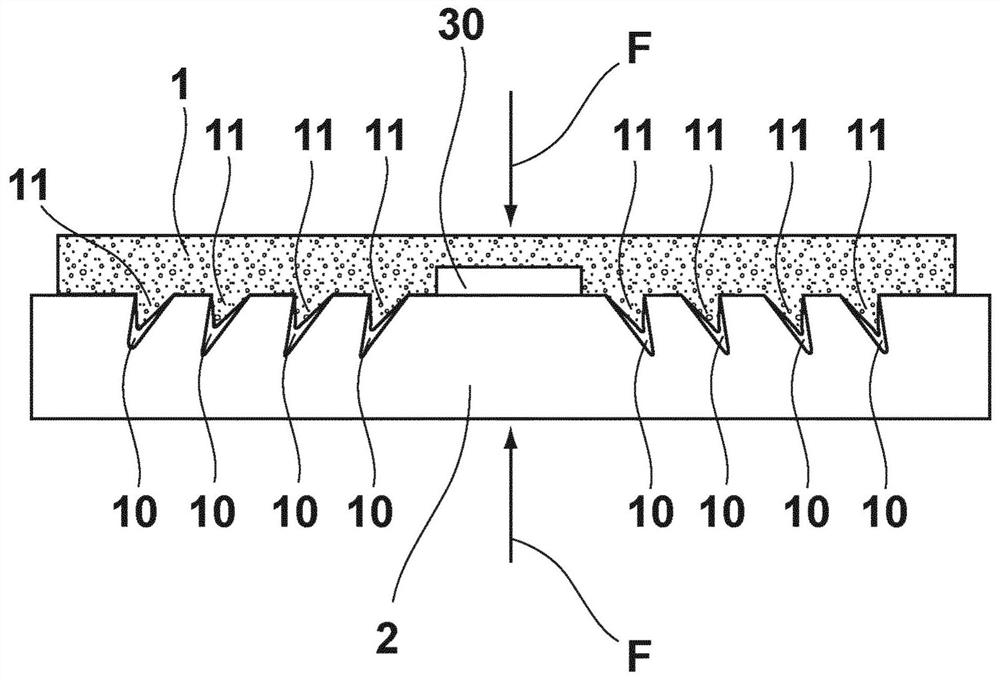

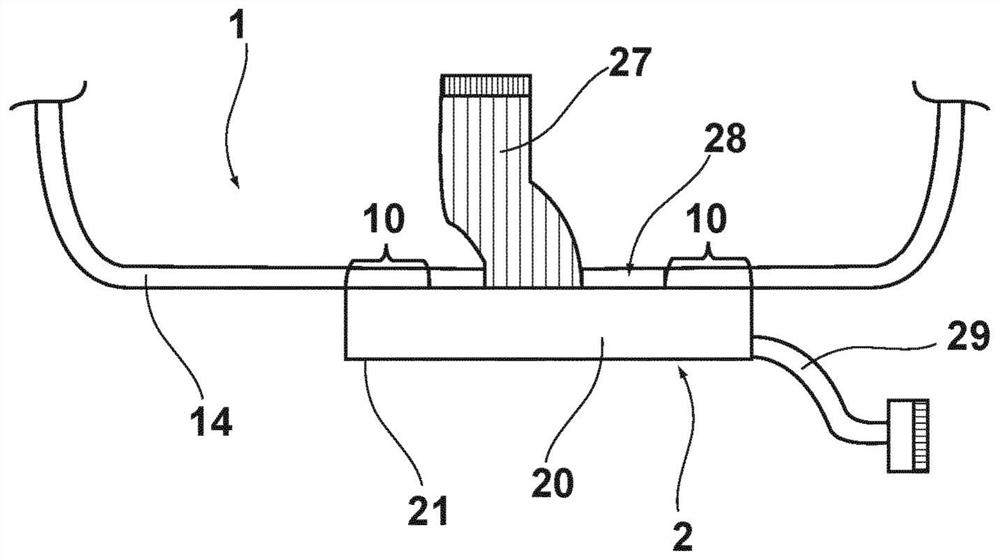

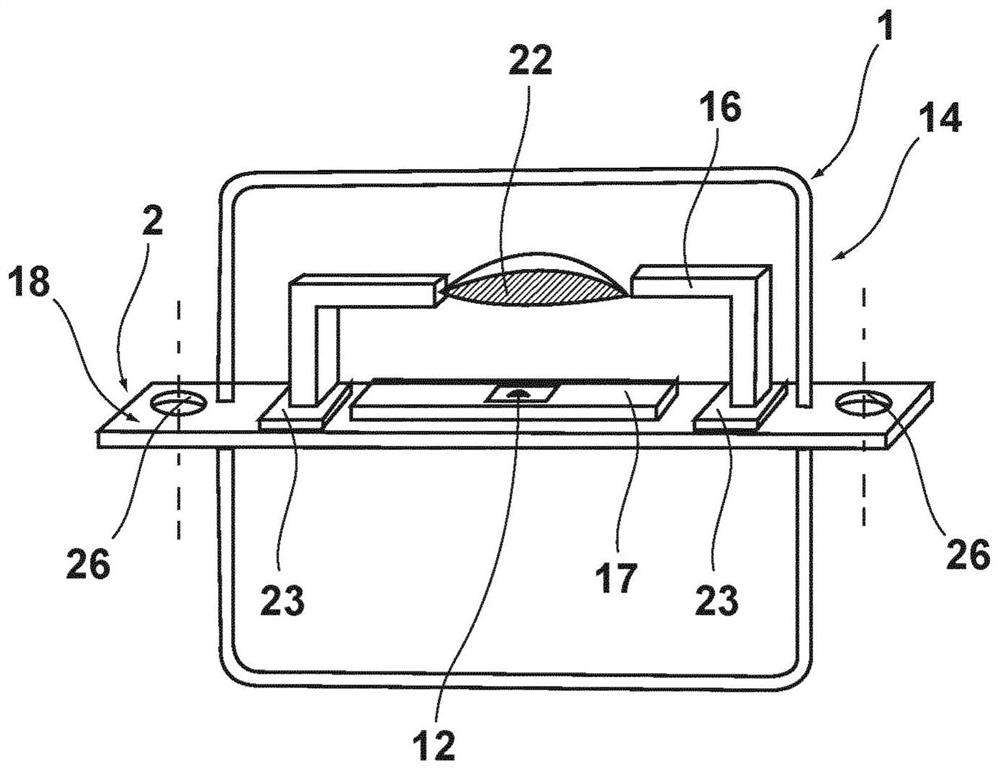

[0029] figure 1 A cross-sectional view of the joint between a structural component 1 made of plastic and a metal part 2 is shown. The structural component 1 made of plastic is shown abstractly and is therefore designed, not shown in more detail, as a carrier element, a holding element or, for example, as a housing of a lighting device of a vehicle, for example a headlight. The metal part 2 can form, for example, reinforcements, holders, holder tabs or the like.

[0030] A microstructure 10 is introduced into the surface of the metal part 2 which serves as a contact surface with the structural component 1 made of plastic, from which surface the microstructure enters obliquely into the body of the metal part 2 , wherein The inclination angles of the microstructures point in different directions relative to one another, by way of example a microstructure 10 on the left and an oppositely oriented microstructure 10 on the right are visible.

[0031] Microstructures 10 are introdu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com