Cutting type flocking equipment for flocking carpet for ocean engineering

A marine engineering and flocking technology, which is applied to the surface coating device, coating, etc., can solve the problems of easy fluff falling off, uneven flocking, and less fluff on the surface of the steel plate, so as to avoid rolling and pilling , fluffy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

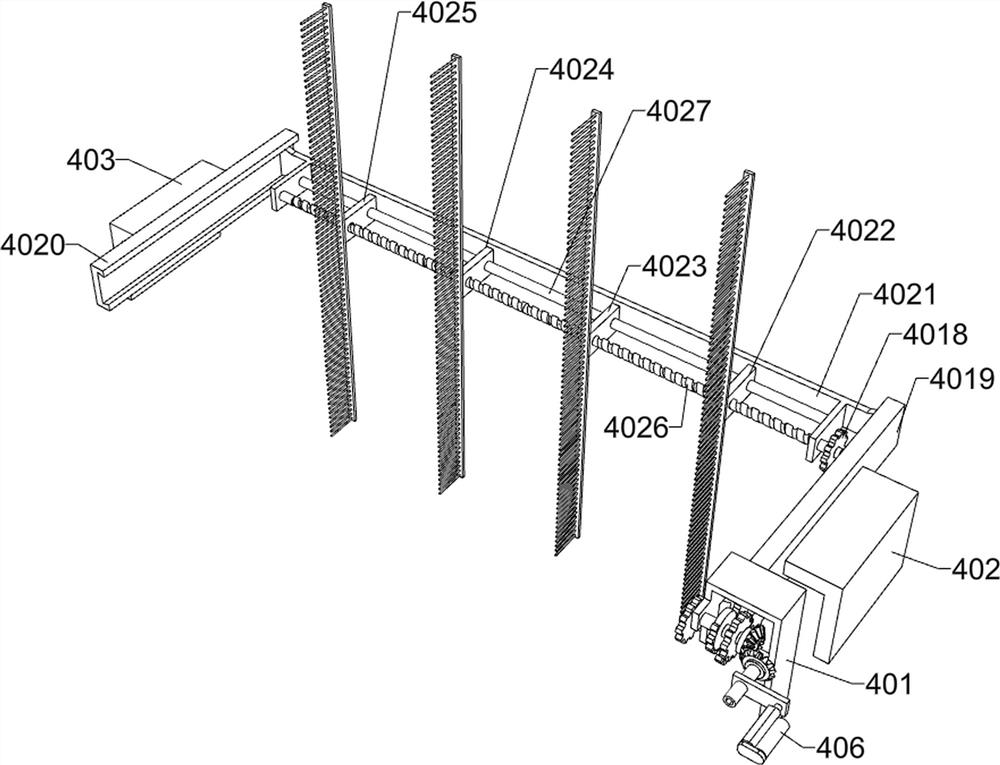

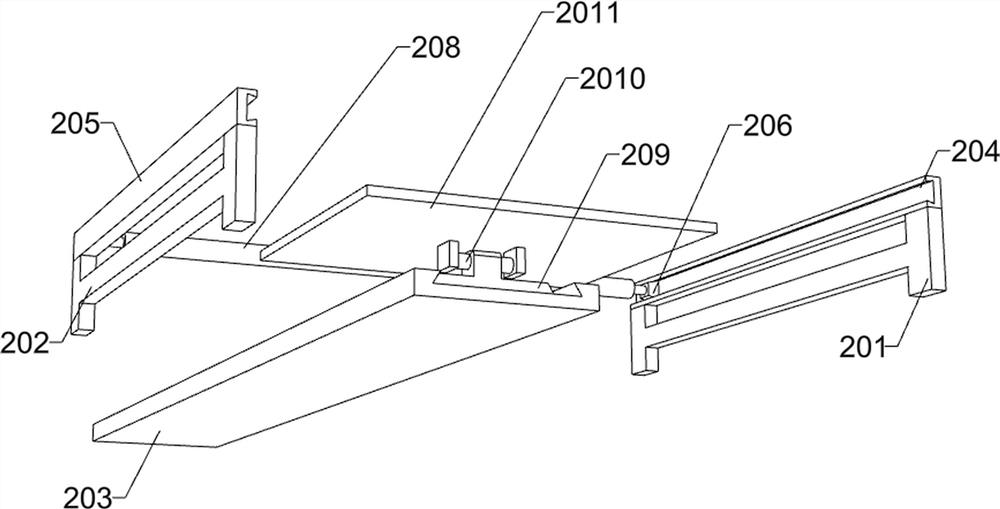

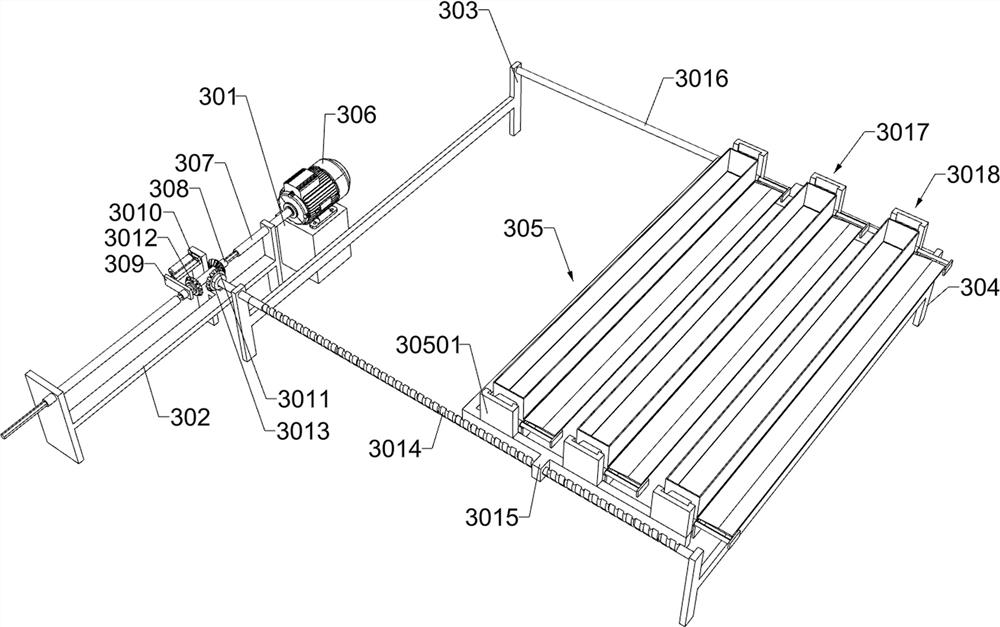

[0034] A cutting-type flocking carpet flocking equipment for marine engineering, refer to Figure 1-3 As shown, it includes a chassis 1, a first support 2, a first support 3, a second support 4, a third support 5, a fourth support 6, a control panel 7, a collection box 8, a transmission unit, a plant Down unit and bristle unit; underframe 1 is fixedly connected with first support 2; underframe 1 is fixedly connected with first support 3; underframe 1 is fixedly connected with second support 4; underframe 1 is fixedly connected with third support The support 5 is fixed; the bottom frame 1 is fixed with the fourth support 6; the bottom frame 1 is fixed with the collection box 8; the bottom frame 1 is fixed with the transmission unit; the bottom frame 1 is fixed with the flocking unit. connection; the flocking unit implants the fluff on the surface of the steel plate; 1. the bottom frame is fixedly connected with the bristle unit; the side of the flocking unit is connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com