Metal cold rolling and pressing composite manufacturing device and using method thereof

A manufacturing device and metal technology, which is applied in the field of metal cold rolling and pressing composite manufacturing devices, can solve the problems of scratching metal plates and difficult separation of metal plates, and achieve the effect of improving the bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

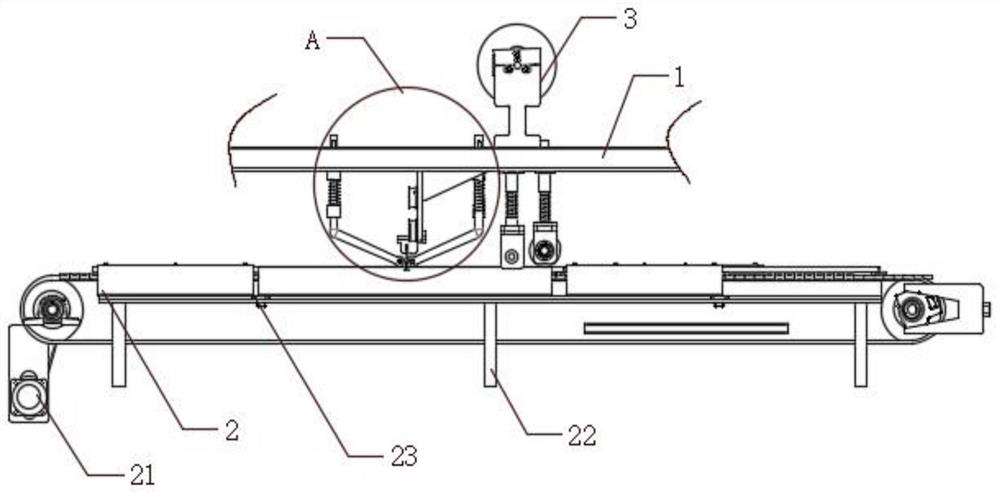

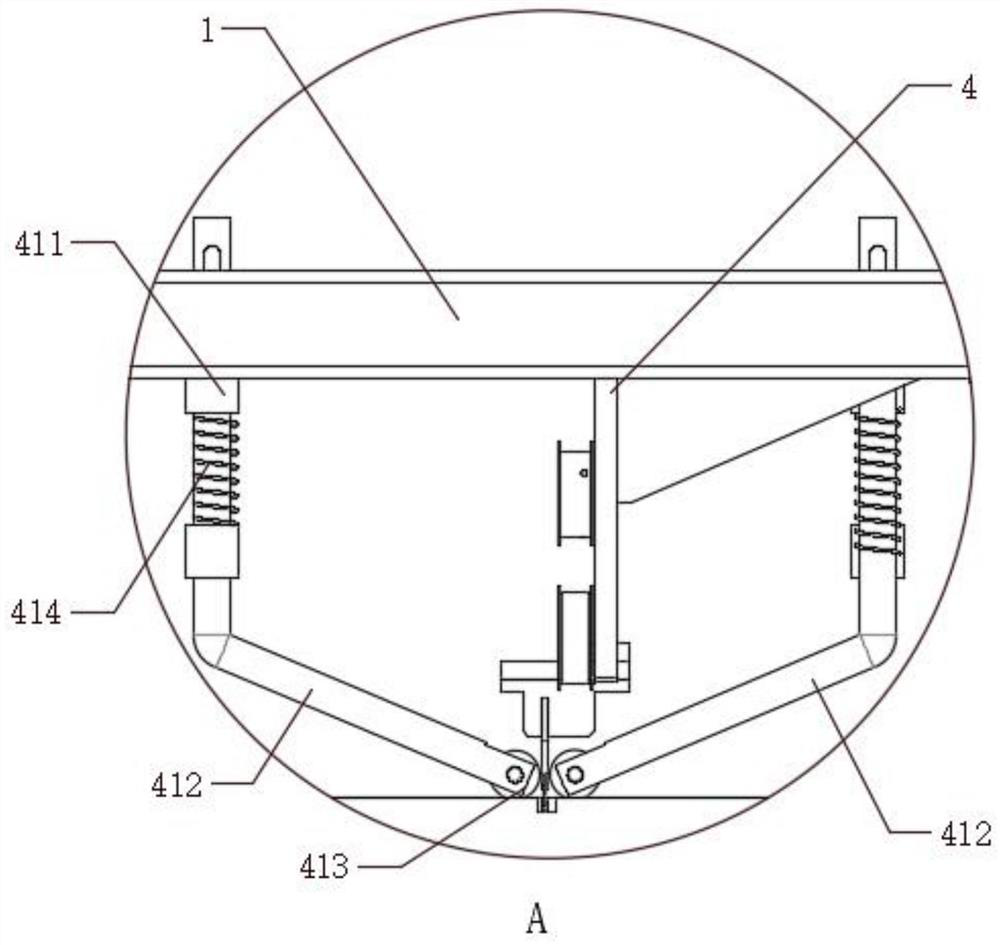

[0046] like Figure 1-7 As shown, a metal cold-rolled composite manufacturing device of the present invention includes a transport mechanism 2, and the transport mechanism 2 is provided with several guide rollers, and metal plates are placed on the guide rollers to guide the metal plates to move horizontally in the transport mechanism 2. , the top of the transport mechanism 2 is provided with a connecting frame 1, a film covering mechanism 3, and a material pressing mechanism 4, and the film covering mechanism 3 is arranged on the right side of the material pressing mechanism 4, and the film covering mechanism 3, the material pressing mechanism 4 are all connected with the connecting frame 1, the film covering mechanism 3 is used to unfold the film and align with the metal plate, and the bottom of the pressing mechanism 4 is in rolling contact with the film coated metal plate.

[0047] When the metal plate is transported on the transport mechanism 2, the surface of the metal p...

Embodiment 2

[0053] This embodiment is a further improvement of the previous embodiment, such as Figure 1-7 As shown, a metal cold-rolled composite manufacturing device of the present invention includes a transport mechanism 2, and the transport mechanism 2 is provided with several guide rollers, and metal plates are placed on the guide rollers to guide the metal plates to move horizontally in the transport mechanism 2. , the top of the transport mechanism 2 is provided with a connecting frame 1, a film covering mechanism 3, and a material pressing mechanism 4, and the film covering mechanism 3 is arranged on the right side of the material pressing mechanism 4, and the film covering mechanism 3, the material pressing mechanism 4 are all connected with the connecting frame 1, the film covering mechanism 3 is used to unfold the film and align with the metal plate, and the bottom of the pressing mechanism 4 is in rolling contact with the film coated metal plate.

[0054] When the metal plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com