Structure force bearing type mould plate construction unit

A load-bearing, formwork component technology, applied in building components, floor slabs, building structures, etc., can solve the problems of inconvenient pipeline penetration, low shear resistance, and poor integrity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

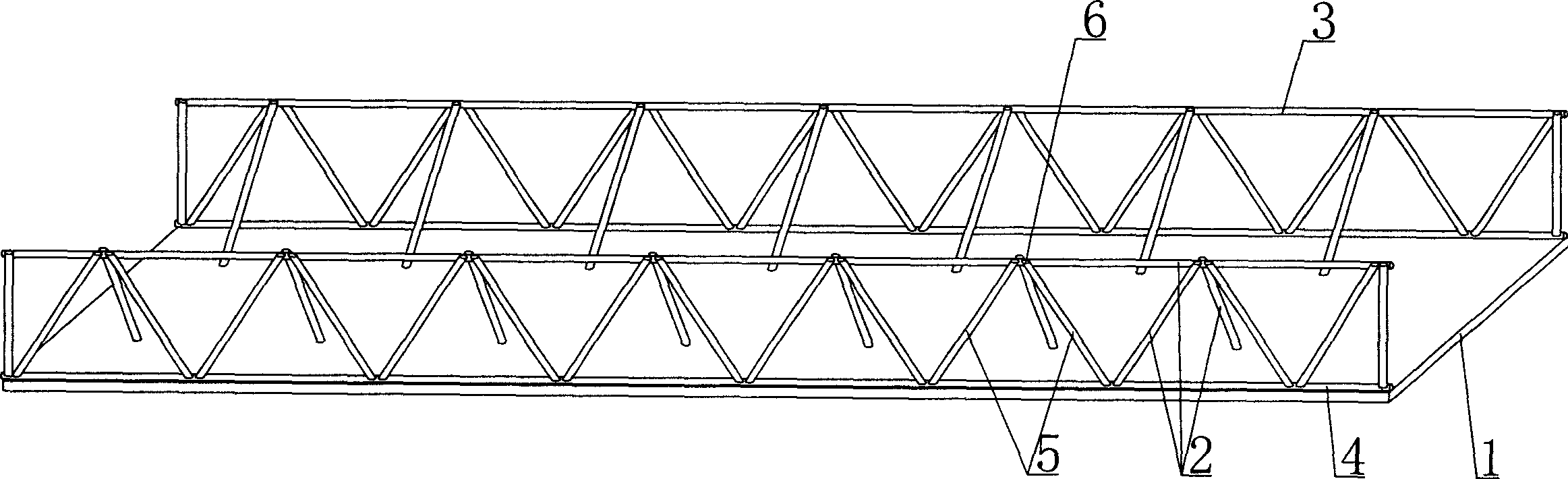

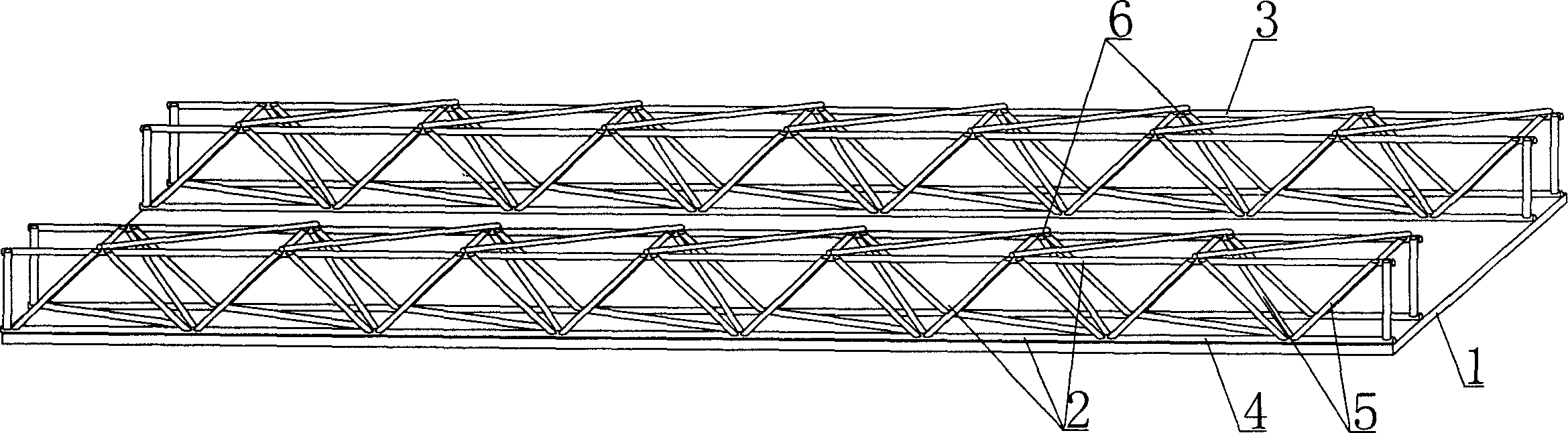

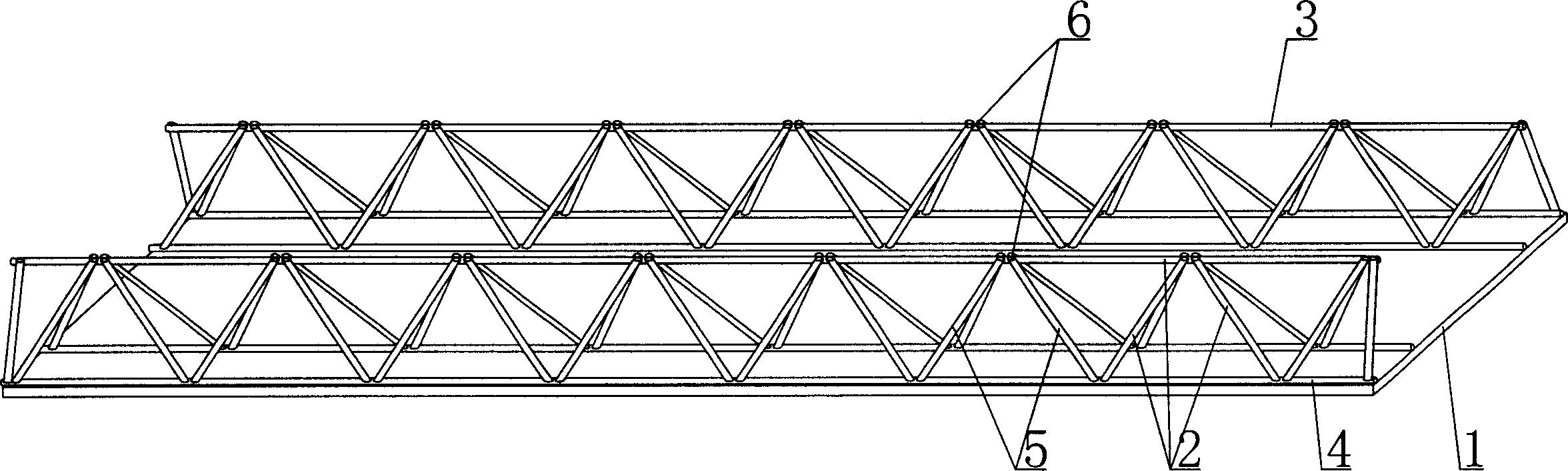

[0077] As shown in the drawings, the present invention includes a formwork 1, which is characterized in that it also includes at least one network frame 2. The network frame 2 is arranged on the formwork 1 and connected to form a whole. The network frame 2 is provided with an upper chord 3 and a lower chord 4. 1. Webs 5, the webs 5 are connected with the upper chord 3 and the lower chord 4, and at least three webs 5 are connected at at least one node 6, forming a net-like three-dimensional rod structure with each other. In each accompanying drawing, 1 is a template, 2 is a network frame, 3 is an upper chord, 4 is a lower chord, 5 is a web, and 6 is a node. In the following drawings, those with the same number have the same description. Such as figure 1 As shown, the structural load-bearing formwork member includes a formwork 1, and the formwork member ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com