Synthetic resin stent and stent delivery system

A technology of synthetic resin and constituent parts, applied in stents, medical science, prostheses, etc., can solve problems such as inability to exert performance and poor followability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

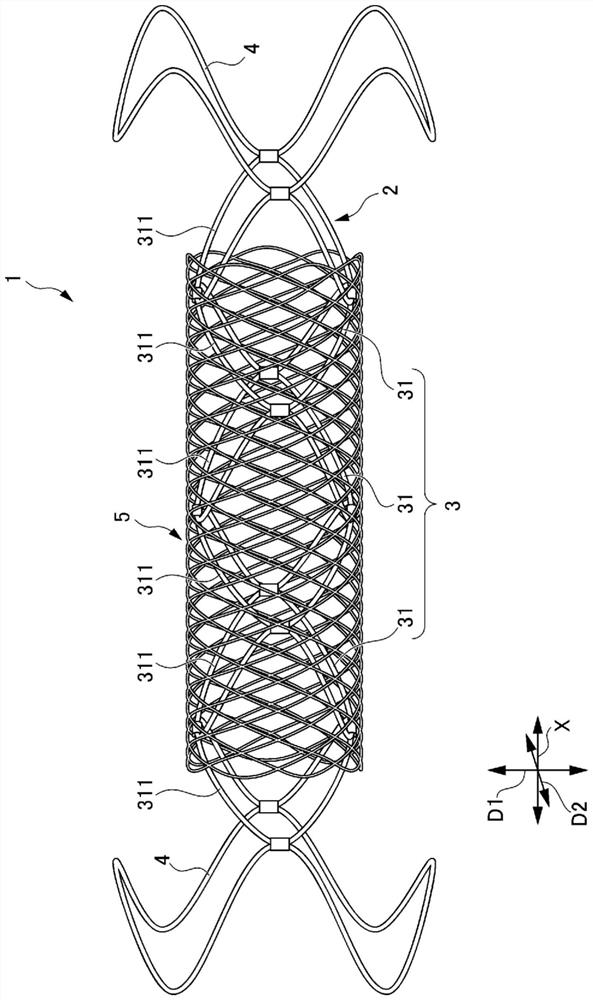

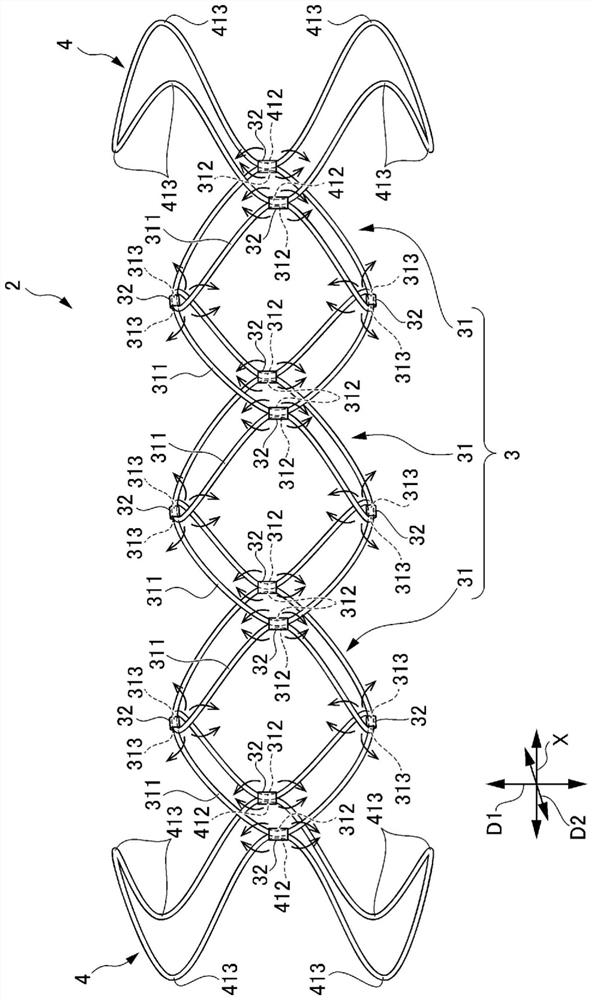

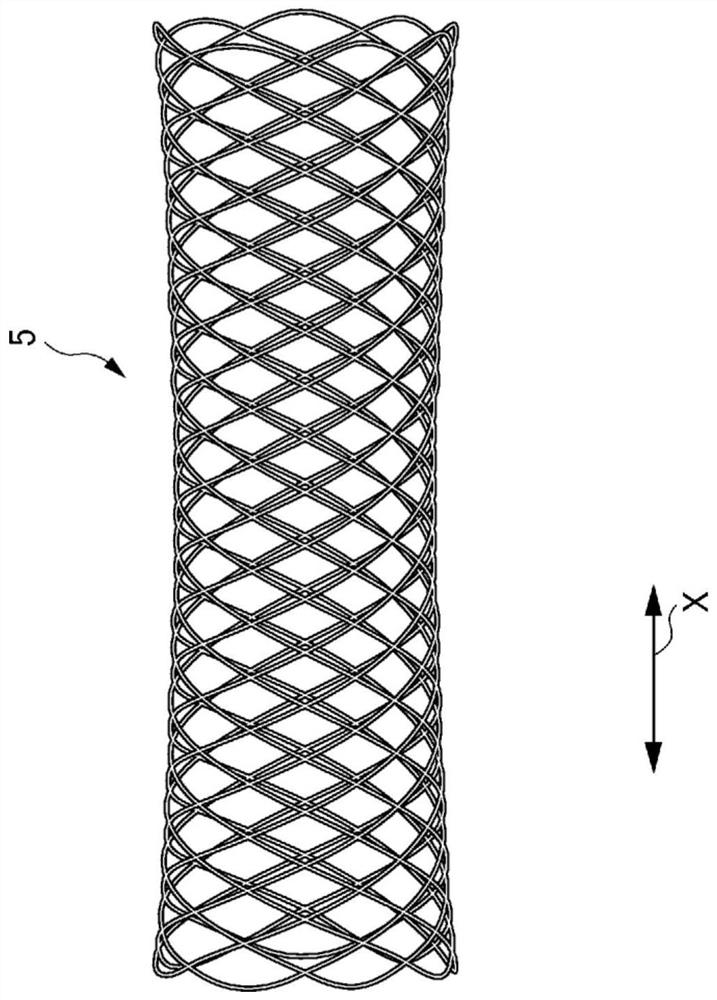

[0048] Hereinafter, a preferred first embodiment of the synthetic resin stent of the present invention will be described with reference to the drawings. figure 1 It is a perspective view showing the biodegradable stent 1 according to the first embodiment of the present invention. figure 2 It is a perspective view showing the inner bracket 2 of the first embodiment. image 3 It is a perspective view showing the outer bracket 5 of the first embodiment. In addition, in the description of this embodiment, the direction in which the biodegradable stent 1 extends as a whole is referred to as the longitudinal direction X, and the direction perpendicular to the longitudinal direction X and figure 1 The up-and-down direction in is called the first direction D1, and the direction perpendicular to the longitudinal direction X and the first direction D1 is called the second direction D2.

[0049] The synthetic resin stent of this embodiment is a biodegradable stent 1 made of biodegrada...

no. 2 approach

[0098] Next, a second embodiment of the present invention will be described. Figure 4 It is a perspective view showing the biodegradable stent 10 of the second embodiment. The biodegradable stent 10 of the second embodiment mainly differs in the structures of the inner stent 6 and the outer stent 11 .

[0099] The synthetic resin scaffold of the second embodiment is a biodegradable scaffold 10 made of biodegradable fibers, such as Figure 4 As shown, an inner frame 6 (first frame) and an outer frame 11 (second frame) disposed outside the inner frame 6 are provided. A central portion of the inner bracket 6 in the longitudinal direction X (axial direction) is disposed inside the outer bracket 11 . In the second embodiment, descriptions of the configurations described in the first embodiment are omitted.

[0100] Like the biodegradable stent 1 of the first embodiment, the biodegradable stent 10 of the second embodiment includes an inner stent 6 and an outer stent 11. The inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com