Pipeline welding seam interlayer temperature control device

A technology of interlayer temperature and control device, which is applied in welding equipment, manufacturing tools, arc welding equipment, etc., can solve problems such as the need to control interlayer temperature, so as to avoid serious grain coarsening, hardened structure and influence diffusion Hydrogen escape, the effect of ensuring welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

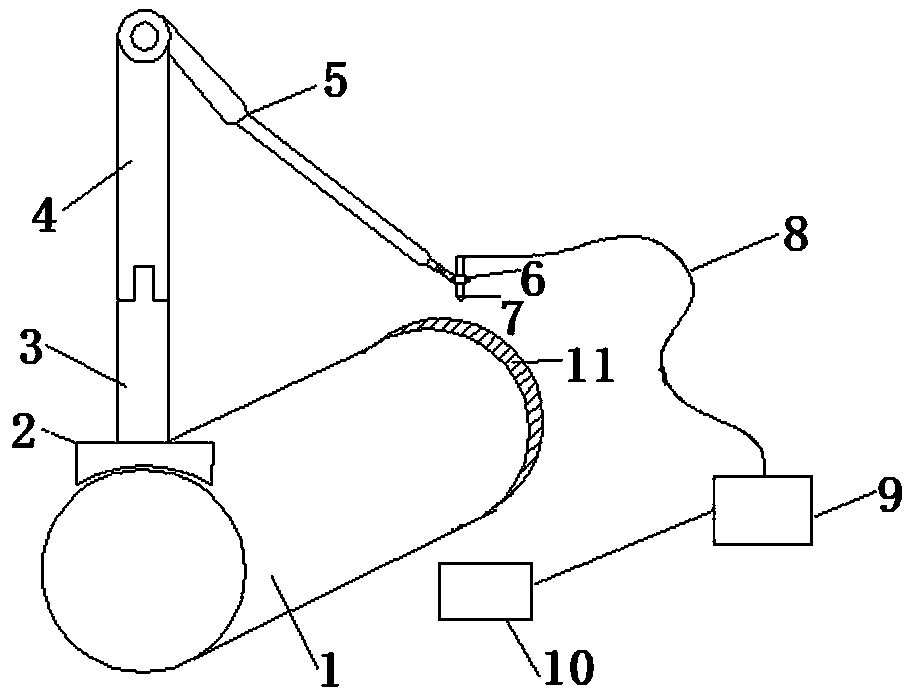

[0017] Attached below figure 1 And the specific examples further describe the present invention in detail.

[0018] like figure 1 The interlayer temperature control device for pipeline welding mainly includes a strong magnet 2 adsorbed on the pipeline 1, a support part 3 fixedly connected to the vertical direction above the strong magnet, and a joint between the axis of the pipeline 1 and the axis of the support part 3. On the formed plane, the rotating part 4 that can rotate 180° along the support part 3, the telescopic adjusting rod 5 that can rotate 360° around the rotating part 4, and the temperature detection device that is fixedly connected to the moving end of the telescopic adjusting rod 5, said The temperature detection device comprises a far-infrared thermometer 7, said far-infrared thermometer 7 is fixedly connected to the movable end of telescopic adjustment rod 5 by fastening bolt 6, and said far-infrared thermometer 7 is connected with a temperature relay by a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com