Segment caulking plugging structure and plugging process

A segment and process technology, which is applied in the field of segment caulking sealing structure and plugging process, can solve the problems of groundwater seepage, segment displacement, dislocation, affecting the waterproof effect of caulking, etc., so as to improve the waterproof performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

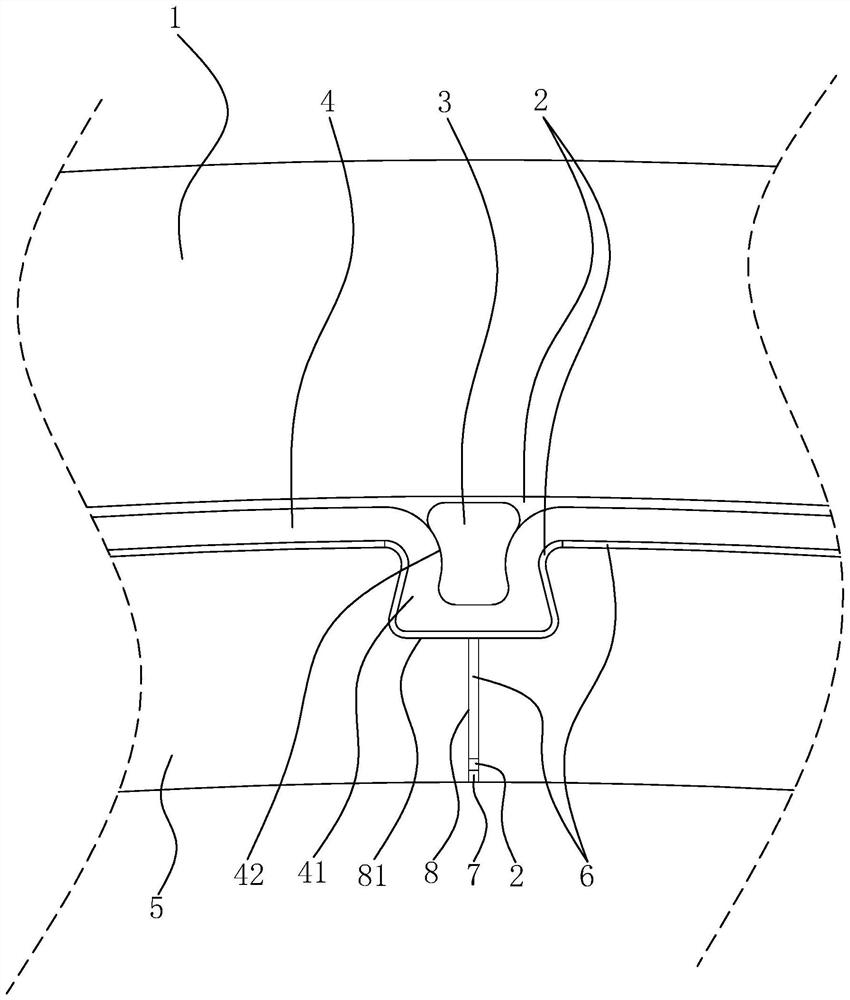

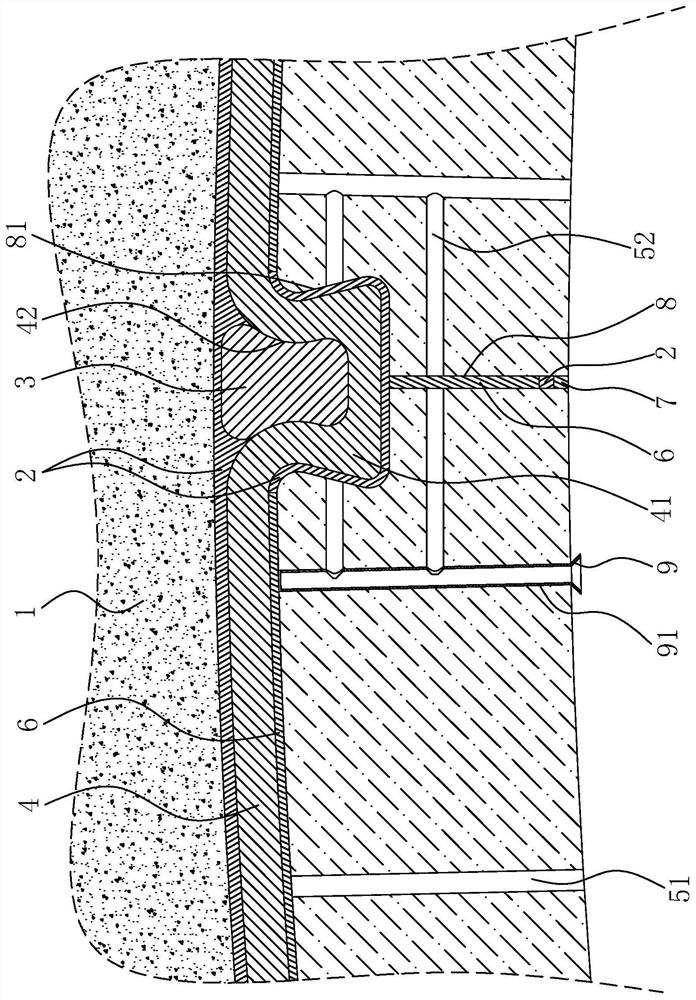

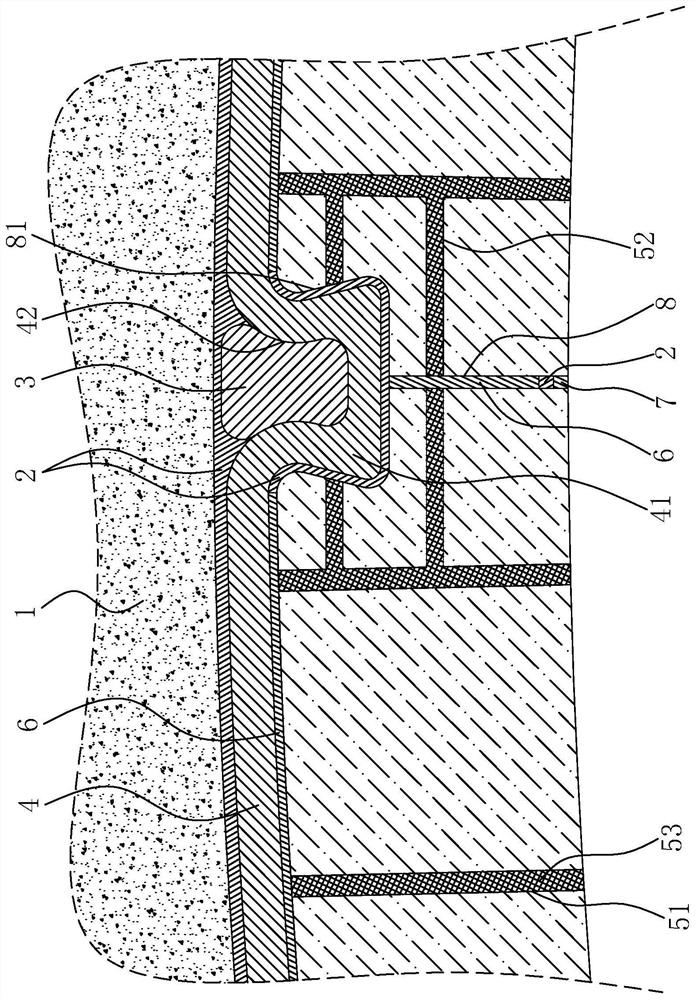

[0040] The following is attached Figure 1-3 The application is described in further detail.

[0041] The embodiment of the present application discloses a segment caulking sealing structure.

[0042] refer to figure 1 and figure 2 The segment caulking sealing structure includes a waterproof rubber strip 4 arranged between the segment 5 and the inner wall 1 of the tunnel, the waterproof rubber strip 4 is located at the caulking 8 between adjacent segments 5, and the waterproof rubber strip 4 is close to the tunnel One side of the inner wall 1 is provided with a water-swellable strip 3 , and the segment 5 is provided with a grouting hole 51 .

[0043] refer to figure 1There is a sealing groove 81 at the end of the caulking 8 close to the inner wall 1 of the tunnel, the length of the sealing groove 81 is the same as that of the caulking 8, and the two sides of the sealing groove 81 are symmetrically set on two adjacent segments 5, sealing The width of the opening of the gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com