Industrial robot dismounting and mounting arm with high safety performance

A technology of industrial robots and safety performance, applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve problems such as manual operation hazards, achieve the effect of eliminating potential safety hazards and improving operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

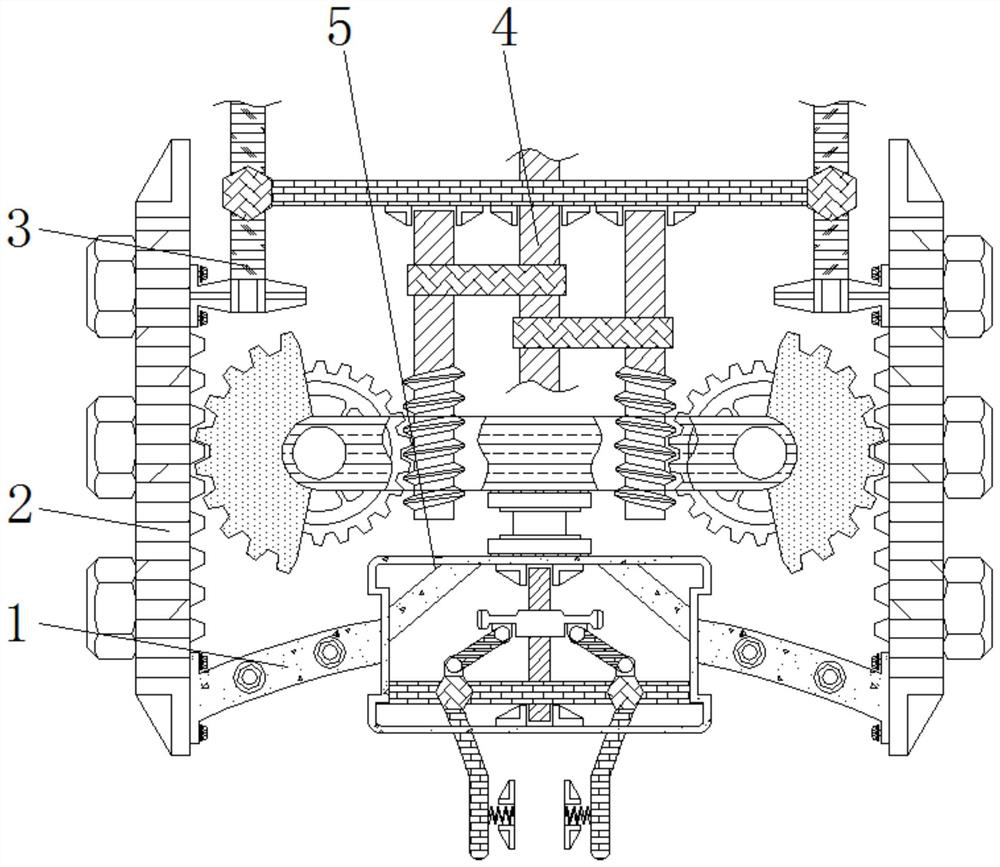

[0022] see figure 1 , figure 2 , a disassembly and installation arm of an industrial robot with high safety performance, including a fixed plate 1, a side plate 2 is welded on the side of the fixed plate 1, a limit column 3 is welded on the inner side of the side plate 2, and two side plates 2 are provided to fix The middle point of the plate 1 is centered and distributed symmetrically, and are welded on the left and right sides of the fixed plate 1 in a vertical state, and the inner side of the side plate 2 is provided with teeth; there are two limit posts 3, which are welded in a vertical state On the inside of the left and right side plates 2; the periphery of the limit post 3 is provided with a driving mechanism 4;

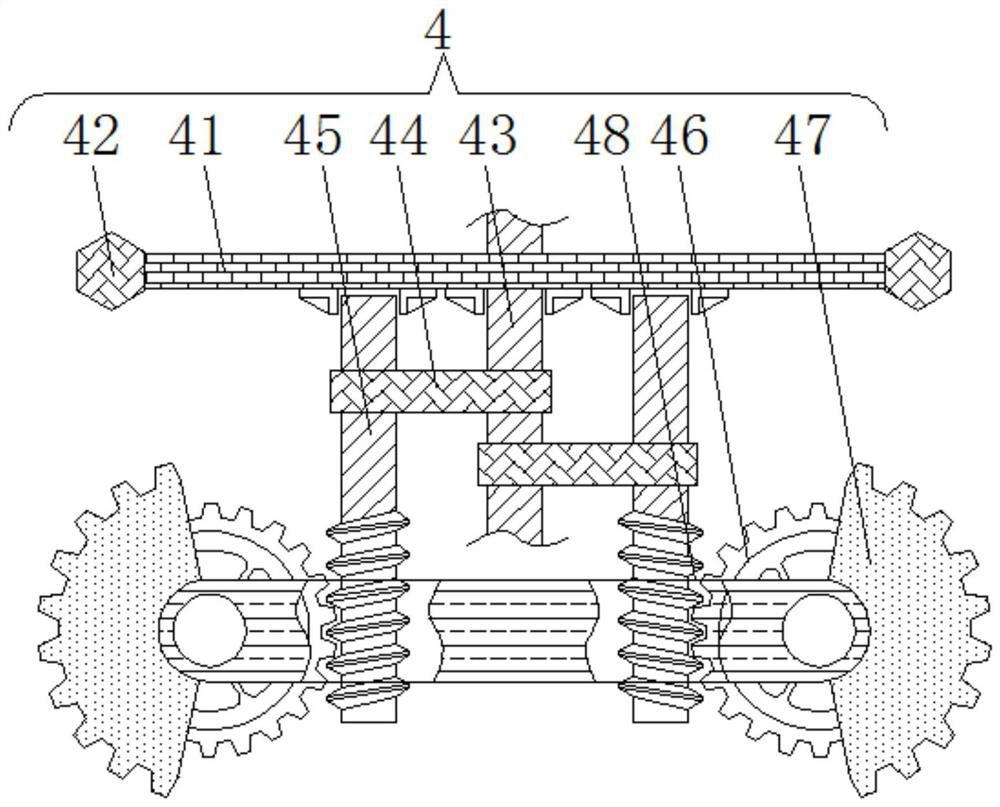

[0023] The driving mechanism 4 comprises a limit plate 41, the side of the limit plate 41 is welded with a limit sleeve 42, the middle of the limit plate 41 is connected with a drive shaft 43, the periphery of the drive shaft 43 is sleeved with a belt 44, an...

Embodiment 2

[0026] see figure 1 , image 3 , a disassembly and installation arm of an industrial robot with high safety performance, including a fixed plate 1, a side plate 2 is welded on the side of the fixed plate 1, a limit column 3 is welded on the inner side of the side plate 2, and two side plates 2 are provided to fix The middle point of the plate 1 is centered and distributed symmetrically, and are welded on the left and right sides of the fixed plate 1 in a vertical state, and the inner side of the side plate 2 is provided with teeth; there are two limit posts 3, which are welded in a vertical state On the inside of the left and right side plates 2; the periphery of the limit post 3 is provided with a driving mechanism 4;

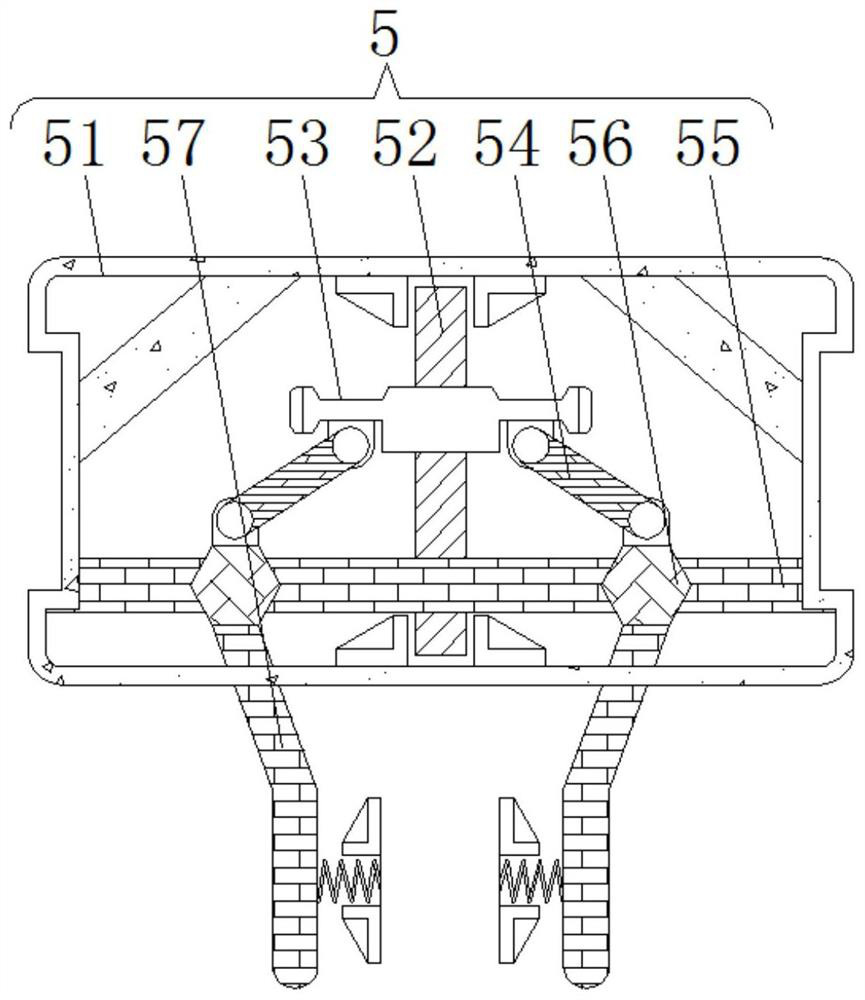

[0027] The bottom of the driving mechanism 4 is provided with a clamping mechanism 5; the clamping mechanism 5 includes a device shell 51, the inside of the device shell 51 is connected with a screw rod 52 for rotation, the outer thread of the screw rod 52 is...

Embodiment 3

[0029] see Figure 1-3 , a disassembly and installation arm of an industrial robot with high safety performance, including a fixed plate 1, a side plate 2 is welded on the side of the fixed plate 1, a limit column 3 is welded on the inner side of the side plate 2, and two side plates 2 are provided to fix The middle point of the plate 1 is centered and distributed symmetrically, and are welded on the left and right sides of the fixed plate 1 in a vertical state, and the inner side of the side plate 2 is provided with teeth; there are two limit posts 3, which are welded in a vertical state On the inside of the left and right side plates 2; the periphery of the limit post 3 is provided with a driving mechanism 4;

[0030] The driving mechanism 4 comprises a limit plate 41, the side of the limit plate 41 is welded with a limit sleeve 42, the middle of the limit plate 41 is connected with a drive shaft 43, the periphery of the drive shaft 43 is sleeved with a belt 44, and the inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com