A kind of anti-breaking traction rope for small ship loader

A ship loader and anti-fracture technology, used in textiles, papermaking, textile cables, etc., can solve problems such as cargo injury to staff, traction rope breakage, safety accidents, etc., to achieve soft texture, fast curing speed, and ensure safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

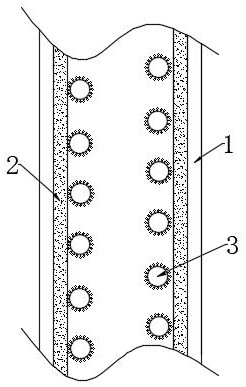

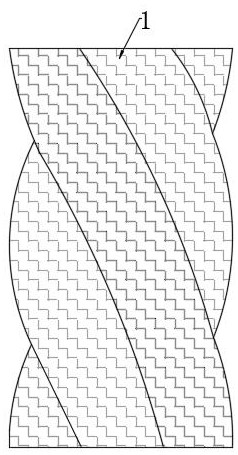

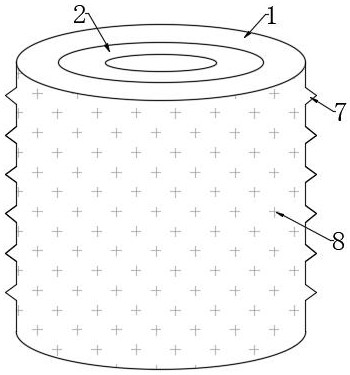

[0034] see figure 1 , a breakage-proof traction rope for a small ship loader, comprising a plurality of braided hoses 1, the inner walls of the braided hoses 1 are evenly provided with magnetic powder 2, and a plurality of repair balls matching the magnetic powder 2 are arranged in the braided hose 1 3. The repair ball 3 is a transparent soft film. Even if the repair ball 3 is not broken, the user can see the red dye inside through the repair ball 3, so as to achieve timely maintenance. Please refer to Figure 4 , the repairing ball 3 is provided with a repairing fluid 4, the repairing fluid 4 is filled with a red dye, and the red dye can flow on the surface of the braided hose 1 after the repairing ball 3 is broken, thereby reminding the user of the breakage of the traction rope in time , and then repair it in time, the repair ball 3 is a transparent soft film, even if the repair ball 3 is not broken, the user can see the red dye inside through the repair ball 3, so as to ach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com