Automatic assembling device for truck traction disc

An automatic assembly device and traction disc technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of low work and inability to further improve production efficiency, so as to improve production efficiency, increase the speed of material supply, and improve The effect of assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

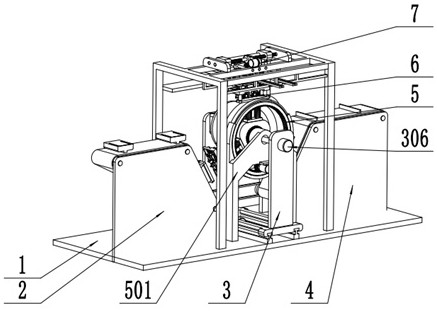

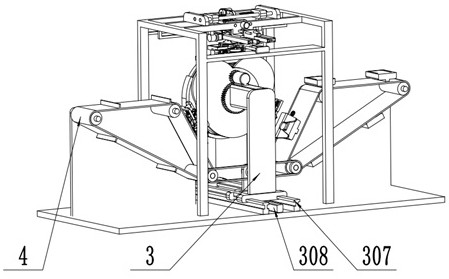

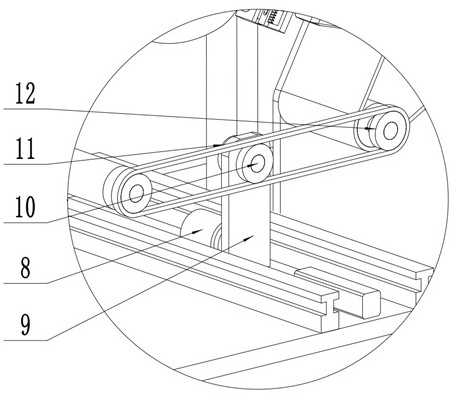

[0025] Embodiment: as shown in the figure, figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 In the shown automatic assembly device for traction pulleys of trucks, conveyor belt rollers and conveyor belts are set on both the feed frame 2 and the discharge frame 4, the conveyor belt is set on the conveyor belt rollers, and the conveyor belt of the feed frame 2 is used to position the workpiece The clamping device, the workpiece is placed on the clamping device when feeding, and the workpiece is separated from the clamping device when the workpiece is extracted upward by external force. The feed frame 2 and the discharge frame 4 are respectively arranged at both ends of the installation base plate 1, and the feed frame 2 and the sliding mechanism 3 are powered by the power source at the same time, and the workpiece is transmitted at the same time; the slide mechanism 3 is arranged on the installation base plate 1 , The sliding mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com