Fragrant environment-friendly coating and preparation method of wall cloth coating of fragrant environment-friendly coating

An environmentally friendly coating and aromatic technology, applied in the direction of textiles, papermaking, building components, etc., to achieve the effects of increasing popularity, improving product grades, and adding value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

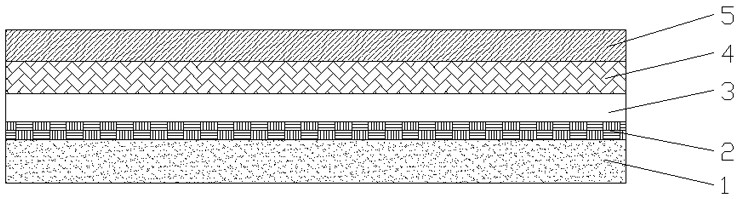

Image

Examples

Embodiment 1

[0035] The technical solution adopted in this embodiment is: the preparation process is as follows:

[0036] S1: After coating the base fabric with waterproof agent, drying and setting;

[0037] S2: Prepare an environmentally friendly paint with a fresh marine fragrance, and dry the obtained paint after scraping it on the fabric of S1; wherein the paint includes the following components by weight fraction:

[0038] Pure acrylate soft emulsion: 30-40 parts

[0039] Pure acrylate hard emulsion: 4-6 parts

[0040] Water: 65-75 parts

[0041] Fresh Ocean Microencapsulated Fragrance: 1 serving

[0042] Thickener: 0.1-0.2 parts

[0043] S3: The wall covering obtained in the above step S2 is coated with an intermediate layer and a surface layer to obtain a wall covering.

Embodiment 2

[0045] The difference between this embodiment and Example 1 is that the component content in the primer varies, and the technical scheme adopted is: its processing flow is as follows:

[0046] S1: After coating the base fabric with waterproof agent, drying and setting;

[0047] S2: Prepare an environmentally friendly paint with a fresh marine fragrance, and dry the obtained paint after scraping it on the fabric of S1; wherein the paint includes the following components by weight fraction:

[0048] Pure acrylate soft emulsion: 60-80 parts

[0049] Pure acrylate hard emulsion: 8-12 parts

[0050] Water: 130-150 parts

[0051] Fresh Ocean Microencapsulated Fragrance: 1 serving

[0052] Thickener: 0.1-0.2 parts

[0053] S3: The wall covering obtained in the above step S2 is coated with an intermediate layer and a surface layer to obtain a wall covering.

Embodiment 3

[0055] The difference between this embodiment and Example 1 is that the primer composition changes, and the technical solution adopted is: its processing flow is as follows:

[0056] S1: After coating the base fabric with waterproof agent, drying and setting;

[0057] S2: Prepare an environmentally friendly paint with a fresh marine fragrance, and dry the obtained paint after scraping it on the fabric of S1; wherein the paint includes the following components by weight fraction:

[0058] Pure acrylate soft emulsion: 30-40 parts

[0059] Pure acrylate hard emulsion: 4-6 parts

[0060] Water: 65-75 parts

[0061] Rose microcapsule essence: 1 part

[0062] Thickener: 0.1-0.2 parts

[0063] S3: The wall covering obtained in the above step S2 is coated with an intermediate layer and a surface layer to obtain a wall covering.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com