Reinforcing method and reinforcing structure for water-rich sand layer geological shield receiving end

A water-rich sand layer and reinforcement structure technology, applied in underground chambers, earthwork drilling, wellbore lining, etc., can solve the problems of high investment cost, uneconomical, and increased shield construction period, etc., to improve the strength of the surrounding soil , Improve the effect of reinforcement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

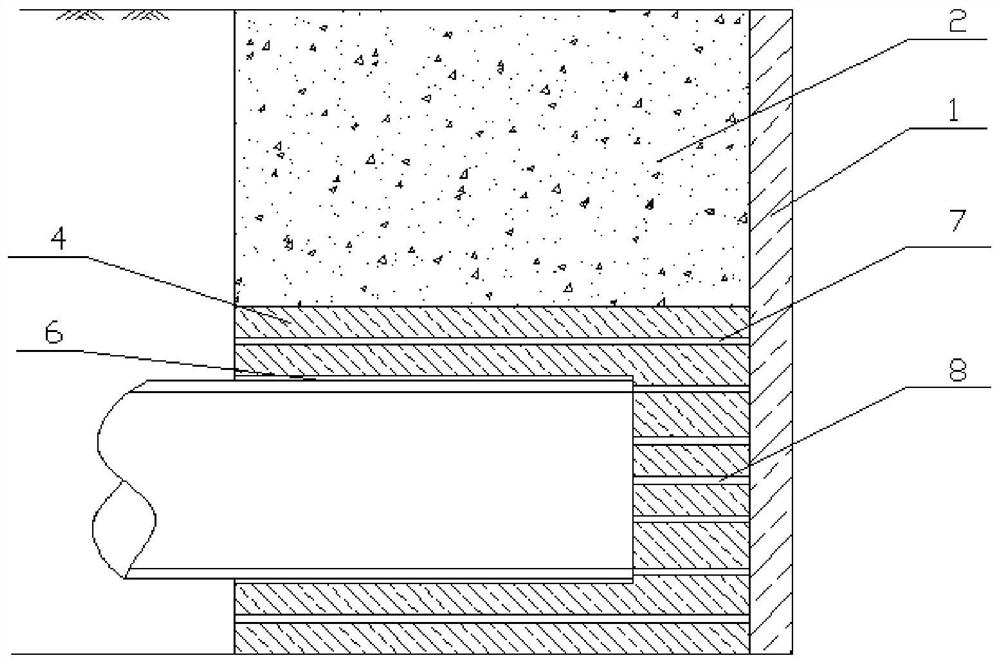

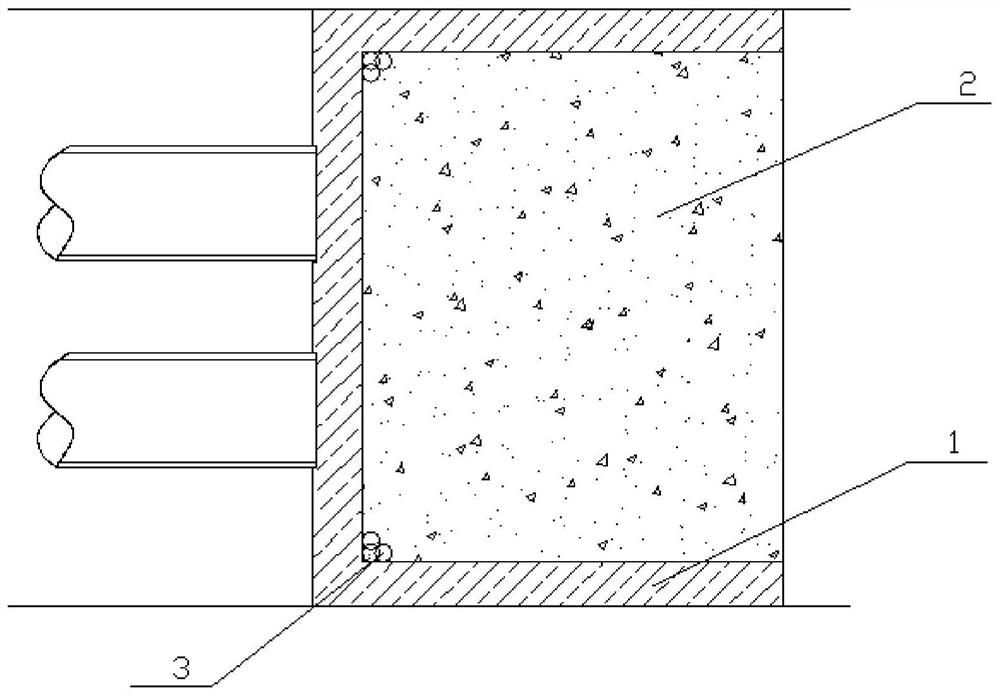

[0040] A method for reinforcing a receiving end of a geological shield in a water-rich sand layer, specifically comprising the following steps:

[0041] (1) Design of the enclosure structure: pouring plain concrete around the receiving end of the shield to form an underground continuous wall with a concave outer structure;

[0042] (2) Layered reinforcement design:

[0043] Implement local freezing design in the depth direction and length direction from the shield tunnel vault 3-5m to the vault bottom 3-5m; carry out the three-axis mixing pile reinforcement design in the depth direction length direction from the ground to the shield tunnel vault 3-5m;

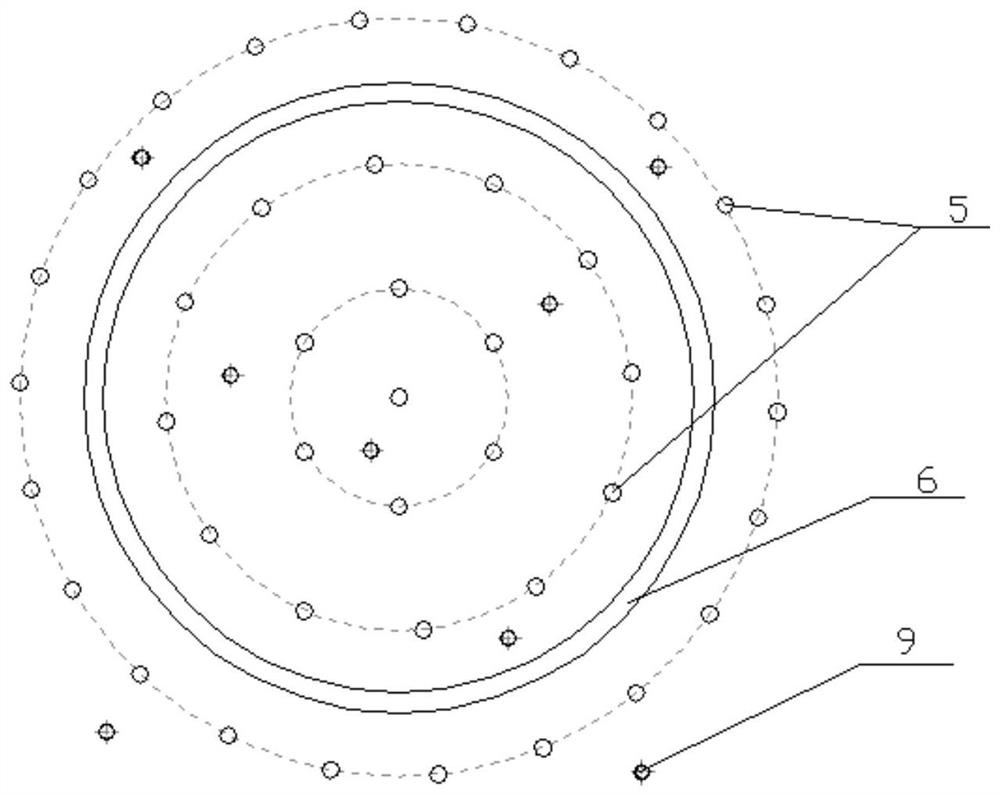

[0044]S1. Freezing design: install a horizontal freezing tube at the receiving end of the shield, the freezing tube is parallel to the advancing direction of the shield, the freezing tube is connected to an external freezing source, and forms a horizontal freezing reinforcement area around the freezing tube;

[0045] The lengt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com