A kind of carcass drum flexible sleeve opening method

A drum flexible and flexible sleeve technology, applied in the field of carcass drum flexible sleeve opening, can solve the problems of size and shape change, suction cup device cannot be installed on the drum body, offset, etc., and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

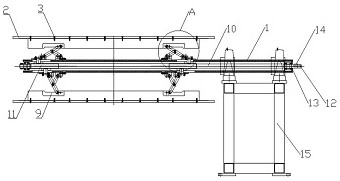

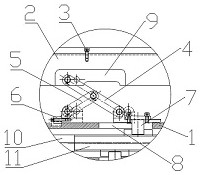

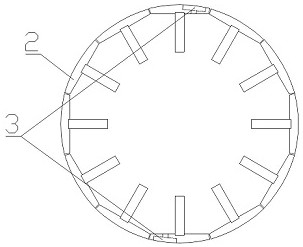

[0019] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0020] like figure 1 , figure 2 , image 3 , Figure 4 As shown in the figure, a method for perforating the flexible sleeve of the carcass drum proposed by the present invention is implemented by a device for opening the flexible sleeve of the carcass drum. 2. There are several and are arranged around the main shaft 1 in a circular shape with the main shaft 1 as the center. Any two of the supporting plates 2 that are oppositely arranged with the main shaft 1 as the center are provided with a number of positioning holes 3 along the axis of the main shaft 1. The expansion connection assembly is connected between the support plate 2 and the main shaft 1 , and the expansion connection assembly can drive the support plate 2 to expand relative to the main shaft 1 under the action of the drive assembly.

[0021] In the present invention, the carcass drum flexible sleeve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com