Arc extinguish chamber and tank-type circuit breaker

A static arc contact and moving contact technology, applied in circuit breaker parts, circuit breaker contacts, etc., to achieve the effect of being conducive to miniaturization, miniaturization, and reducing radial dimensions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

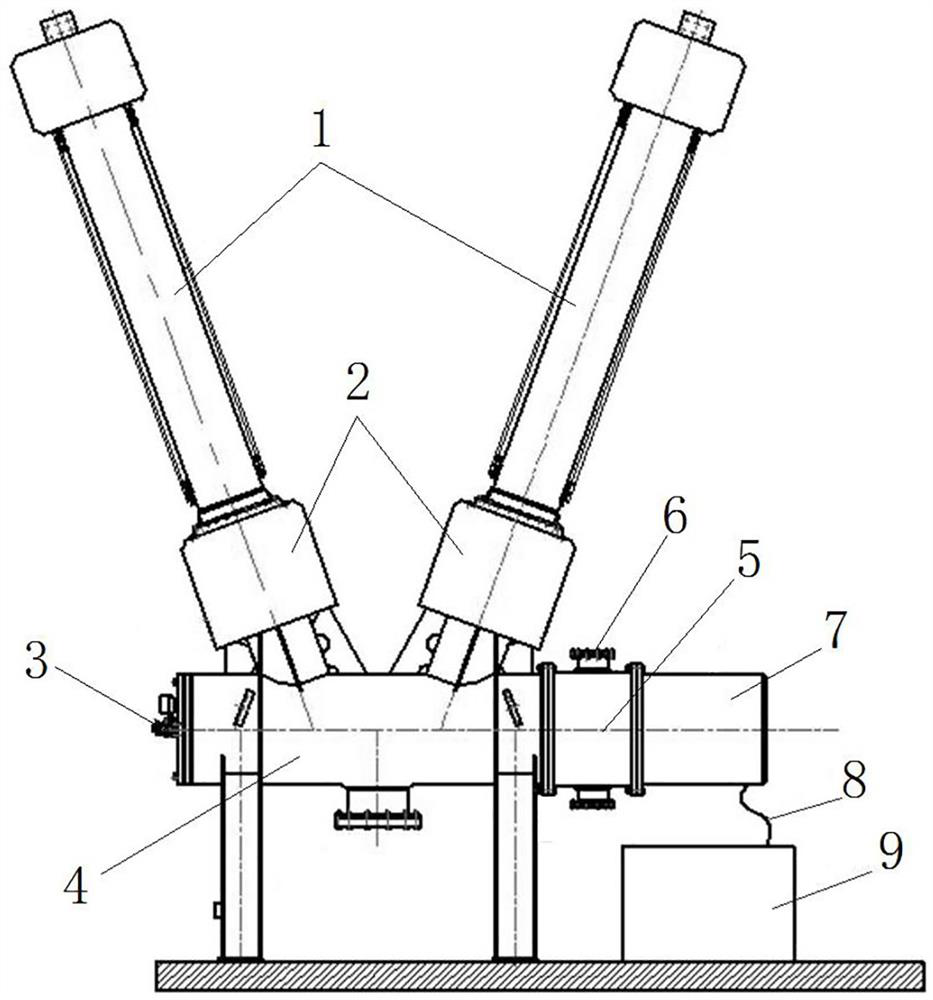

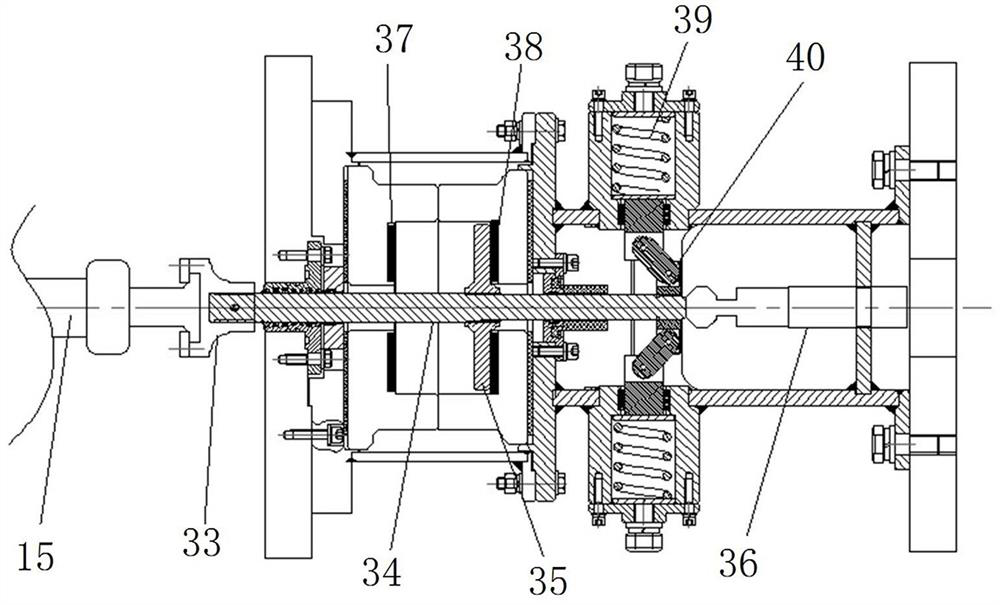

[0046]Such as figure 1 As shown, the tank type circuit breaker includes an arc extinguishing chamber 4, a transition cylinder 5 and a repulsion mechanism 7 arranged in sequence from left to right. The lower end of the bushing 1 is equipped with a current transformer 2, the current enters and exits the arc extinguishing chamber 4 through the inlet and outlet bushing 1, and the current transformer 2 is used to monitor the line current; the left flange of the arc extinguishing chamber 4 is provided with a density meter 3 , the density meter 3 is used to detect the insulating gas density in the arc extinguishing chamber 4; the repulsion mechanism 7 is connected to the power box 9 through a cable 8. Wherein, the repulsion mechanism 7 constitutes a driving mechanism; the power supply box 9 is designed in a separate form, and the arrangement is flexible.

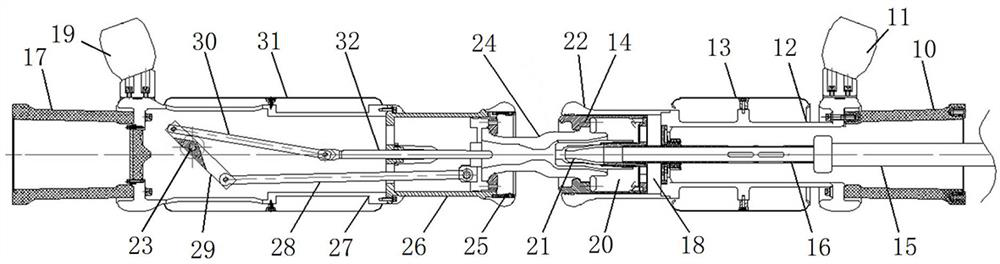

[0047] Such as figure 2 As shown, the arc extinguishing chamber 4 includes a casing, and a moving contact assembly and a stati...

Embodiment 2

[0061] The difference between this embodiment and Embodiment 1 is that in Embodiment 1, when the rotating plate 29 is perpendicular to the static arc contact 32 , the center point of the rotating plate is on the reference plane. In this embodiment, when the rotating arm is perpendicular to the static arc contact, the center point of the rotating arm and the rotating axis of the rotating shaft are at same side of the reference plane. In other embodiments, when the rotating arm is perpendicular to the static arc contact, under the condition that the rotating axis of the rotating shaft and the hinge axis of the fourth hinged shaft are on the same side of the reference plane, the center point of the rotating arm is in the on both sides of the reference plane.

Embodiment 3

[0063] The difference between this embodiment and Embodiment 1 is that in Embodiment 1, the rotating arm is a rotating plate 29 . In this embodiment, the rotating arm is a rotating rod.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com