A continuous molding method for thin terminals

A forming method and terminal technology, which are applied in the field of stamping processing, can solve the problems of structural deformation and easy punching of slender terminals, and achieve the effect of meeting the accuracy requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0033] A thin terminal continuous molding method of the present invention, the steps include:

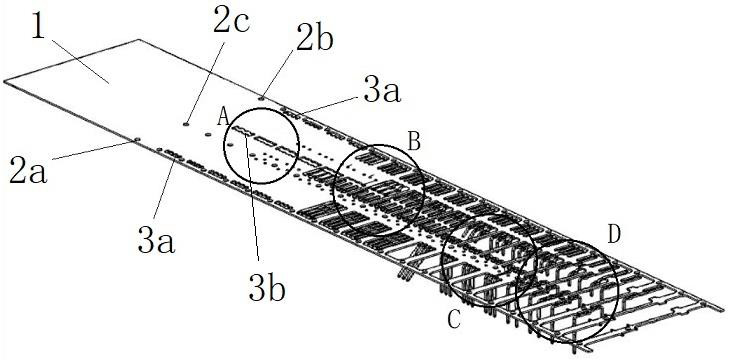

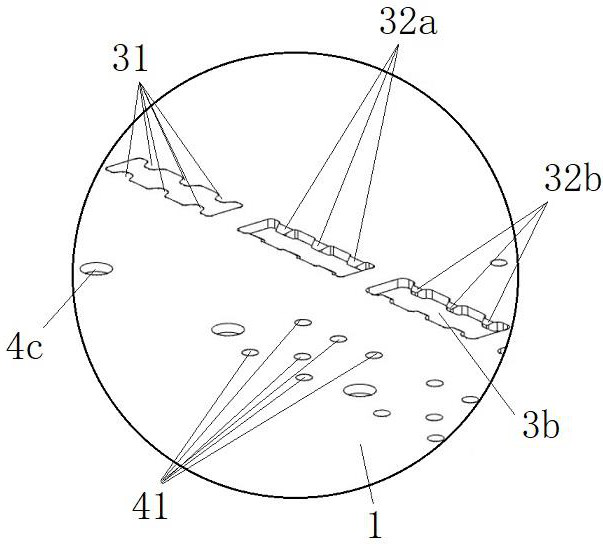

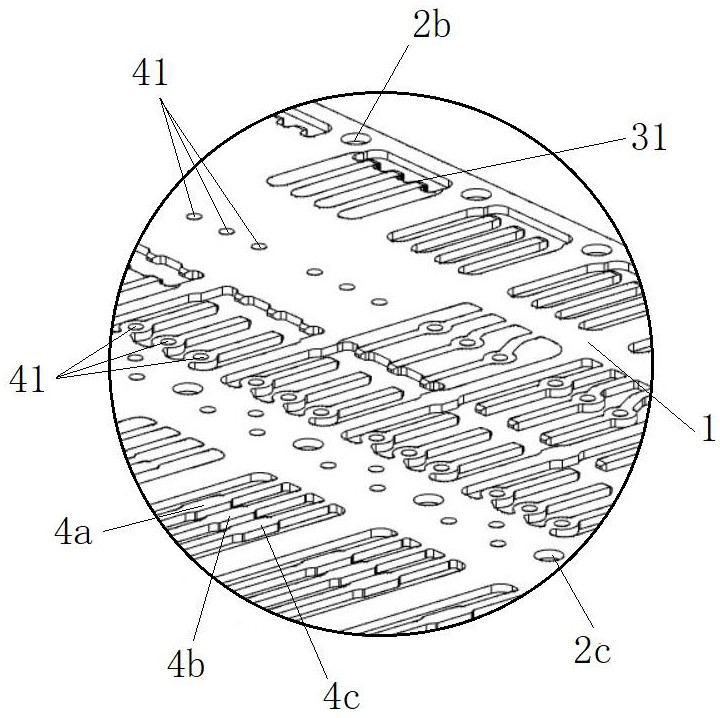

[0034] ① Use the head end and both sides of the metal strip 1 as the positioning, and cut out several positioning holes within the range of the processing unit. The design of the processing unit range includes an I-shaped connection reserve area and a product forming area between adjacent connection reserve areas. The positioning holes are located in the connection reserve area, and the product forming area is used to process terminal products. Such as figure 1 As shown, the positioning hole is used as the positioning datum during the stamping of the back section. The positioning holes include a first positioning hole 2a located on one side of the connecting reserved area, a second positioning hole 2b located on the other side of the connecting reserved area, and a third positioning hole 2c located in the middle of the connecting reserved area. The distance from the third position...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com