A kind of low-grade non-oriented electrical steel and its manufacturing method

A technology of oriented electrical steel and manufacturing method, applied in the direction of temperature control, etc., can solve the problems of poor rolling stability of low-grade non-oriented electrical steel, affecting the size and shape accuracy of low-grade non-oriented electrical steel hot-rolled coils, and achieving Effects of improving dimension and shape accuracy and stabilizing the finish rolling process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

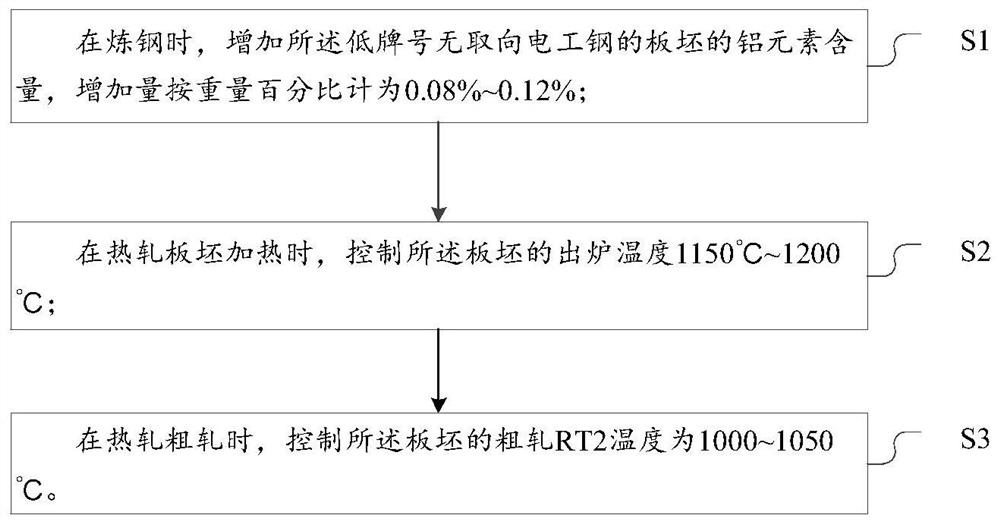

[0043] The scheme provided by the invention is applied to 50W1000, and a batch of 22 rolls is rolled in total, and its process control is as follows:

[0044] Al element content: 0.9%~1.1%;

[0045] Slab temperature control: 1153~1172℃;

[0046] Rough rolling RT2 temperature control: 1027~1043℃;

[0047] Finish rolling and finishing rolling temperature control: 907~932℃;

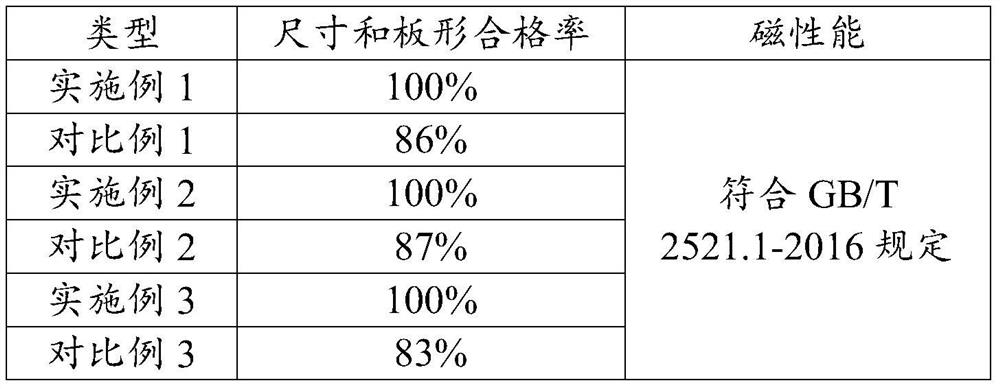

[0048] After the hot rolling is completed, the size of the coil and the qualified rate of the plate shape are counted, and the magnetic properties are tested according to the requirements of GB / T 2521.1-2016.

Embodiment 2

[0050] The scheme provided by the present invention is applied to 50W800, and a batch of 32 rolls is rolled in total, and its process control is as follows:

[0051] Al element content: 1.4%~1.6%;

[0052] Slab temperature control: 1164~1198℃;

[0053] Rough rolling RT2 temperature control: 1008~1038℃;

[0054] Finish rolling and finishing rolling temperature control: 901~938℃;

[0055] After the hot rolling is completed, the size of the coil and the qualified rate of the plate shape are counted, and the magnetic properties are tested according to the requirements of GB / T 2521.1-2016.

Embodiment 3

[0057] The scheme provided by the invention is applied to 50W1300, and a batch of 30 rolls is rolled in total, and its process control is as follows:

[0058] Al element content: 0.6%~1.0%;

[0059] Slab temperature control: 1151~1179℃;

[0060] Rough rolling RT2 temperature control: 1021~1047℃;

[0061] Finish rolling and finishing rolling temperature control: 901~938℃;

[0062] After the hot rolling is completed, the size of the coil and the qualified rate of the plate shape are counted, and the magnetic properties are tested according to the requirements of GB / T 2521.1-2016.

[0063] Corresponding to Examples 1 to 3, the historical steel coil production data before applying the solution of the present invention is counted, and the details are as follows:

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com