A continuous numerical control pipe bending machine

A pipe bender and sliding connection technology, applied in safety equipment, feeding devices, manufacturing tools, etc., can solve problems such as low production efficiency, lack of continuity in pipe benders, cumbersome operation steps, etc., to improve processing efficiency, Guarantee the effect of stability and strong stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

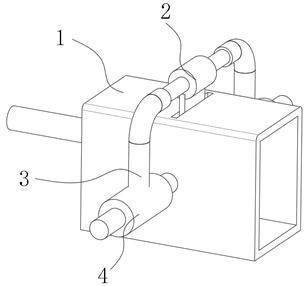

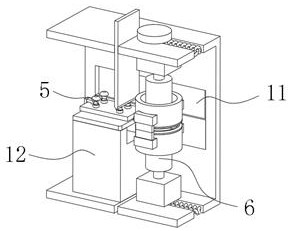

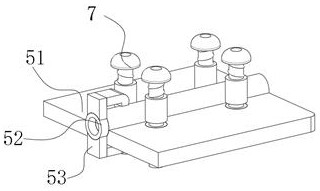

[0029] use Figure 1-Figure 6 A continuous numerical control pipe bending machine according to an embodiment of the present invention is described as follows.

[0030] Such as Figure 1-Figure 6 As shown, a continuous numerical control pipe bending machine according to the present invention includes a processing box 1, which is characterized in that: the top of the inner cavity of the processing box 1 is provided with a cutting groove, and the top of the inner cavity of the processing box 1 is cut The groove is slidably connected with a vertical cutting blade 2, and the top of the vertical cutting blade 2 is fixedly connected with a moving sleeve arm 3, and the two ends of the inner wall of the moving sleeve arm 3 are slidably connected with an auxiliary shaft 4. The rear end of the auxiliary shaft 4 is fixedly connected to the front of the outer surface of the processing box 1 , and a thrust motor is fixedly connected to one side of the outer surface of the auxiliary shaft 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com