Low-grade non-oriented electrical steel and manufacturing method thereof

A technology of grain-oriented electrical steel and a manufacturing method, applied in the direction of temperature control, etc., can solve the problems of poor rolling stability of low-grade non-oriented electrical steel, affecting the size and shape accuracy of hot-rolled coils of low-grade non-oriented electrical steel, etc. Improves dimensional and shape accuracy, and stabilizes the effect of finishing rolling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

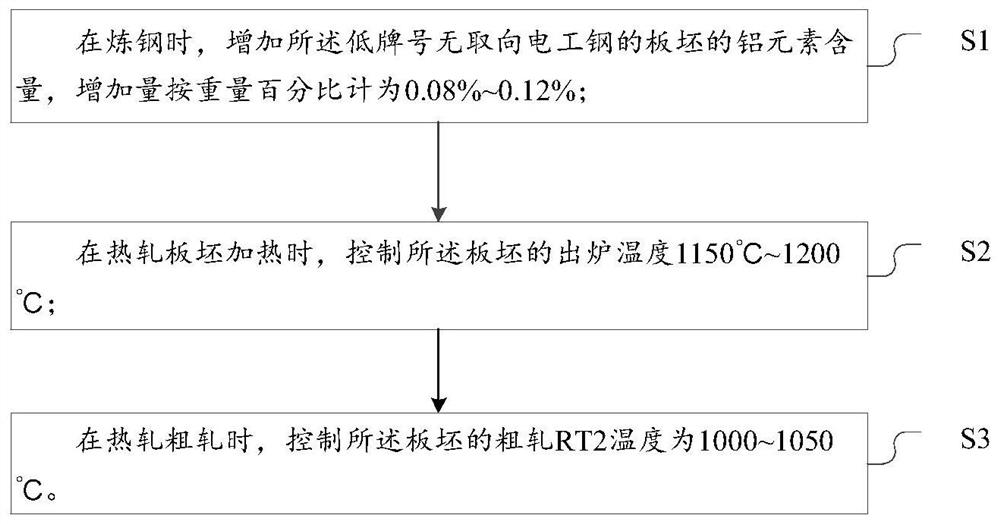

Method used

Image

Examples

Embodiment 1

[0043] The scheme provided by the present invention is applied to 50W1000, and a certain batch is rolled 22 coils altogether, and its process control is as follows:

[0044] Al element content: 0.9% to 1.1%;

[0045] Slab temperature control: 1153~1172℃;

[0046] Rough rolling RT2 temperature control: 1027~1043℃;

[0047] Temperature control of finish rolling and finishing rolling: 907~932℃;

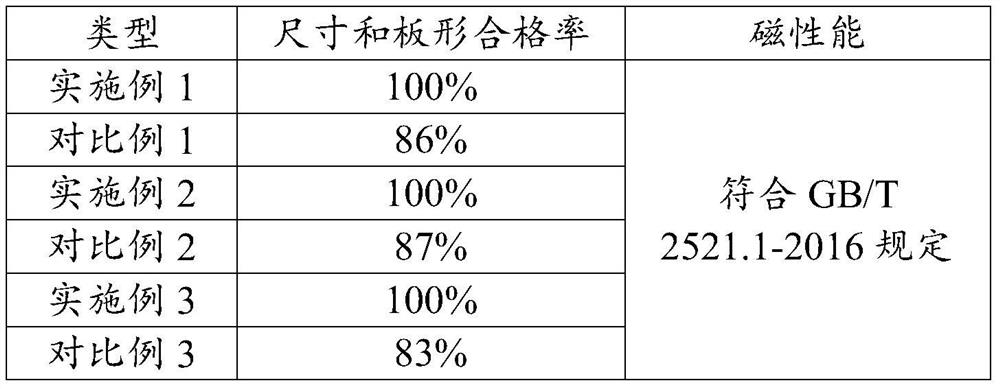

[0048] After the hot rolling is completed, the size and shape qualification rate of the coil are counted, and the magnetic properties are tested according to the requirements of GB / T 2521.1-2016.

Embodiment 2

[0050] The scheme provided by the present invention is applied to 50W800, and a certain batch is rolled 32 volumes altogether, and its process control is as follows:

[0051] Al element content: 1.4% to 1.6%;

[0052] Slab temperature control: 1164~1198℃;

[0053] Rough rolling RT2 temperature control: 1008~1038℃;

[0054] Temperature control of finish rolling and finishing rolling: 901~938℃;

[0055] After the hot rolling is completed, the size and shape qualification rate of the coil are counted, and the magnetic properties are tested according to the requirements of GB / T 2521.1-2016.

Embodiment 3

[0057] The scheme provided by the present invention is applied to 50W1300, and a certain batch is rolled 30 volumes altogether, and its process control is as follows:

[0058] Al element content: 0.6% to 1.0%;

[0059] Slab temperature control: 1151~1179℃;

[0060] Rough rolling RT2 temperature control: 1021~1047℃;

[0061] Temperature control of finish rolling and finishing rolling: 901~938℃;

[0062] After the hot rolling is completed, the size and shape qualification rate of the coil are counted, and the magnetic properties are tested according to the requirements of GB / T 2521.1-2016.

[0063] Corresponding to Embodiments 1 to 3, the historical steel coil production data before applying the scheme of the present invention are counted, specifically as follows:

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com