Forging die for rotary forging of forging steel brake disc of high-speed train

A technology for high-speed trains and brake discs, which is applied in the direction of manufacturing tools, forging/pressing/hammering machinery, casting molding equipment, etc., and can solve the problems of incomplete filling of gaps, reduced ductility, and increased placement distance , to achieve the effect of avoiding incomplete filling and avoiding curling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

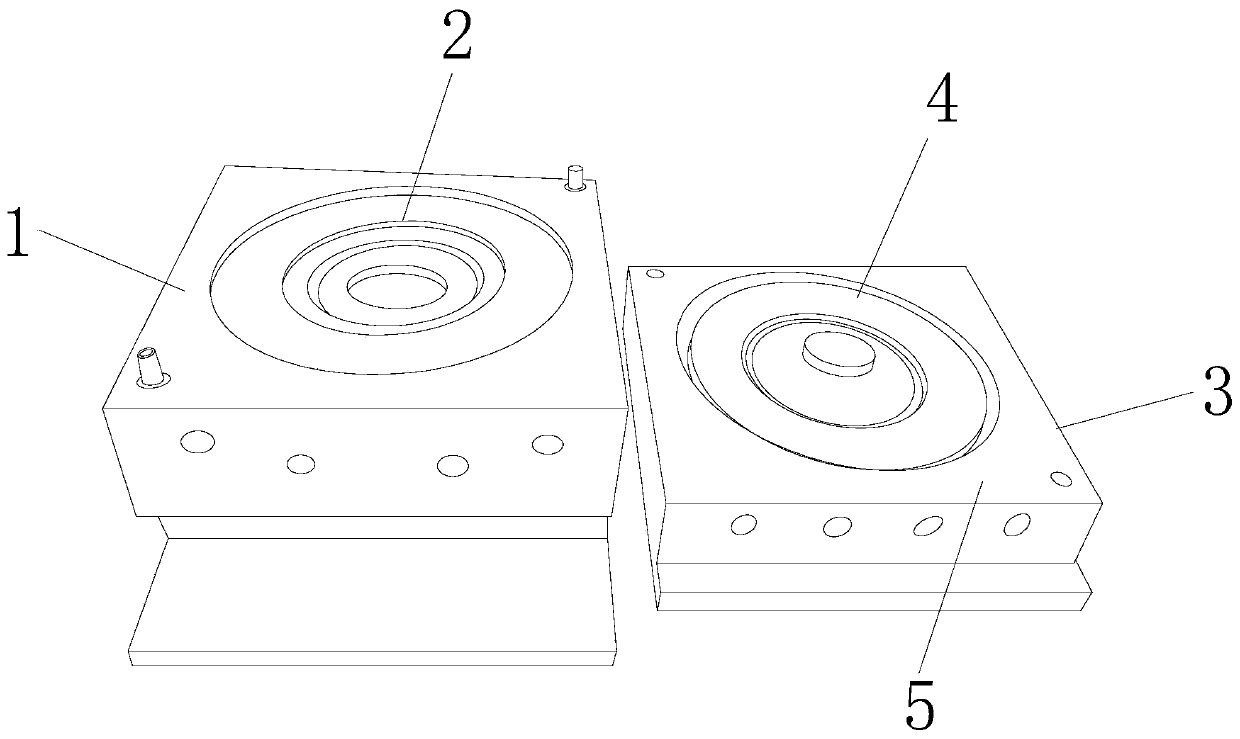

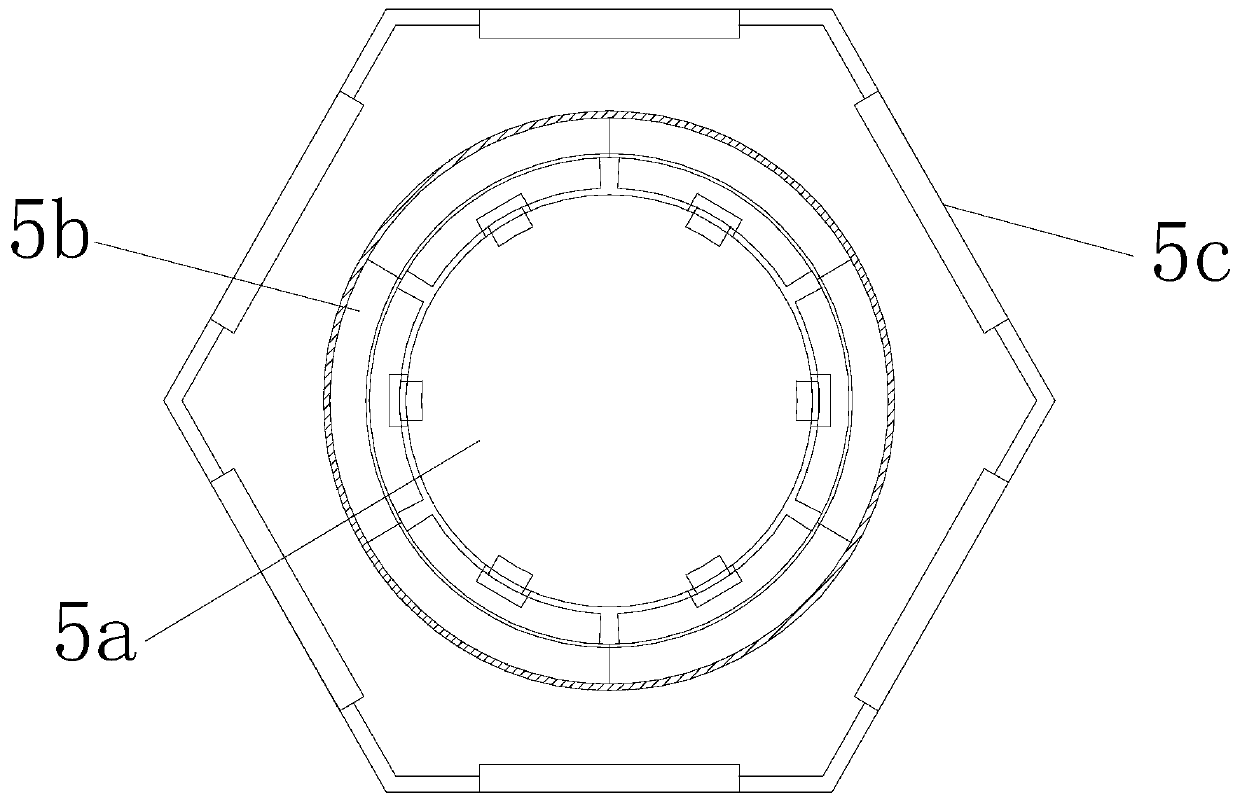

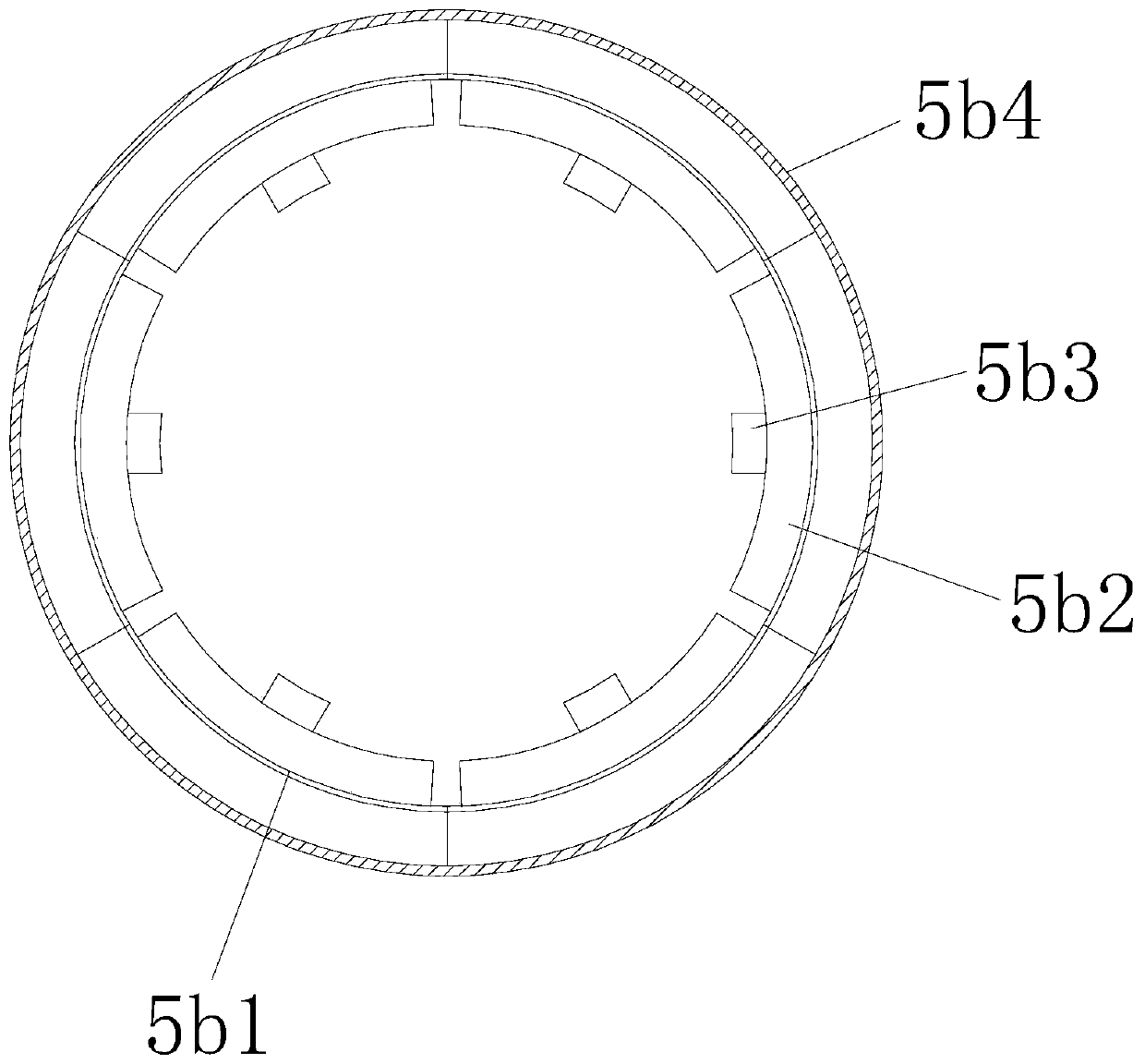

[0030] Such as Figure 1-Figure 5 As shown, the present invention provides a kind of technical scheme for the forging die of the high-speed train forged steel brake disc swing roller:

[0031] Such as Figure 1-Figure 2 Shown, a kind of forging mold that is used for high-speed train forged steel brake disc swinging, its structure comprises lower mold 1, swinging cavity 2, upper mold 3, punch 4, ring filling device 5, described swinging cavity 2 is set in the middle of the surface of the lower mold 1 and is an integrated structure, the upper mold 3 is fastened with the lower mold 1, the punch 4 is set in the middle of the lower surface of the upper mold 3 and connected by electric welding, the ring filling The device 5 is set inside the upper mold 3 and connected by electric welding. The ring filling device 5 includes a buckle shaft 5a, a sound transmission mechanism 5b, and an anti-rolling structure 5c. The buckle shaft 5a is set in the middle of the sound transmission mechan...

no. 2 example

[0043] Such as figure 1 , figure 2 , Figure 6 As shown, the present invention provides a kind of technical scheme for the forging die of the high-speed train forged steel brake disc swing roller:

[0044] Such as Figure 1-Figure 2 Shown, a kind of forging mold that is used for high-speed train forged steel brake disc swinging, its structure comprises lower mold 1, swinging cavity 2, upper mold 3, punch 4, ring filling device 5, described swinging cavity 2 is set in the middle of the surface of the lower mold 1 and is an integrated structure, the upper mold 3 is fastened with the lower mold 1, the punch 4 is set in the middle of the lower surface of the upper mold 3 and connected by electric welding, the ring filling The device 5 is set inside the upper mold 3 and connected by electric welding. The ring filling device 5 includes a buckle shaft 5a, a sound transmission mechanism 5b, and an anti-rolling structure 5c. The buckle shaft 5a is set in the middle of the sound tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com