Defrosting control device and defrosting control system of refrigerator

A control device and control system technology, which is applied to household refrigeration devices, cooling fluid circulation devices, defrosting, etc., and can solve the problems of low efficiency of refrigerator defrosting control, waste of energy, and poor defrosting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

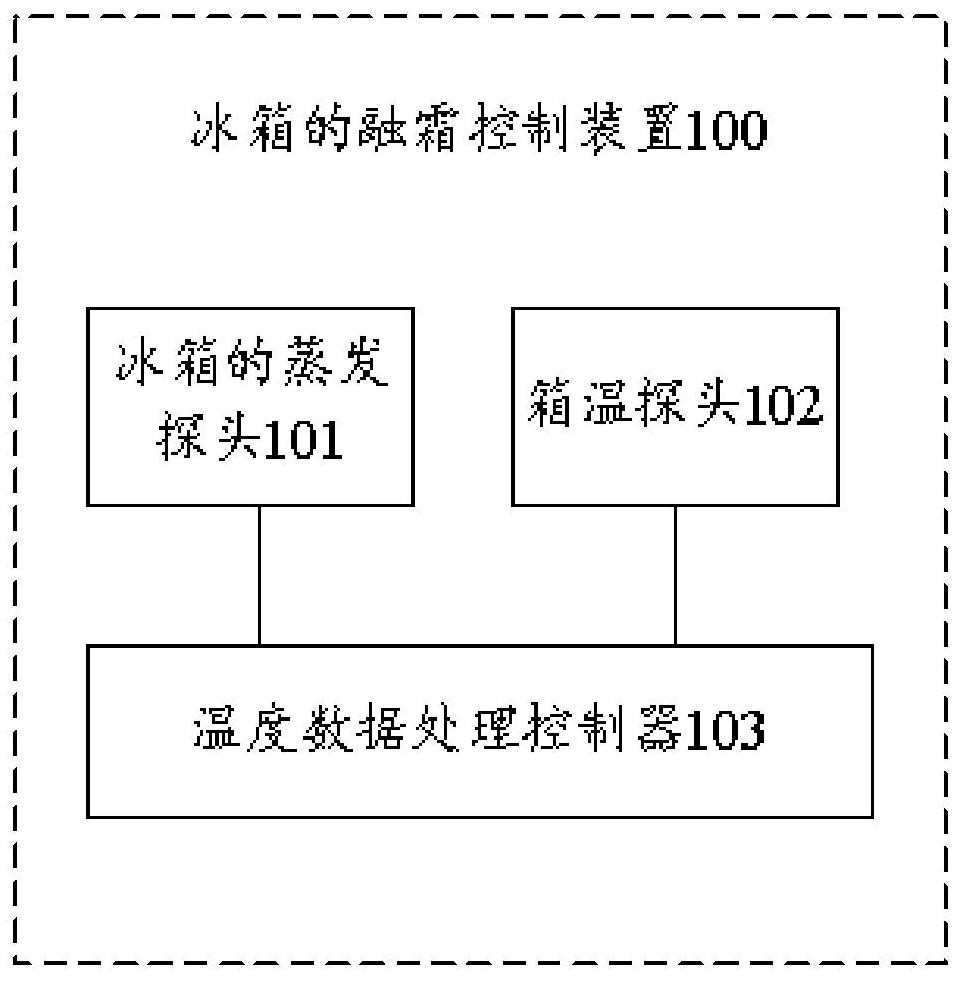

[0035] figure 1 It is a schematic structural diagram of a defrosting control device for a refrigerator provided in an embodiment of the present application. Such as figure 1 As shown, the defrosting control device 100 of the refrigerator includes: an evaporation probe 101 of the refrigerator, a cabinet temperature probe 102 and a temperature data processing controller 103 .

[0036] Among them, the temperature data processing controller is connected with the box temperature probe and the evaporation probe respectively; the box temperature probe is used to detect the cabinet storage temperature of the refrigerator, and transmits the cabinet storage temperature to the temperature data processing controller; the evaporation probe is used to detect the evaporation temperature, and transmit the evaporating temperature to the temperature data processing controller; the temperature data processing controller is used when the refrigerator is in the cooling working phase, when the tem...

Embodiment 2

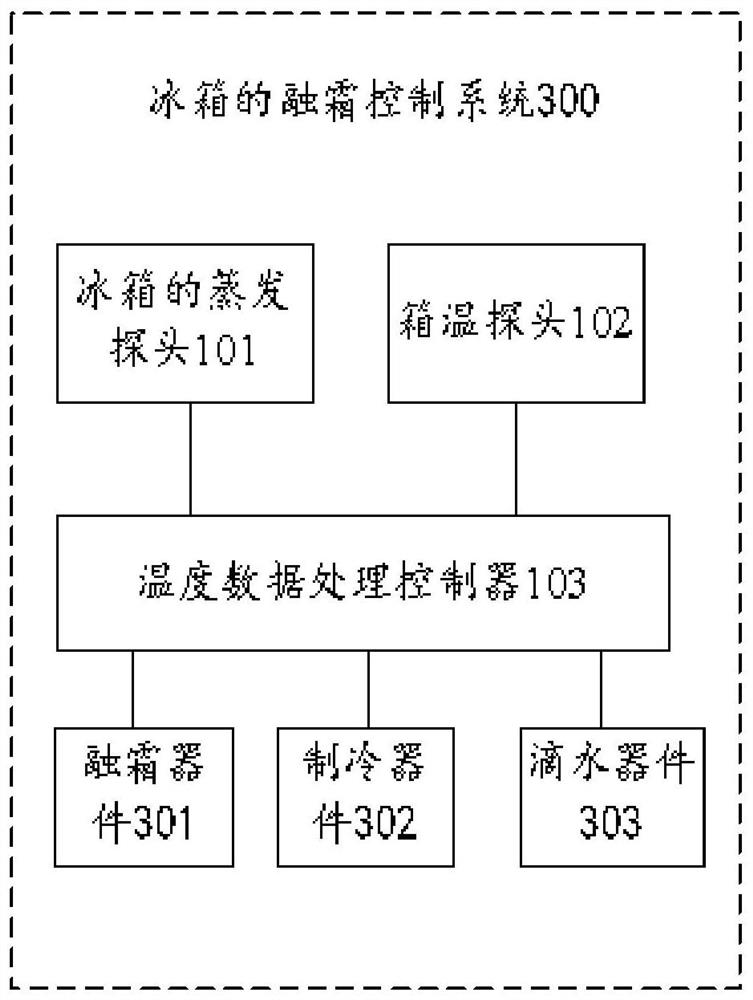

[0049] image 3 It is a schematic structural diagram of a defrosting control system for a refrigerator provided in an embodiment of the present application. Such as image 3 As shown, the defrosting control system 300 of the refrigerator includes: a defrosting device 301, a cooling device 302, a dripping device 303, and the defrosting control device of the refrigerator as provided in the first embodiment above; the temperature data processing in the defrosting control device of the refrigerator The controller is respectively connected with the defrosting device, the refrigeration device and the dripping device.

[0050] In some embodiments, the temperature data processing controller is used to: turn off the cooling device and turn on the defrosting device when the refrigerator exits the cooling working phase and enters the defrosting working phase. That is, the temperature data processing controller includes the functions of controlling the cooling and defrosting components....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com