Jacking self-locking hydraulic cylinder

A hydraulic cylinder and self-locking technology, which is applied in the field of hydraulic cylinders, can solve problems such as internal leakage of hydraulic cylinders and hydraulic locks, hydraulic cylinder piston rods are not easy to be locked, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

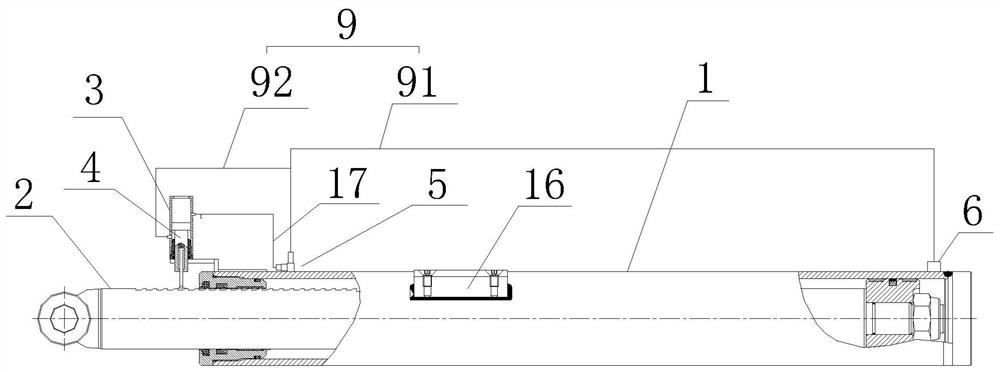

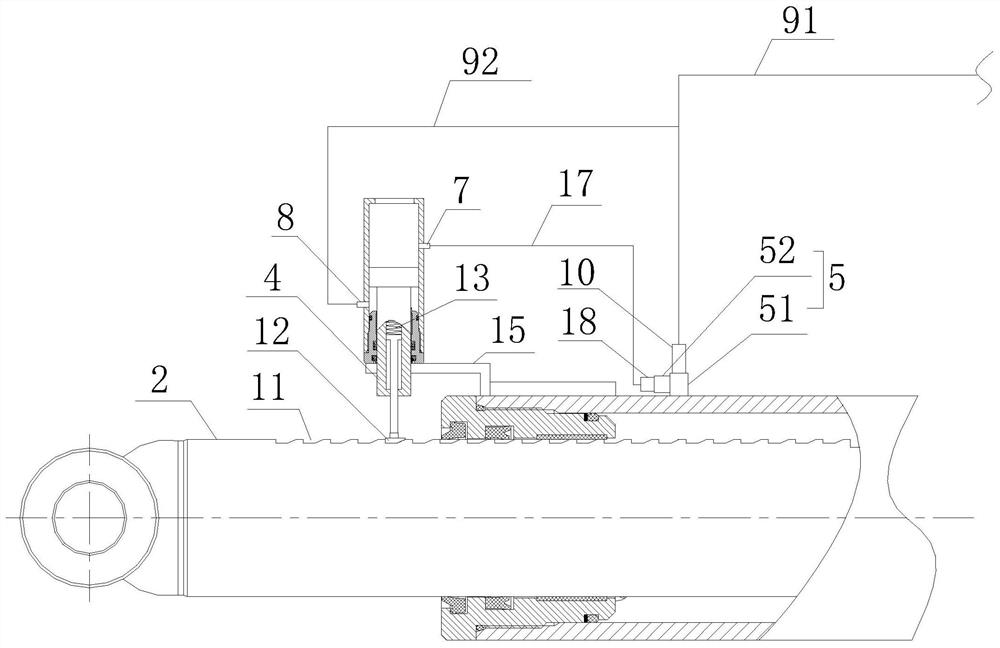

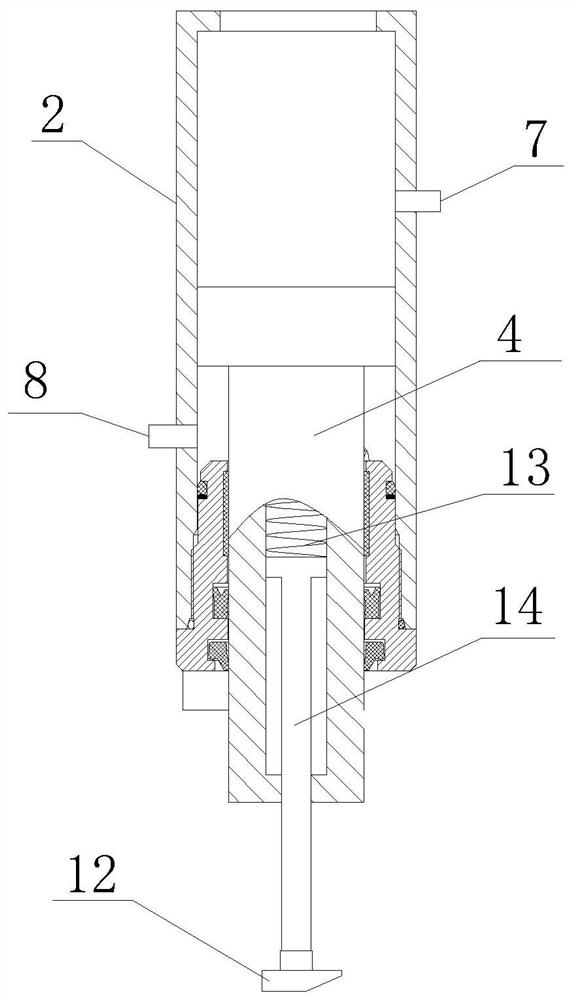

[0023] refer to Figure 1-3 , a jacking self-locking hydraulic cylinder proposed by the present invention, comprising: a master cylinder 1 with an oil port A5 and an oil port B6 and a first piston assembly installed in the master cylinder 1, with an oil port C7, The auxiliary cylinder 3 of the oil port D8 and the second piston assembly installed in the auxiliary cylinder 3, as well as the oil passage 9 for delivering hydraulic oil, the first piston assembly includes the first piston assembly located between the oil port A5 and the oil port B A piston and a first piston rod 2 connected with the first piston, the second piston assembly includes a second piston located on the side of the oil port D8 close to the oil port C7 and a second piston rod 4 connected with the second piston, and the first One end of the piston rod 2 is located outside the main cylinder 1 to form a first ejection end, and one end of the second piston rod 4 is located outside the auxiliary cylinder 3 to for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com