Method for thinning welding-seam organization and increasing welding-seam ductility during welding the titanium alloy, powder filling device

A welding process, titanium alloy technology, applied in welding/welding/cutting items, welding equipment, welding accessories, etc., can solve problems such as failure to prevent grain growth and plasticity reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

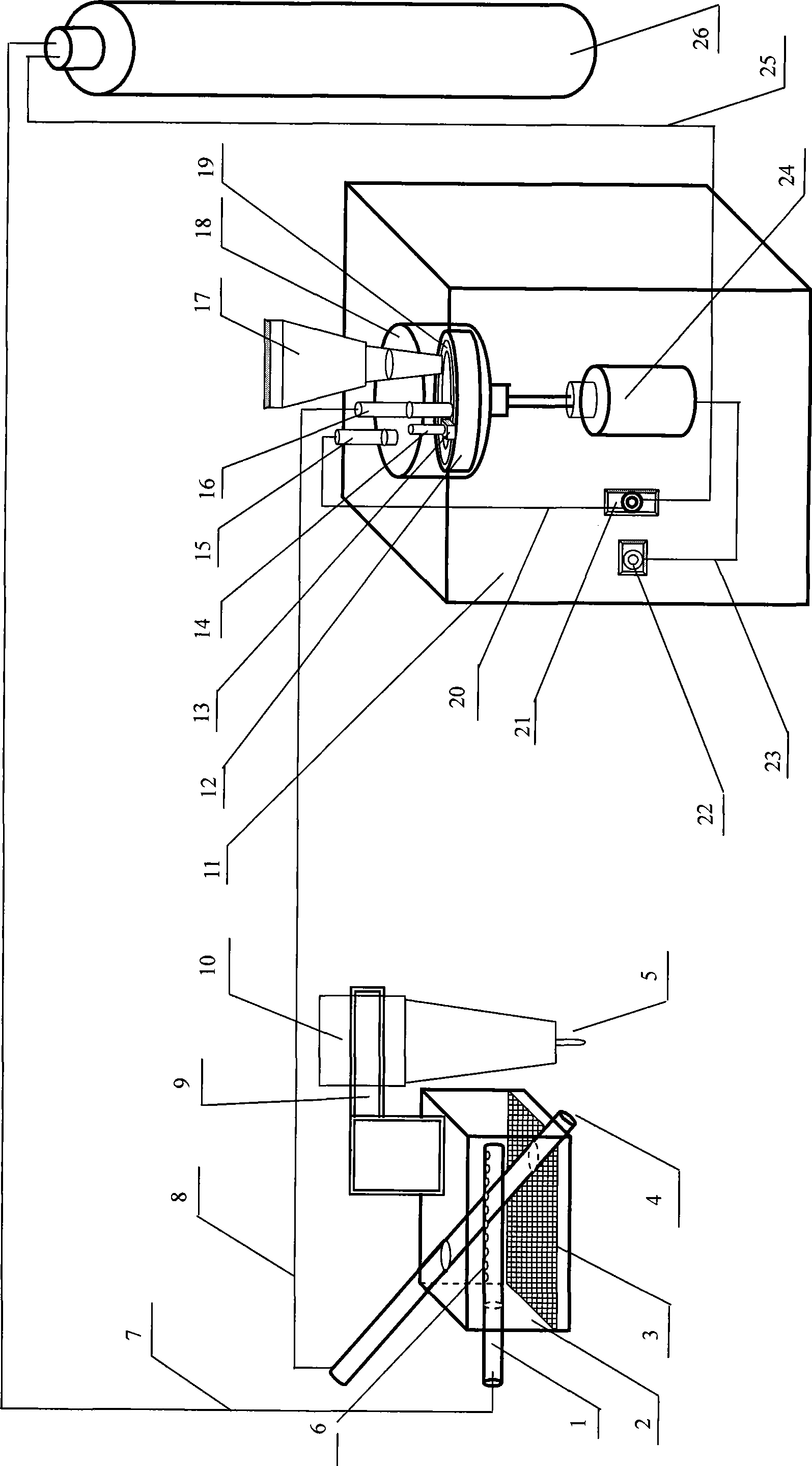

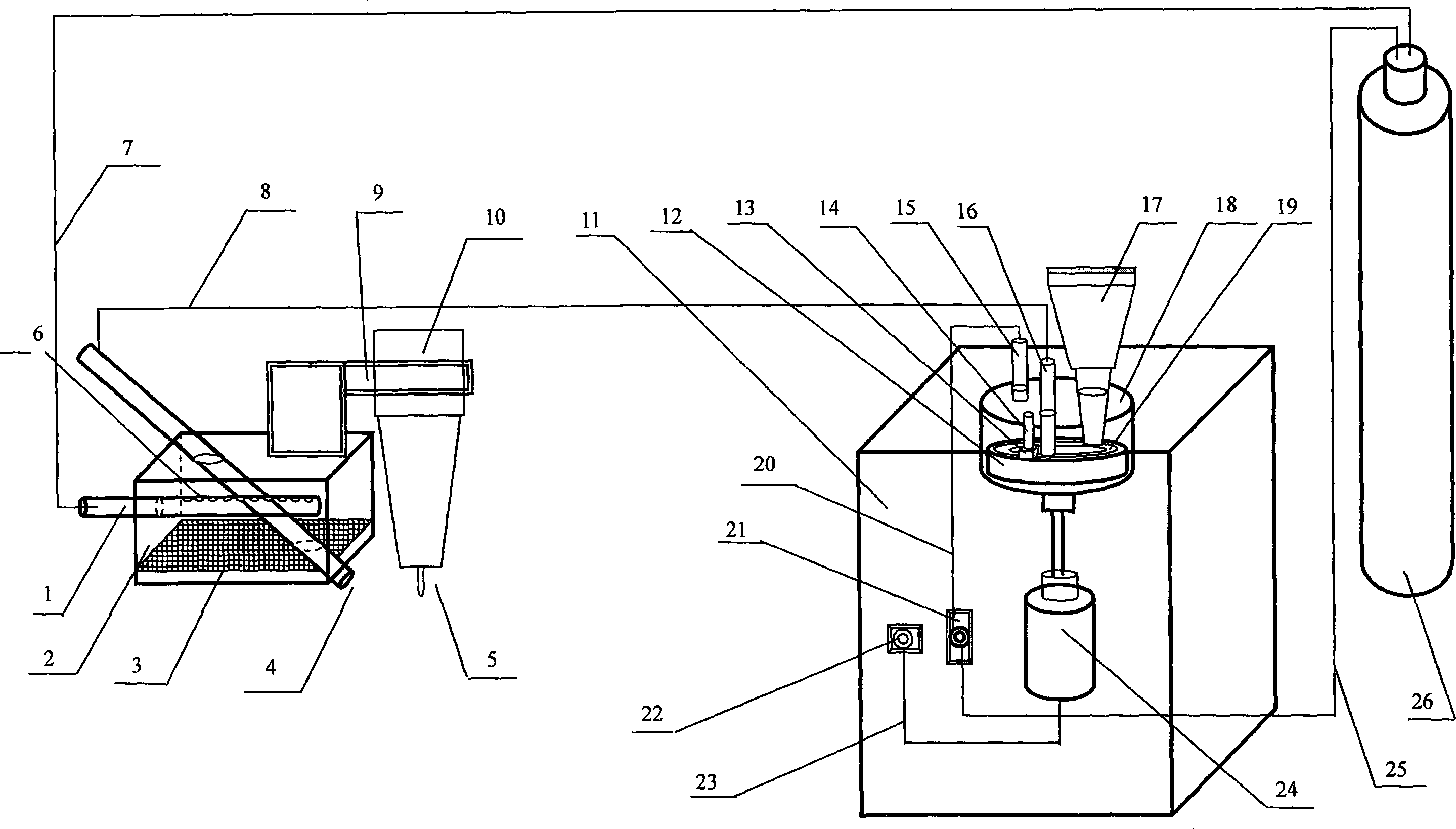

Embodiment 1

[0030] Embodiment 1: During the argon tungsten arc welding process of TA15 titanium alloy, the method of adding TC4 titanium alloy powder along with welding is adopted. TA15 plate thickness is 2.5mm, TC4 powder particle size is -65 mesh to +80 mesh and -60 to +65 mesh, the angle between the powder outlet and the horizontal direction is 30°, the width is 6mm, and the height is 5.5mm. Located 10mm behind the axis of the tungsten pole, the welding speed is 4.3mm / s, the welding current is 170A~190A, the arc voltage is 13.0V~15.0V, the welding method is board surfacing welding, and the back of all test boards is fully penetrated and the back is welded wide Basically the same. After welding, the test plate was annealed at 630°C×1hr, the bending angle of the welded joint was tested, and the number of grains per square millimeter was measured through metallographic analysis of the weld, and the grain size grade was converted. Table 1 is the test conditions and test results. It can b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com