Combined ladder type cable bridge with adjustable wiring assembly

A cable tray, adjustable technology, applied in the direction of electrical components, etc., can solve the problems of easy leakage, exposed copper wires, inconvenient installation and maintenance, etc., to achieve the effect of improving clarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

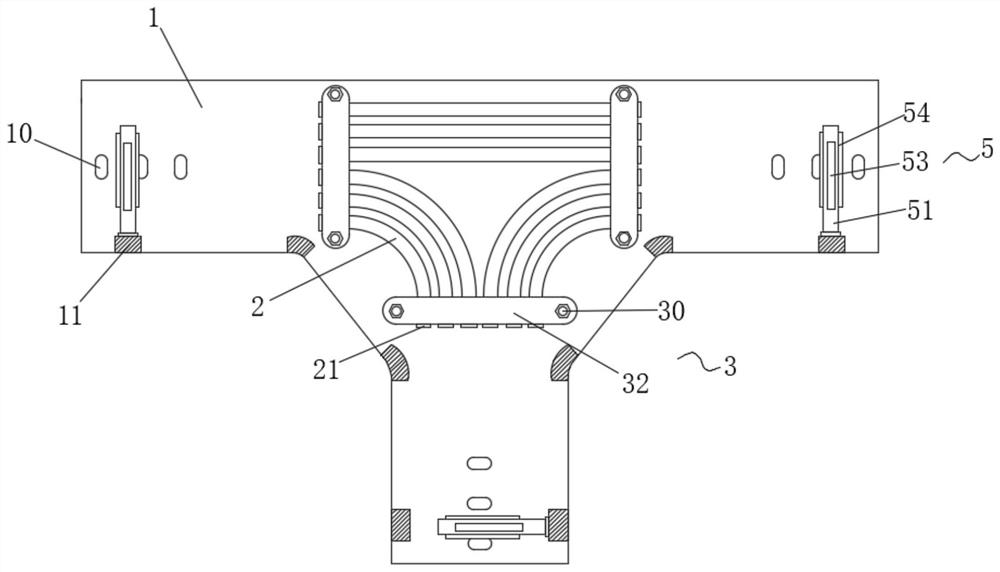

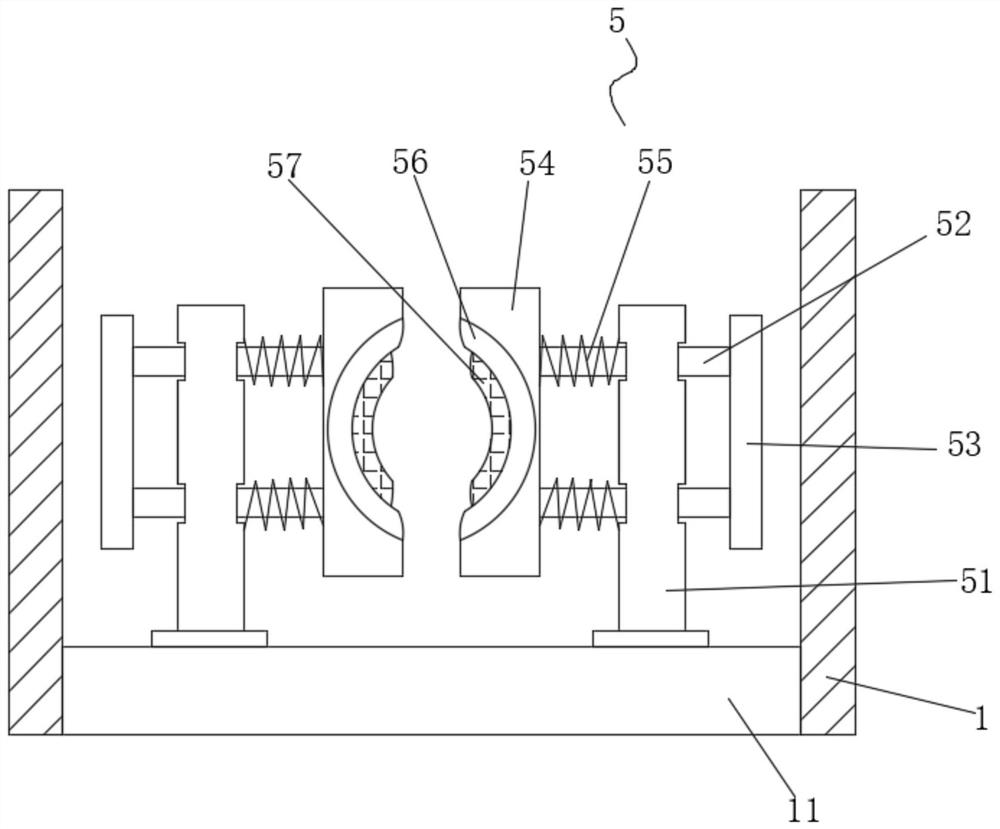

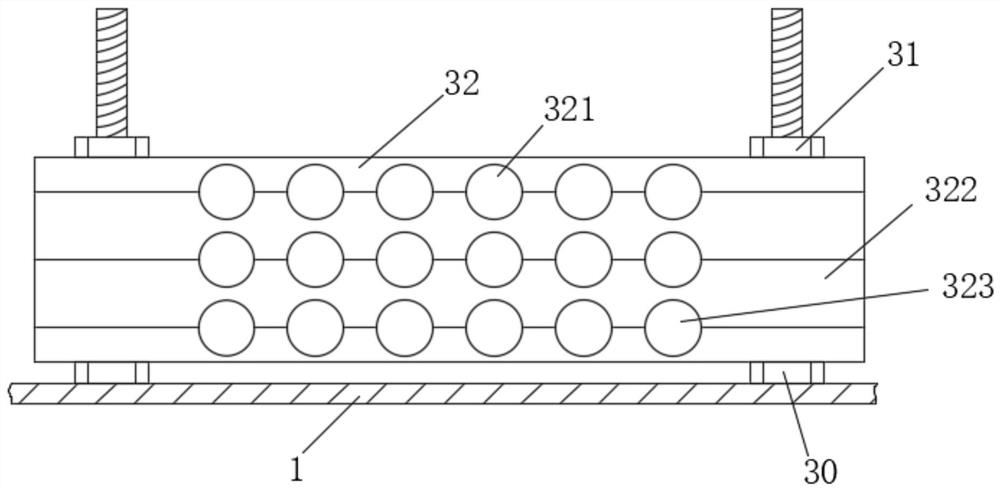

[0032] see figure 1 As shown, the present invention is a combined ladder-type cable tray equipped with adjustable wiring components, including symmetrically arranged "T"-shaped frame walls 1, and the bridge is mainly used to solve the problem of cables in traditional bridges when connecting wiring. There are problems such as confusion of cable harnesses and troublesome separation when turning. There are several connecting frames 11 symmetrically arranged between the two frame walls 1, wherein, in the horizontal direction of the frame walls 1, the connecting frames 11 are arranged at the lower edge of the frame wall 1. In the vertical direction of the frame wall 1, the connecting frame 11 is symmetrically arranged on both sides, and a number of turning assemblies 3 are arranged on the side of one frame wall 1 between the two frame walls 1, and a number of steering pipes are connected between the turning assemblies 3 2. The connecting frame 11 located at the end of the two frame...

Embodiment 2

[0038] see figure 1As shown, the present invention is a combined ladder-type cable tray equipped with adjustable wiring components, including symmetrically arranged "T"-shaped frame walls 1, and the bridge is mainly used to solve the problem of cables in traditional bridges when connecting wiring. There are problems such as confusion of cable harnesses and troublesome separation when turning. There are several connecting frames 11 symmetrically arranged between the two frame walls 1, wherein, in the horizontal direction of the frame walls 1, the connecting frames 11 are arranged at the lower edge of the frame wall 1. In the vertical direction of the frame wall 1, the connecting frame 11 is symmetrically arranged on both sides, and a number of turning assemblies 3 are arranged on the side of one frame wall 1 between the two frame walls 1, and a number of steering pipes are connected between the turning assemblies 3 2. The connecting frame 11 located at the end of the two frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com