A kind of HDI board drilling depth detection equipment and detection method

A technology for detecting equipment and drilling depth, which is applied in the field of HDI board drilling depth detection equipment, and can solve problems such as increasing the work intensity of workers, making reading errors, and difficult to read scale sizes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

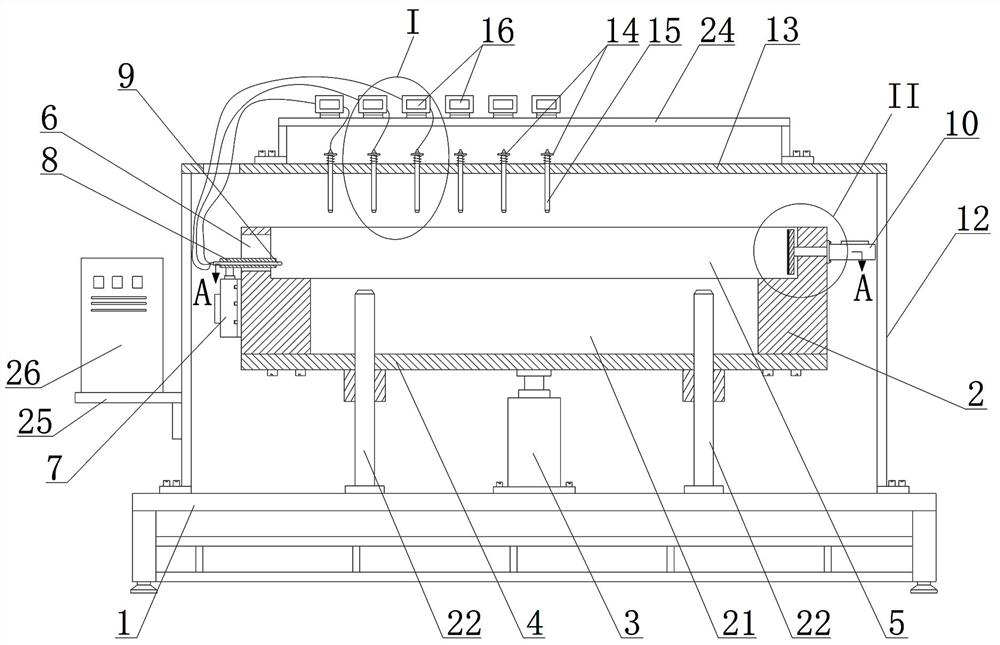

[0032] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

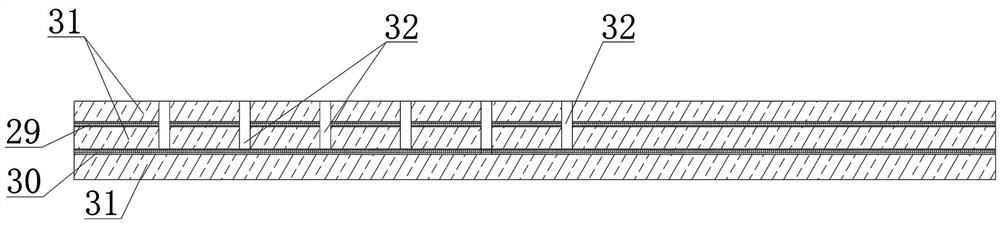

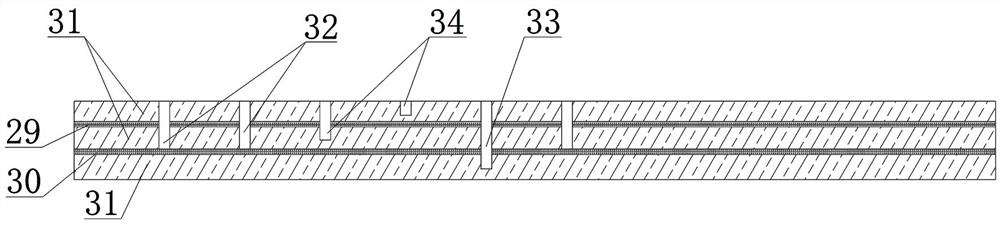

[0033] Such as Figure 3~Figure 8As shown, a HDI board drilling depth detection equipment, it includes a workbench 1 and a positioning seat 2, a lift cylinder 3 is fixed on the table of the workbench 1, and a lifting cylinder 3 is fixed on the active end of the piston rod of the lift cylinder 3. The lifting plate 4, the positioning seat 2 is fixed on the top surface of the lifting plate 4, the positioning seat 2 and the lifting plate 4 are made of plastic, the top surface of the positioning seat 2 is provided with a sinking groove 5, and the horizontal direction of the sinking groove 5 Width is less than the transverse width of the HDI board to be detected, and the longitudinal width of sinker 5 is equal to the longitudinal width of HDI board, and the left side wall of described locating seat 2 is pr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap