Patents

Literature

30results about How to "Save cutting process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

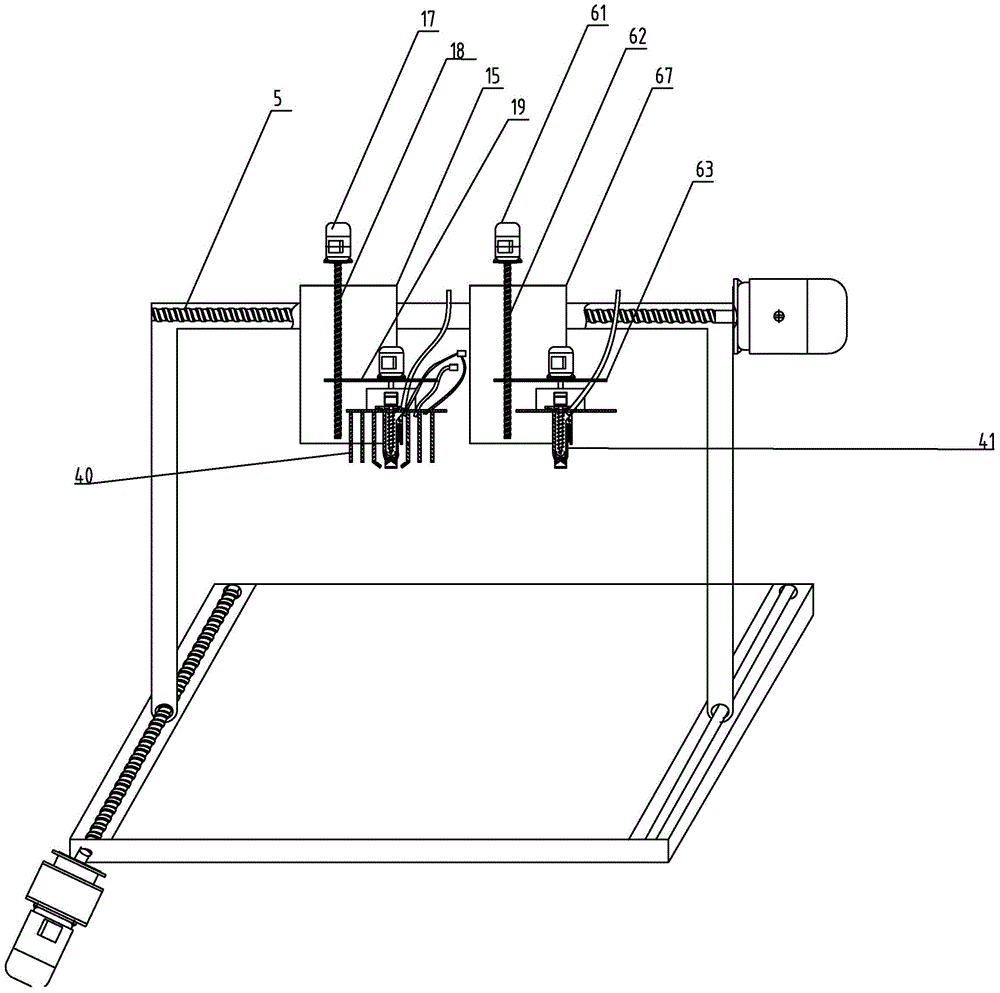

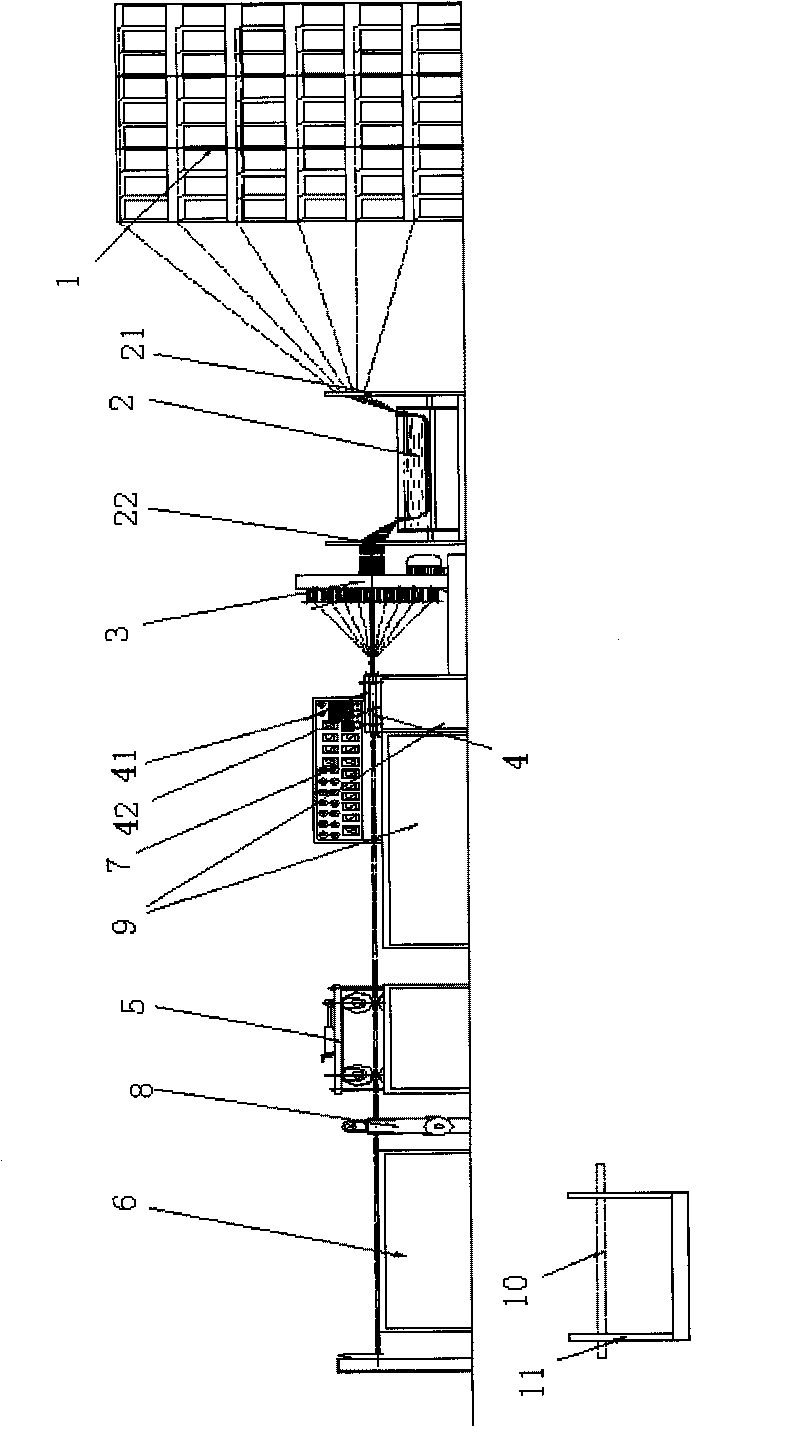

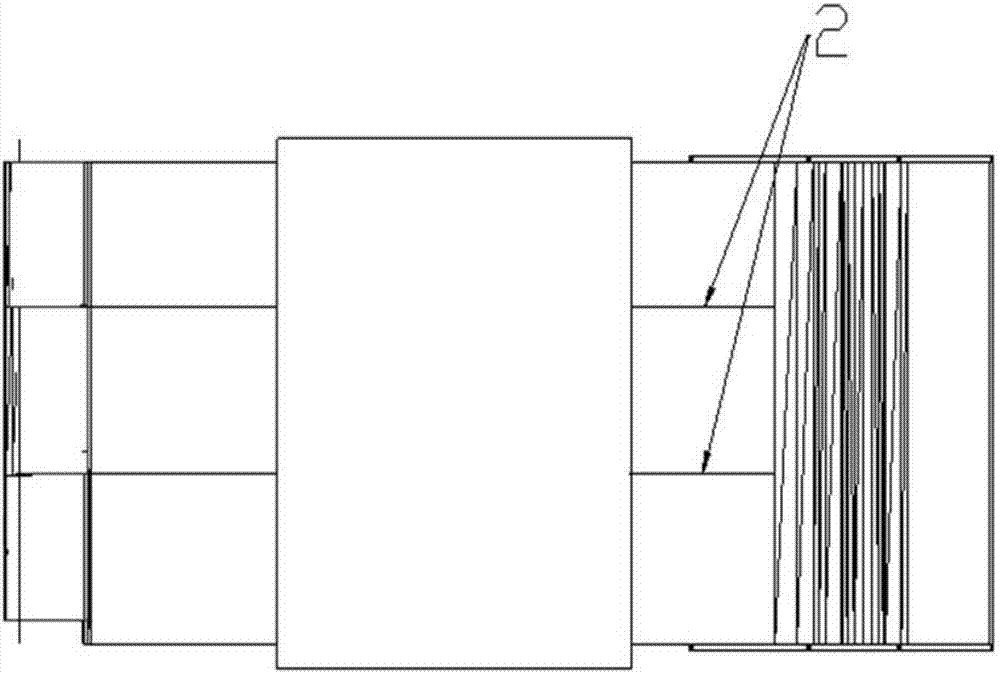

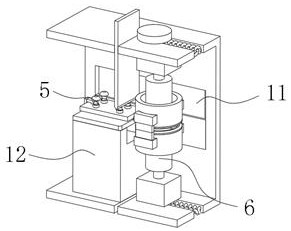

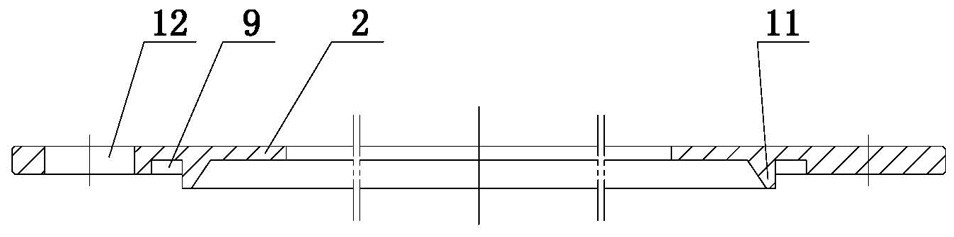

Numerically-controlled drilling and milling machine

InactiveCN103567764ASave cutting processIncrease productivityOther manufacturing equipments/toolsMetal working apparatusEngravingEngineering

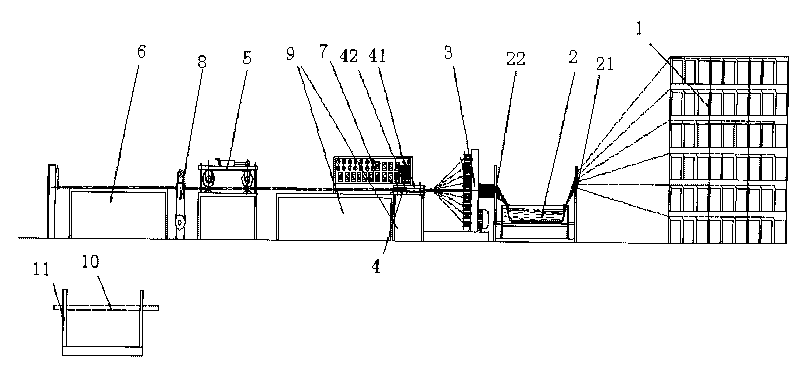

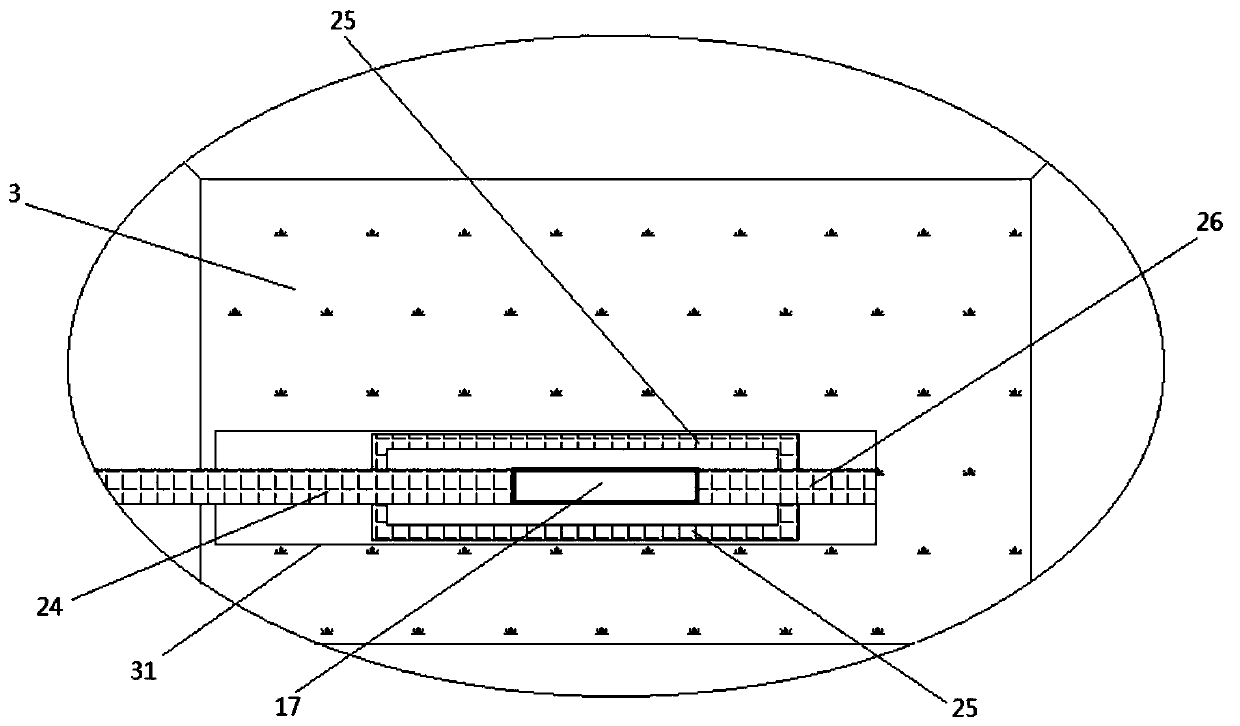

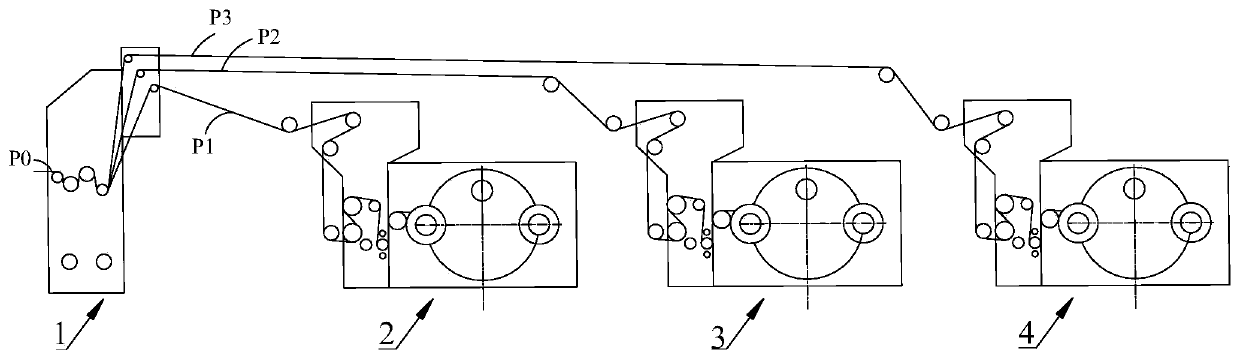

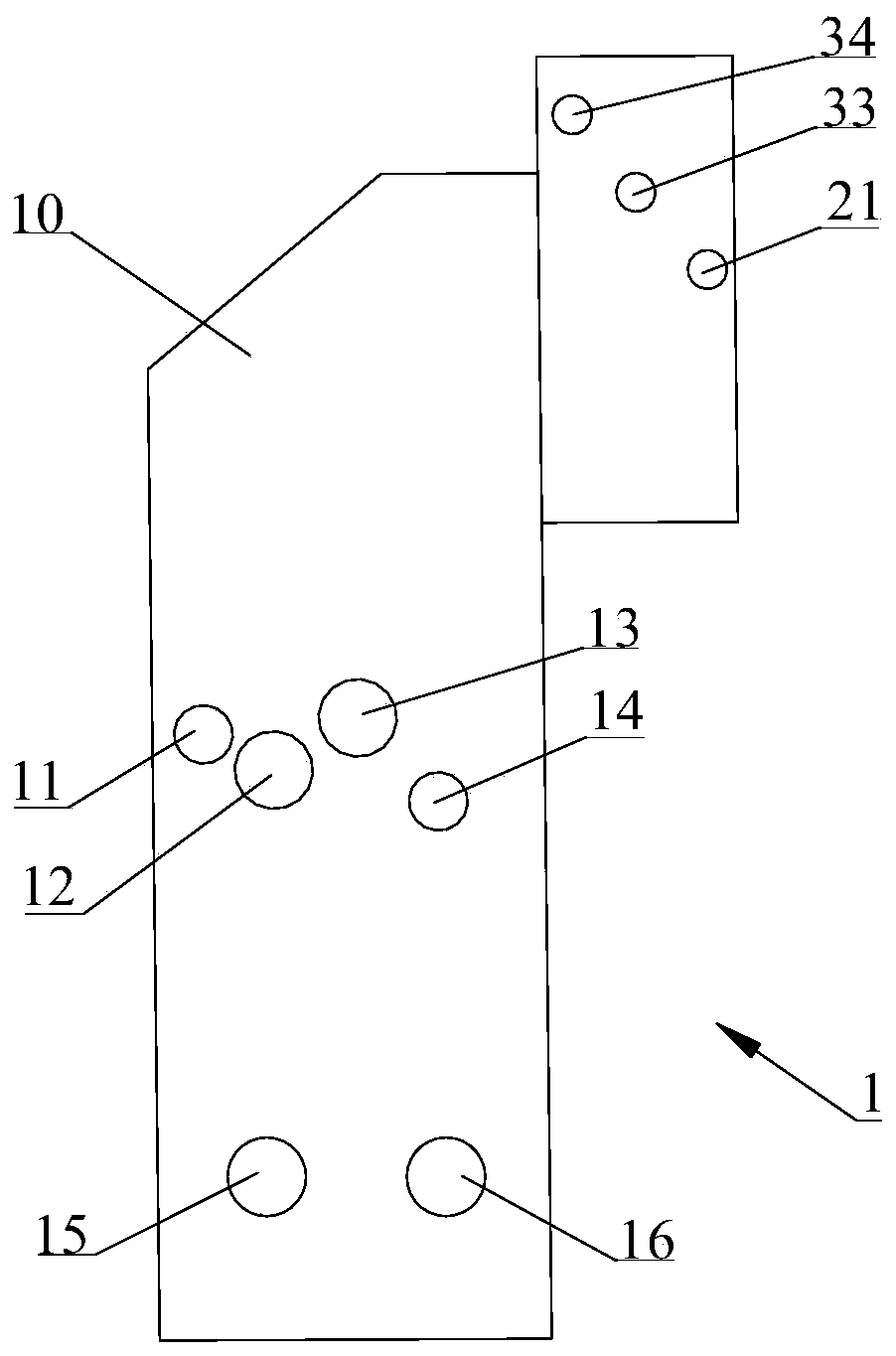

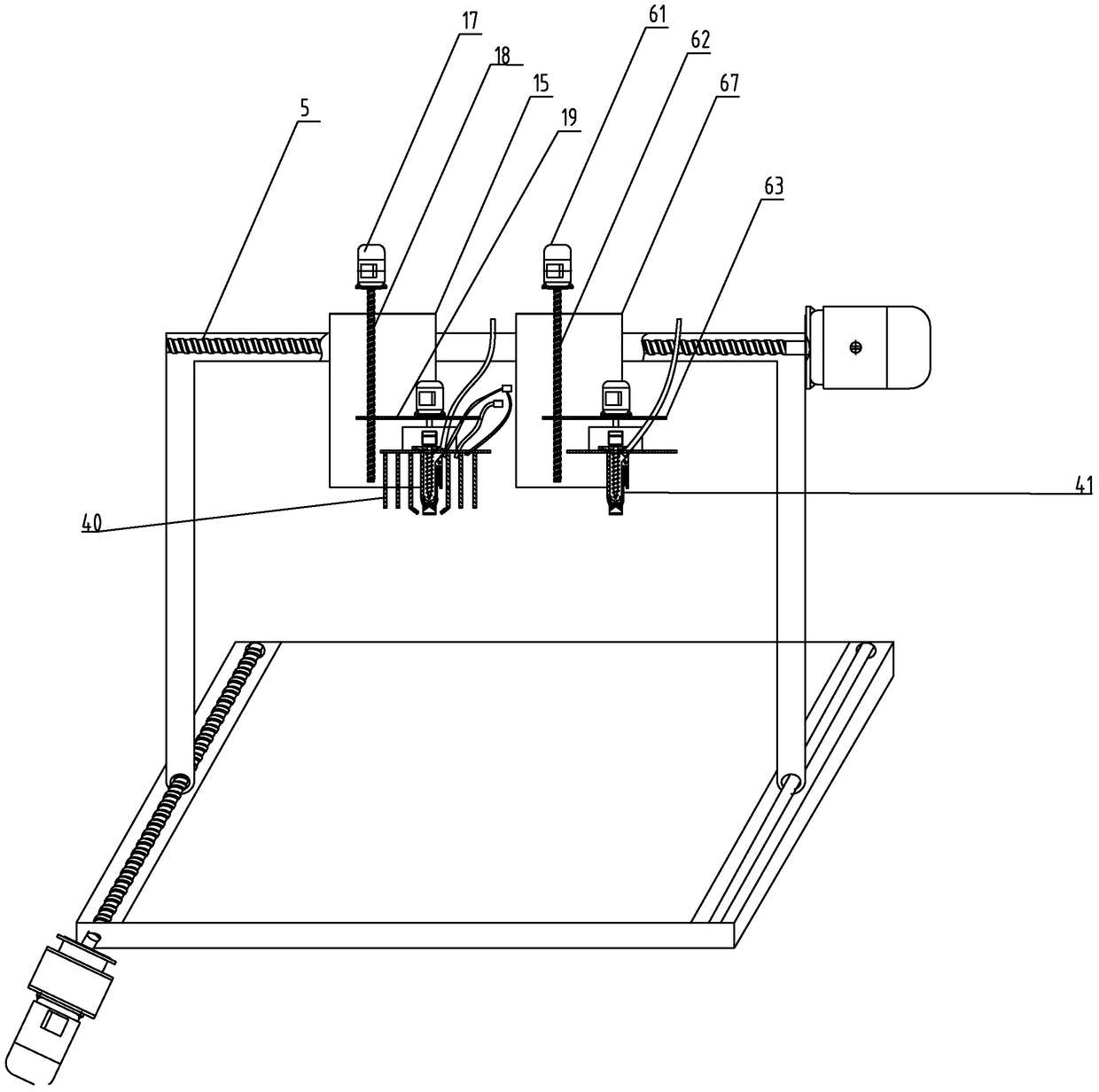

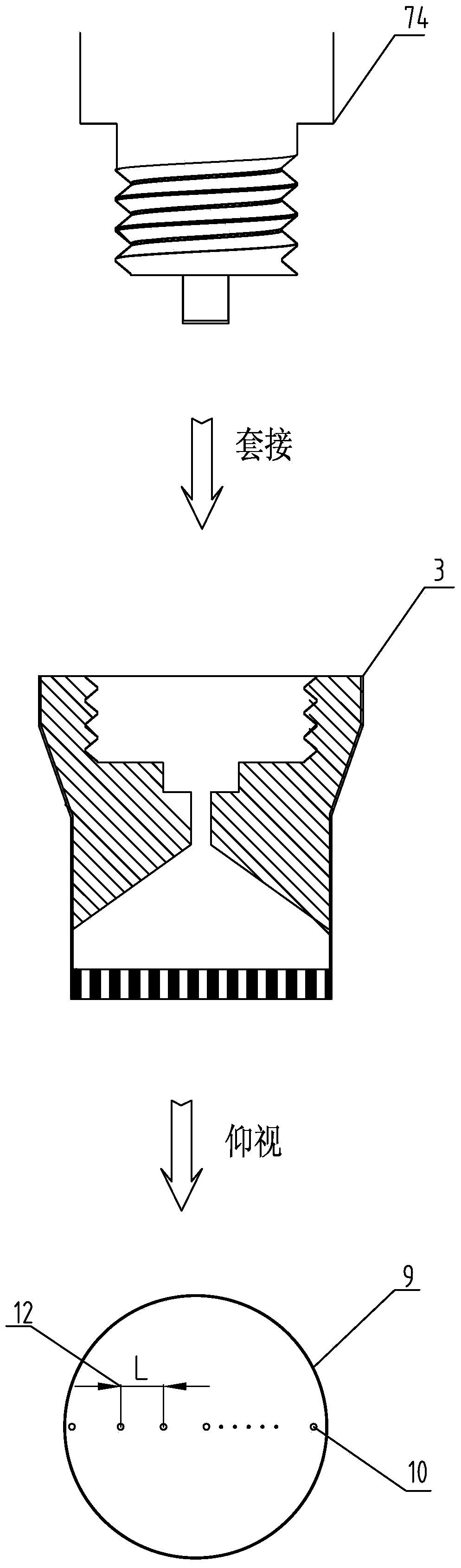

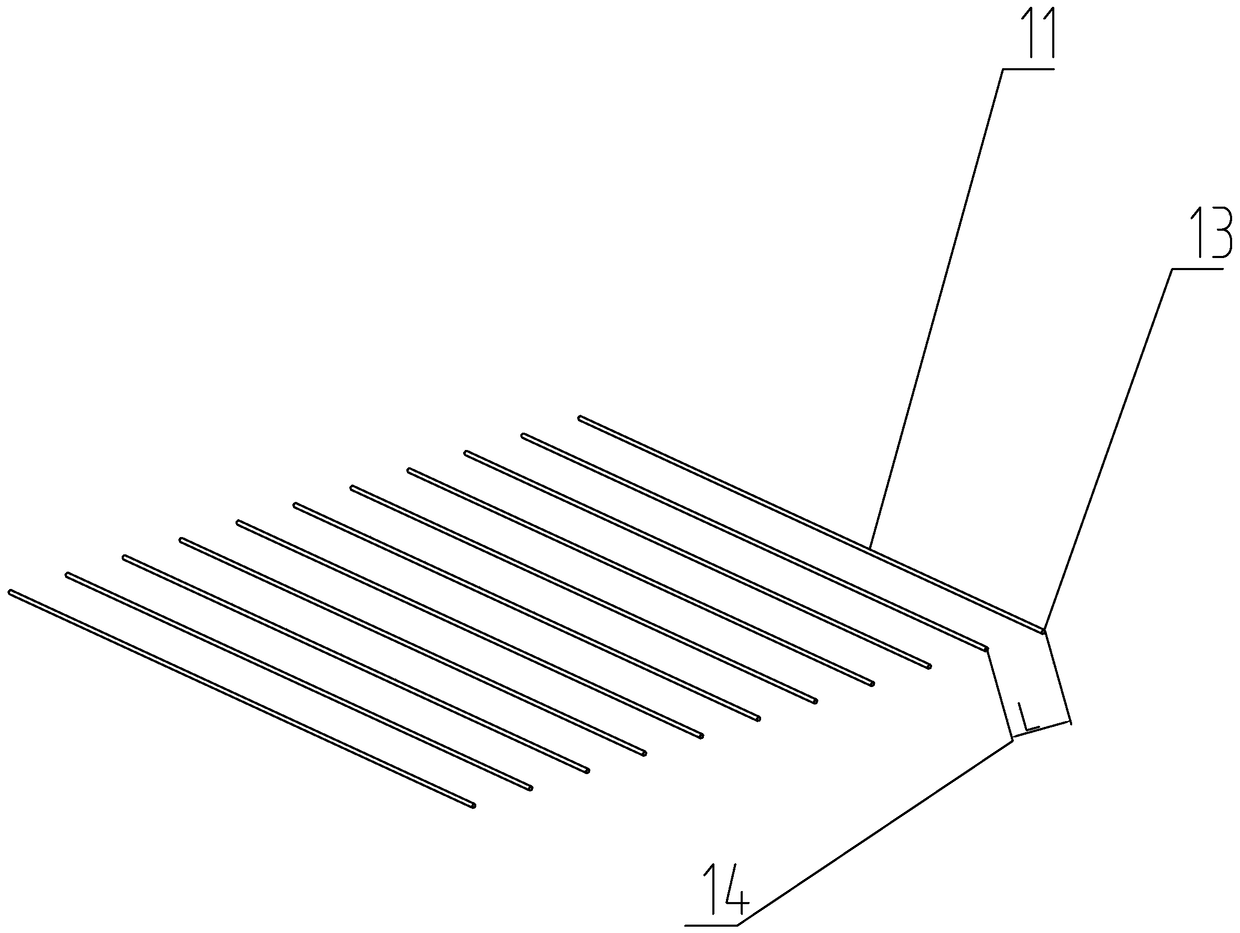

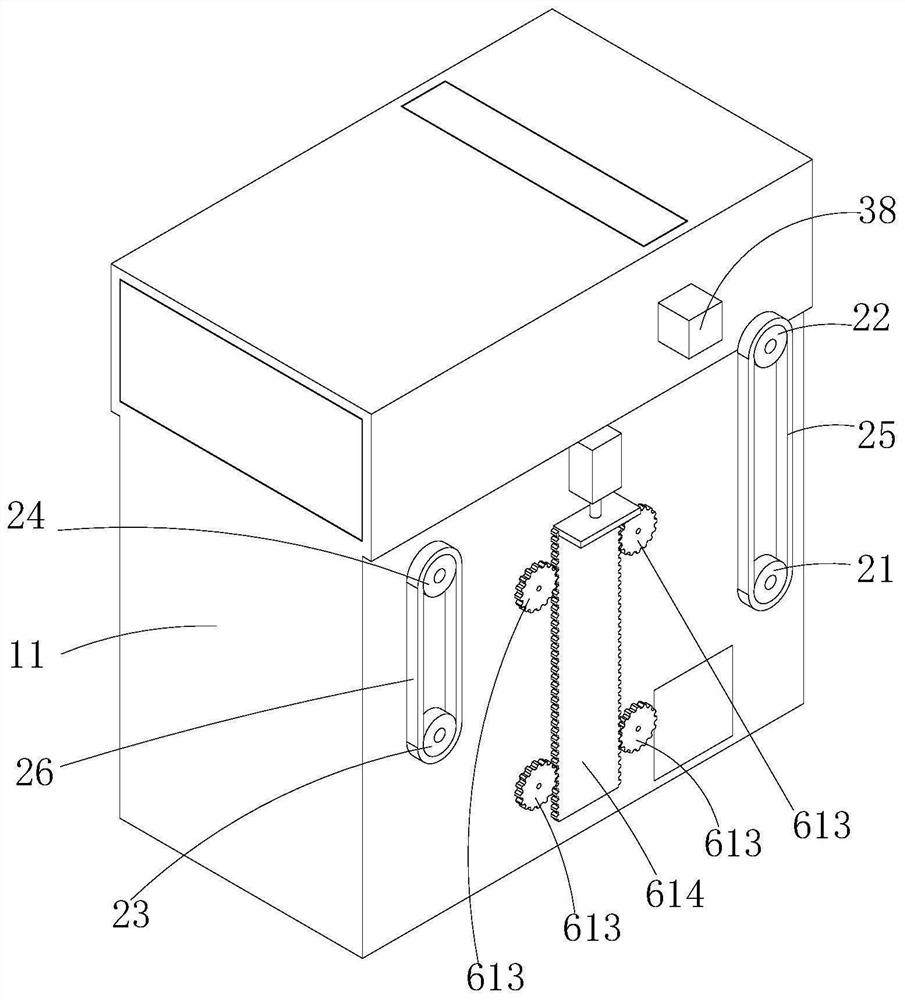

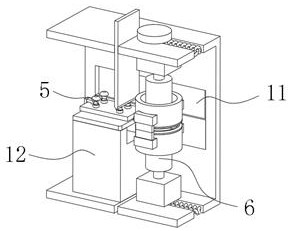

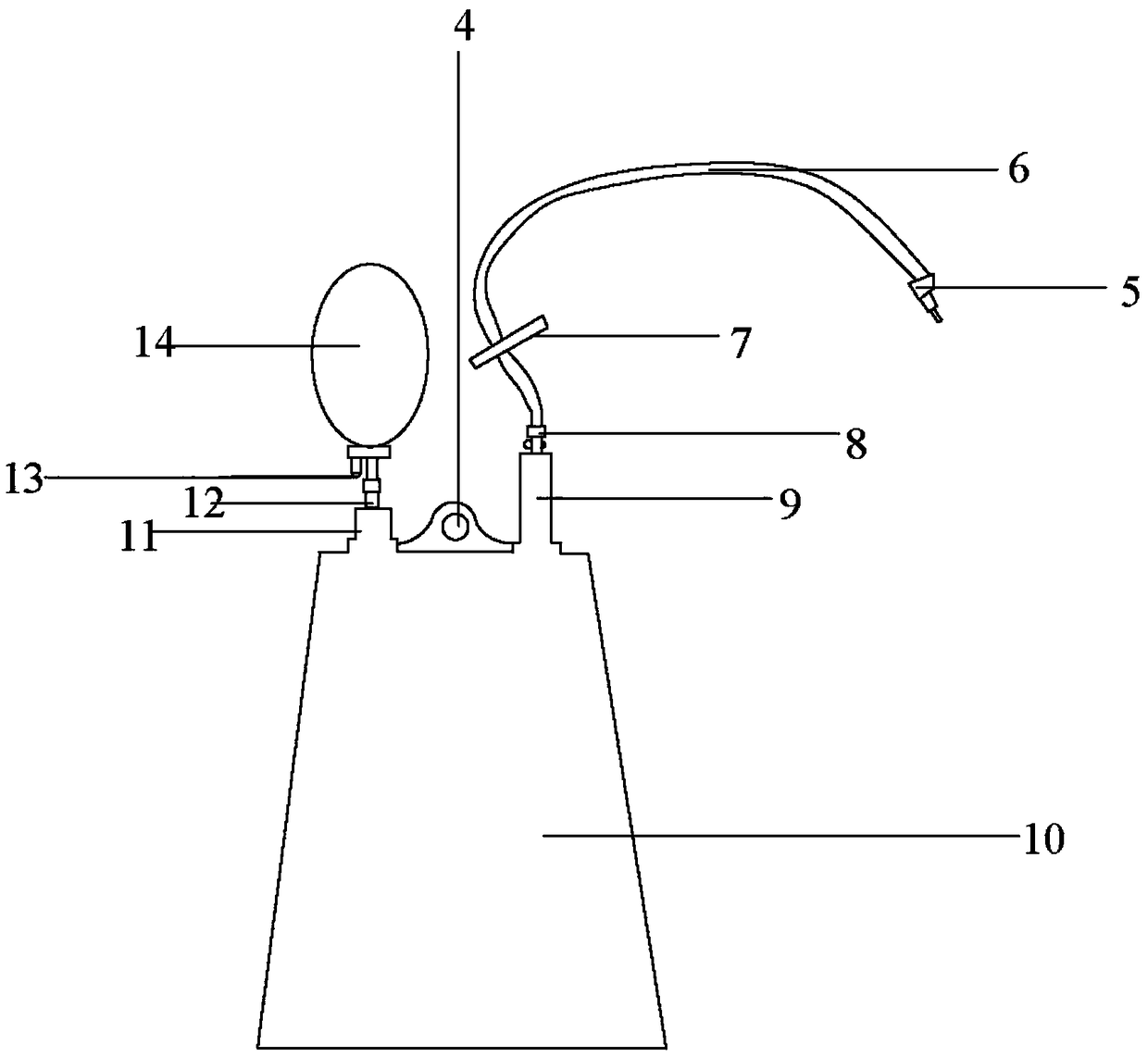

The invention discloses a numerically-controlled drilling and milling machine. The numerically-controlled drilling and milling machine comprises a machine frame. A drilling and milling mechanism is arranged on the machine frame. A feeding mechanism is arranged on one side of the machine frame. A sawing mechanism is arranged on the side, close to the feeding mechanism, of the machine frame and comprises a motor, an arm seat and a cutting tool, wherein the motor is arranged at one end of the arm seat, the cutting tool is arranged at the other end, close to the feeding mechanism, of the arm seat, the motor is connected with the cutting tool through a transmission belt, the arm seat is further provided with a swinging arm seat connected with a swinging arm air cylinder, and the arm seat is controlled to ascend and descend by the swinging arm air cylinder through the swinging arm seat. Because the sawing mechanism is arranged on the side, close to the feeding mechanism, of the machine frame, the arm seat is controlled to ascend and descend by the swinging arm air cylinder of the sawing mechanism through the swinging arm seat and the cutting tool is driven to ascend and descend to cut a profile, metal profiles of any length can be subject to orderly engraving, milling and cutting, and the process that the profiles are cut through cutting tools is omitted. The numerically-controlled drilling and milling machine is high in production efficiency, machining precision and automation degree.

Owner:佛山金皇宇企业孵化器有限公司

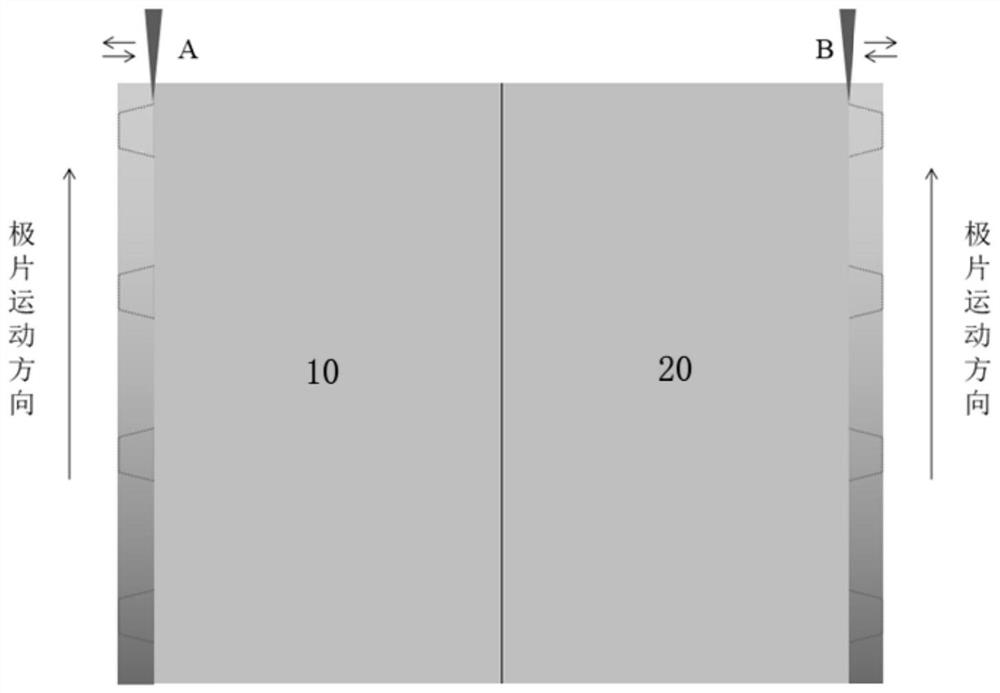

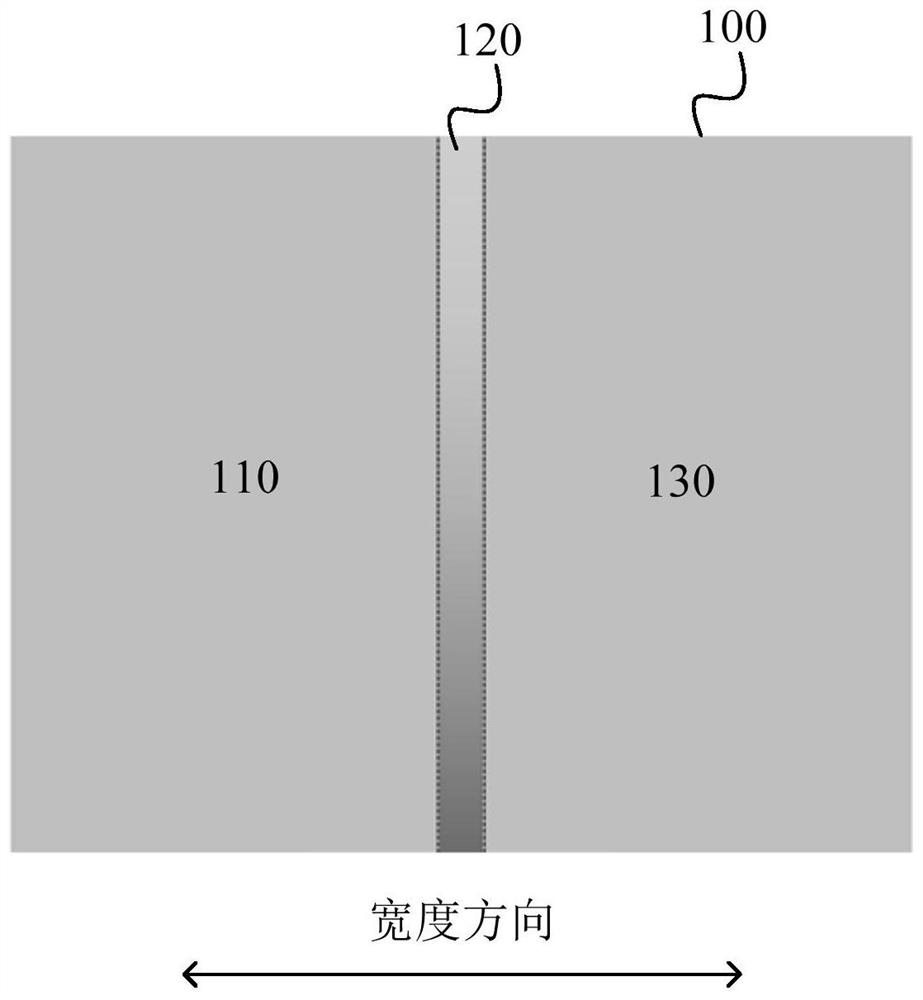

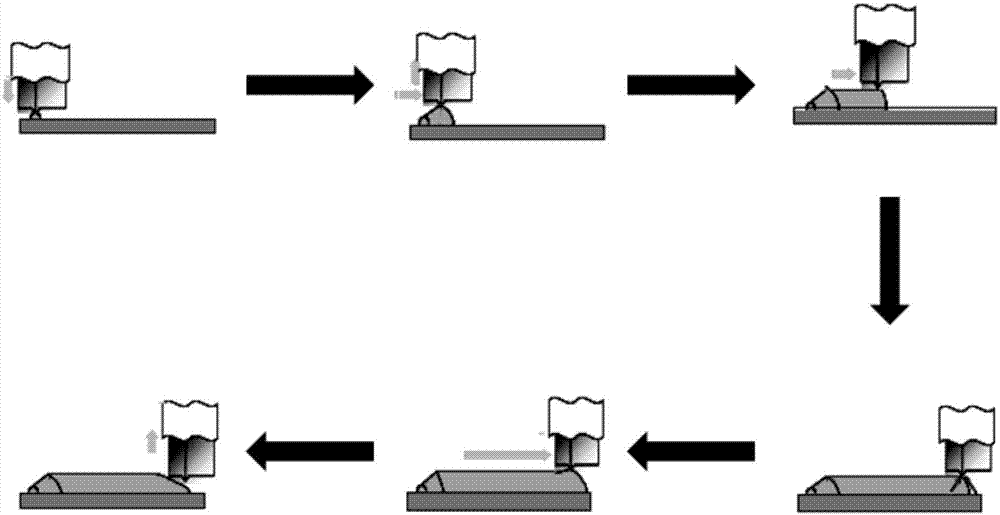

Pole piece laser die-cutting method

InactiveCN111660015ASave cutting processIncrease productivityCell component detailsWelding/soldering/cutting articlesEngineeringPole piece

The invention discloses a pole piece laser die-cutting method. The method comprises the following steps: (1) providing a foil; (2) dividing the surface of the foil into a first coated region, a blankregion and a second coated region, wherein the blank region is positioned between the first coated region and the second coated region; (3) coating electrode slurry to the first coated region and thesecond coated region, roasting and rolling a obtained pole piece in sequence to obtain a pole piece to be die-cut; and (4) utilizing laser to perform lug die-cutting on the blank region to obtain multiple first lugs and multiple second lugs, and dividing the pole piece to be cut into a first pole piece and a second pole piece. The pole piece laser-cutting method disclosed by the invention can cutthe foil while accomplishing lug die-cutting and forming, so that lug processing cost is greatly reduced.

Owner:昆山聚创新能源科技有限公司

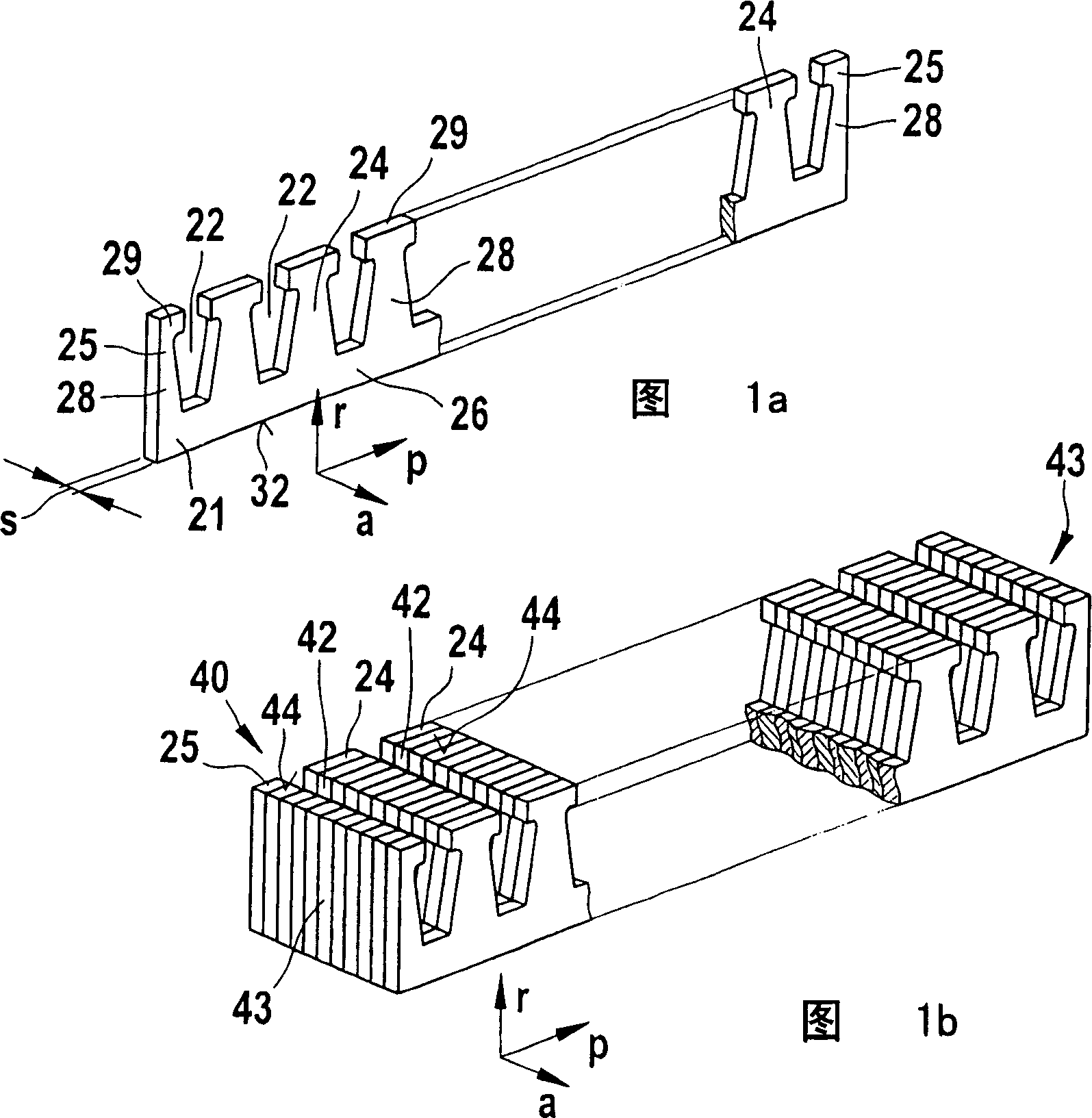

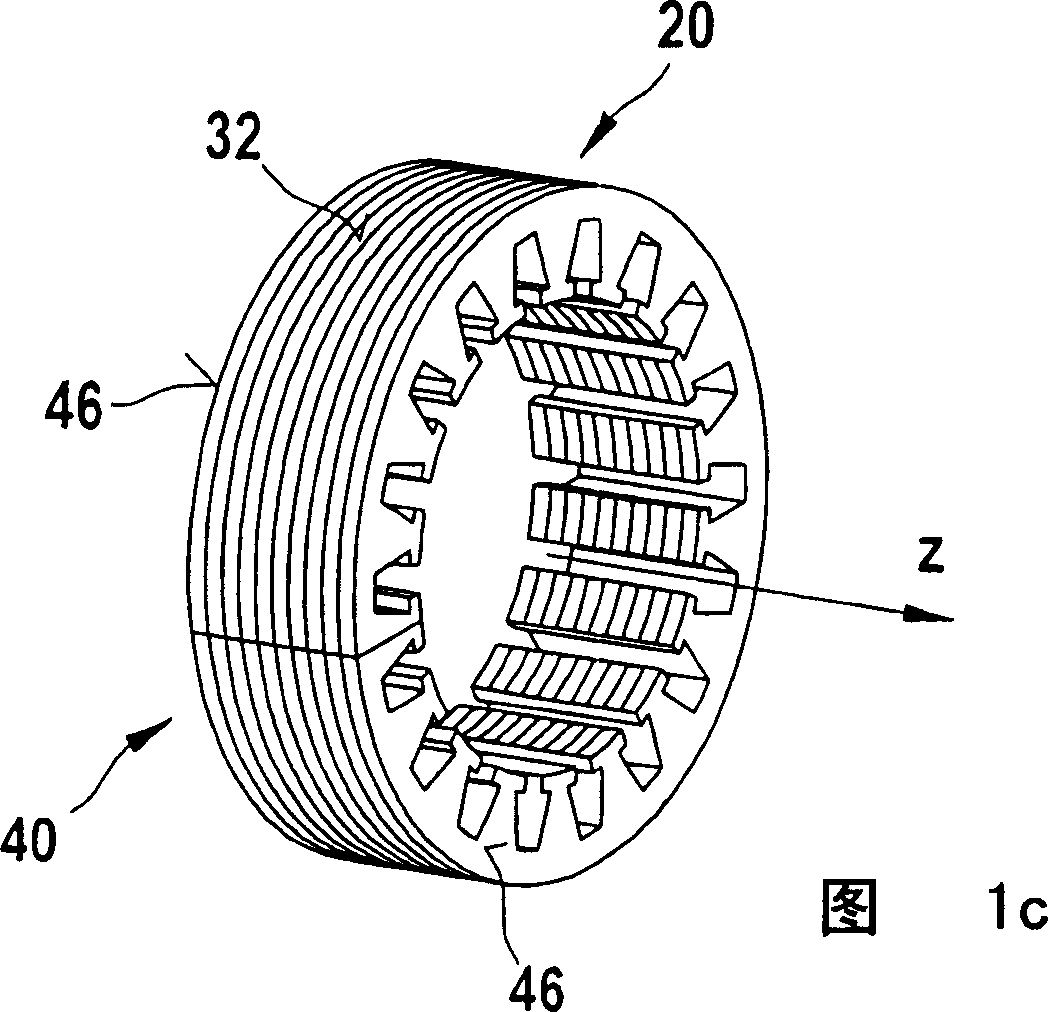

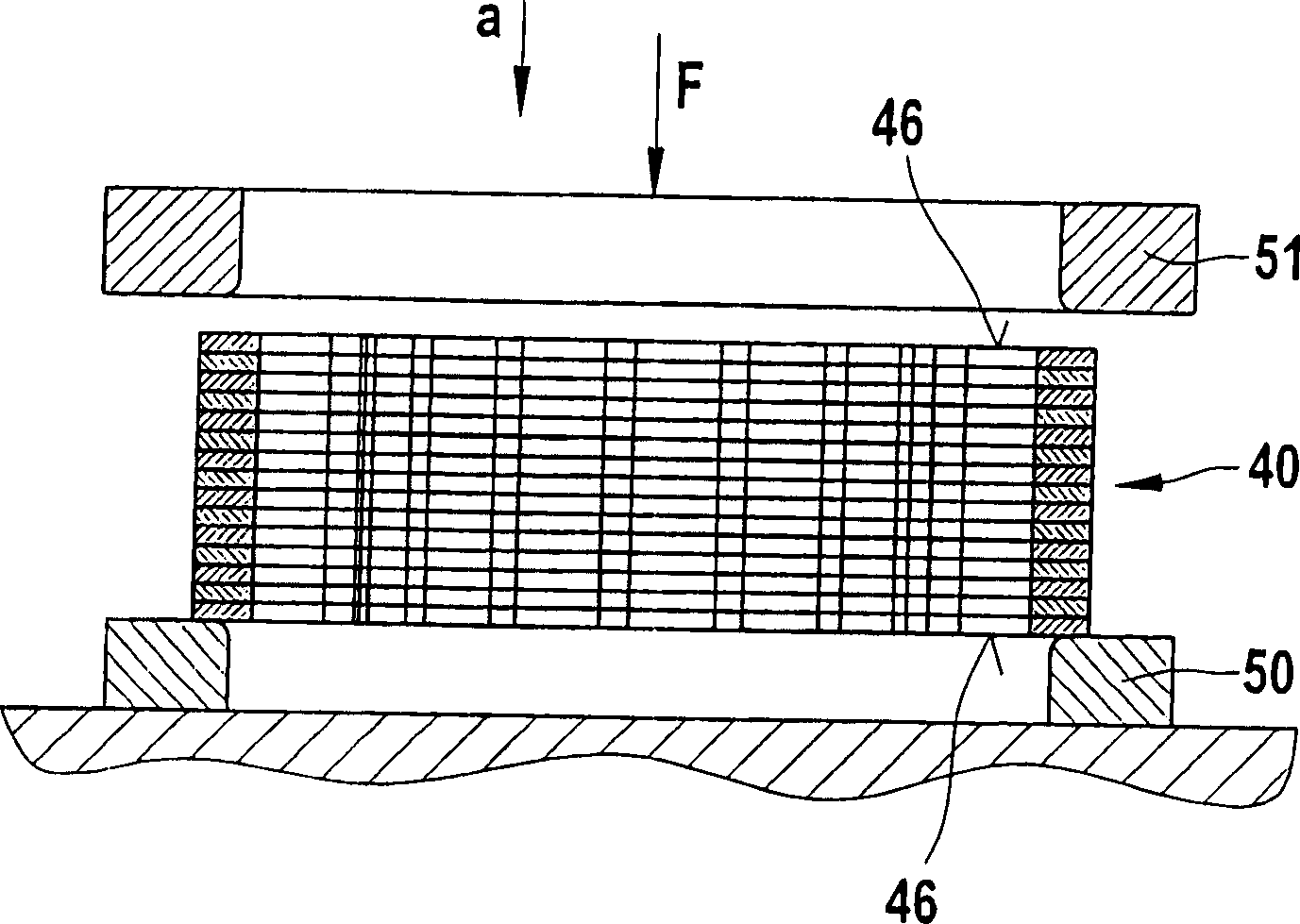

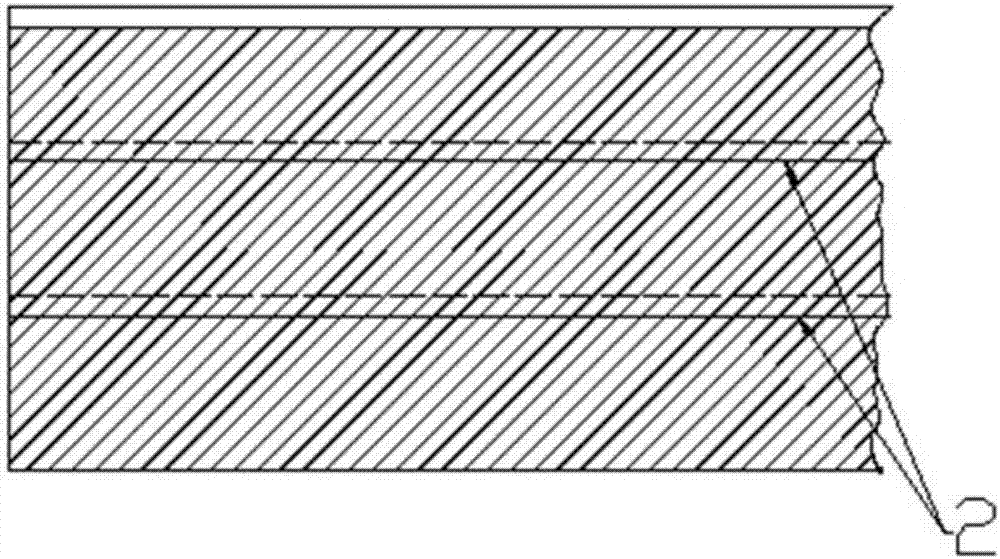

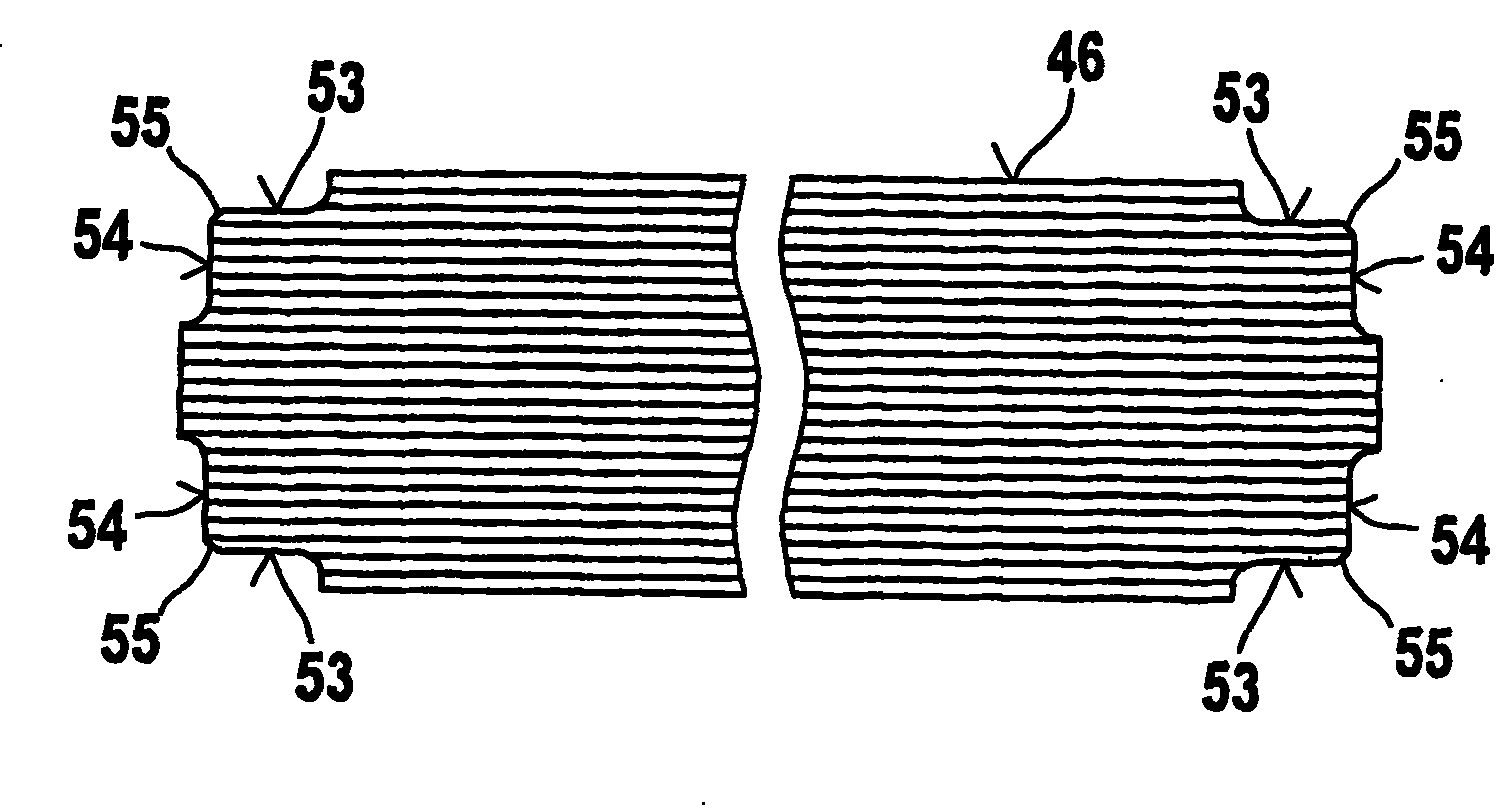

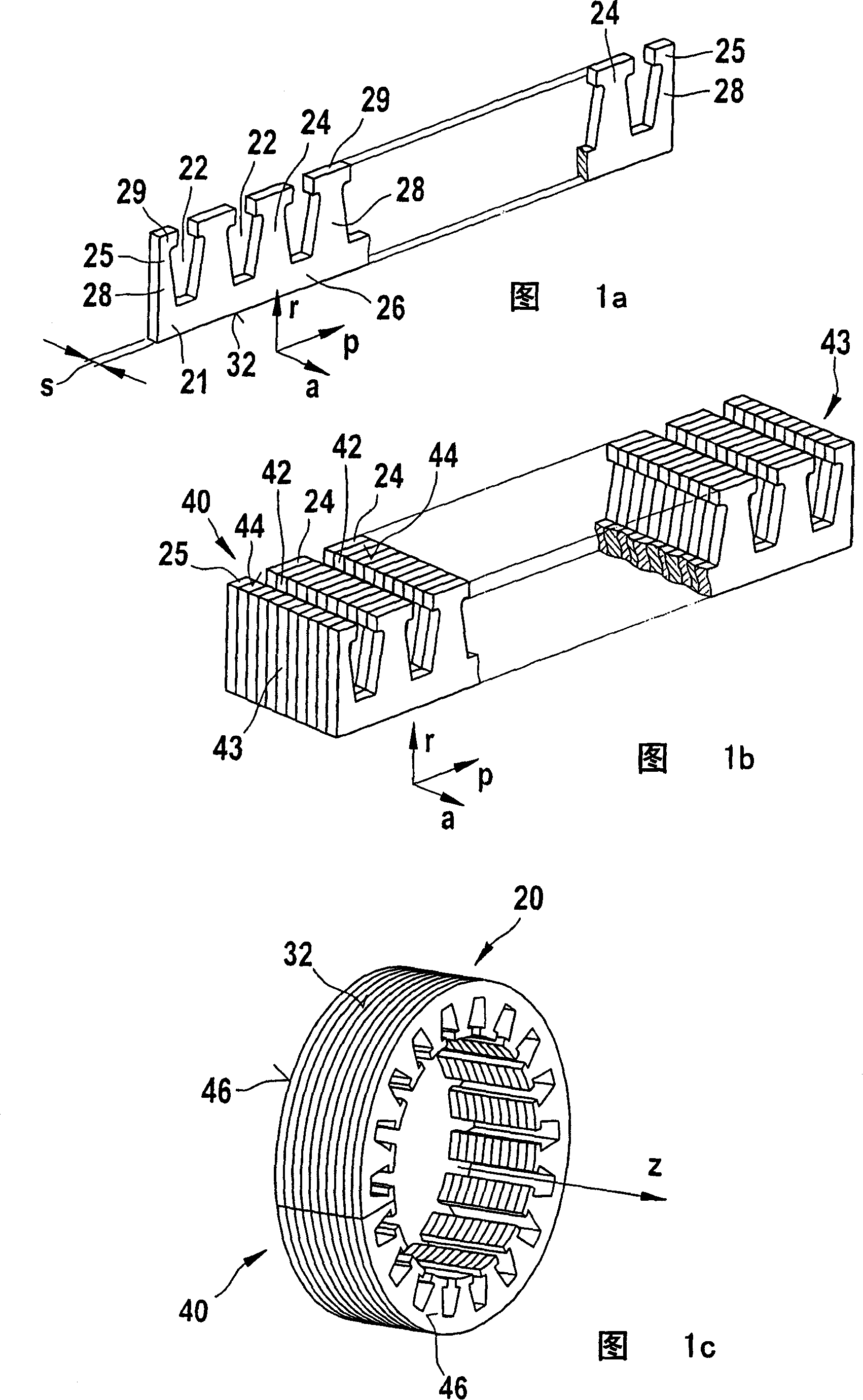

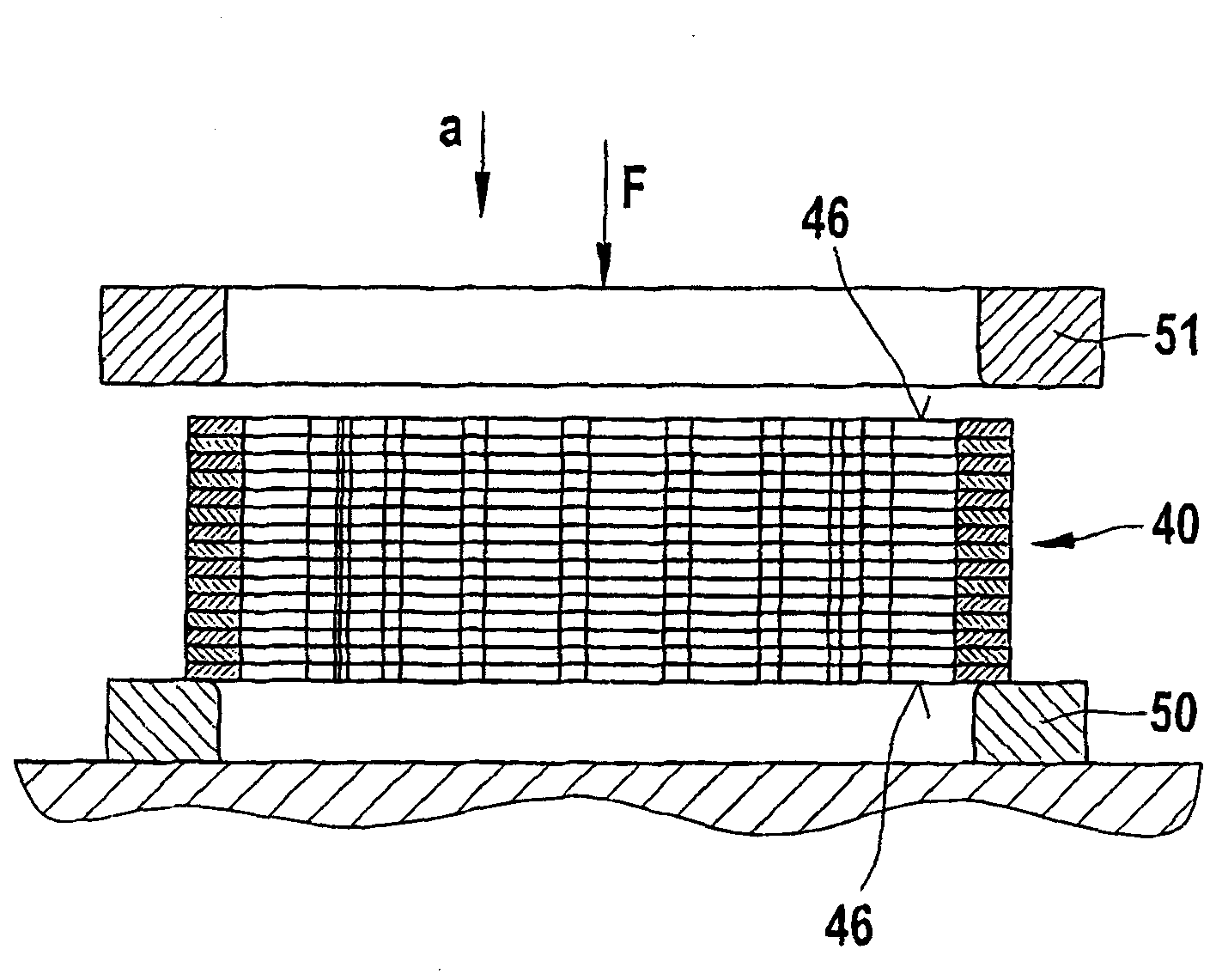

Method for the production of a stator and stator produced according thereto

InactiveCN1902801AReduce the elastic deformation componentReduce the degree of clampingMagnetic circuit stationary partsManufacturing stator/rotor bodiesThin sheetElectrical and Electronics engineering

Owner:SEG AUTOMOTIVE GERMANY GMBH

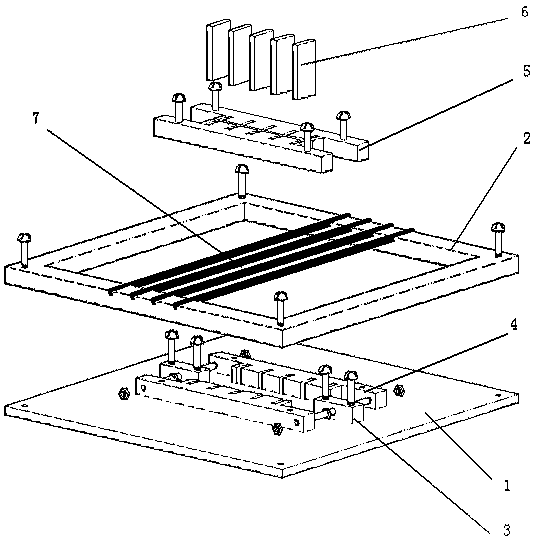

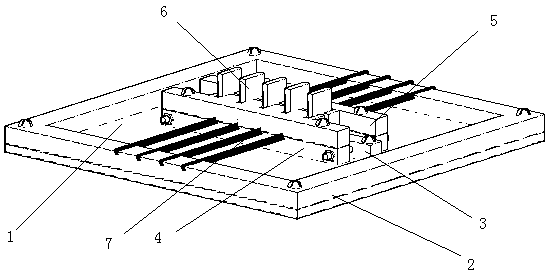

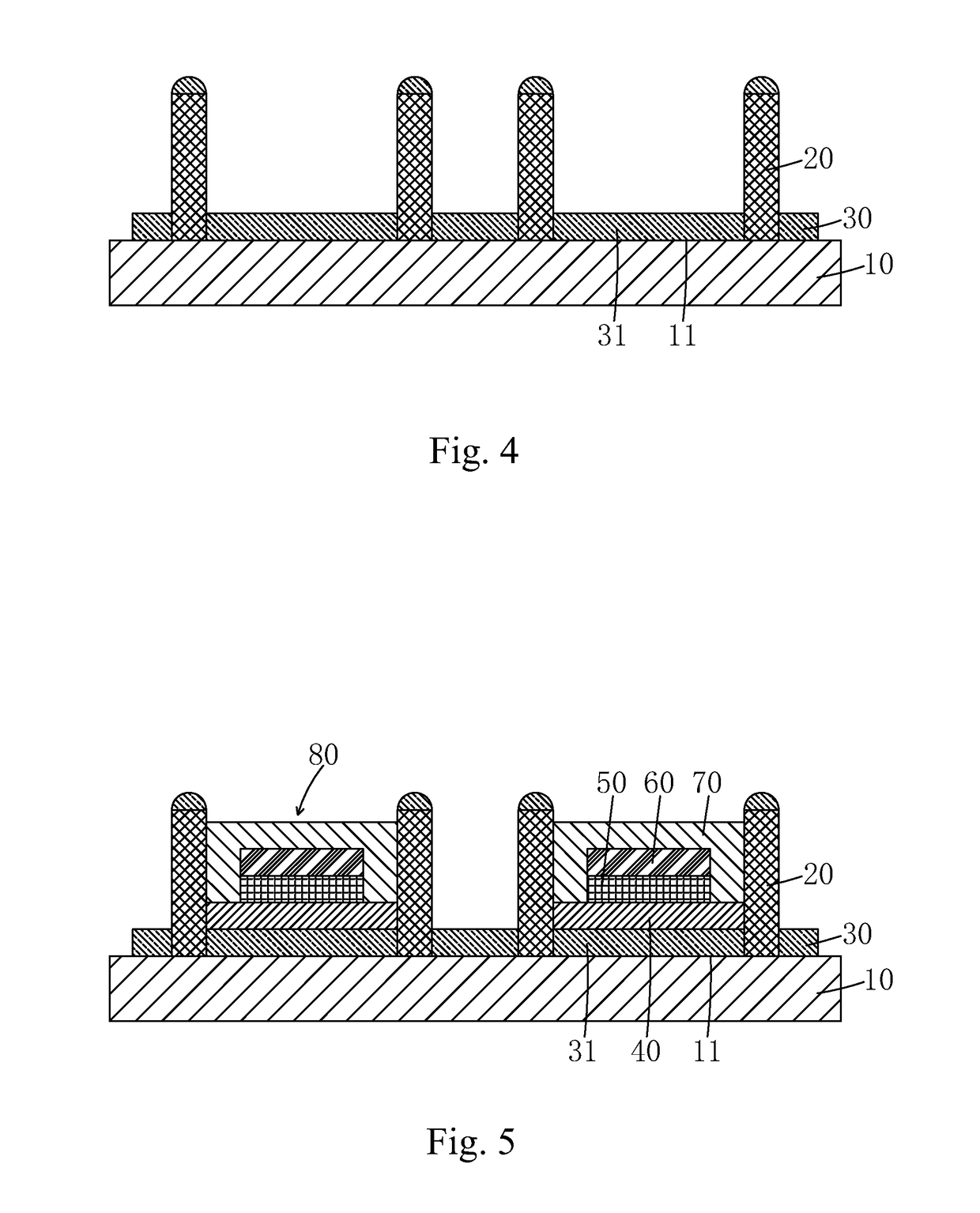

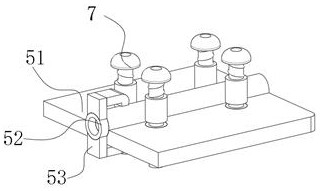

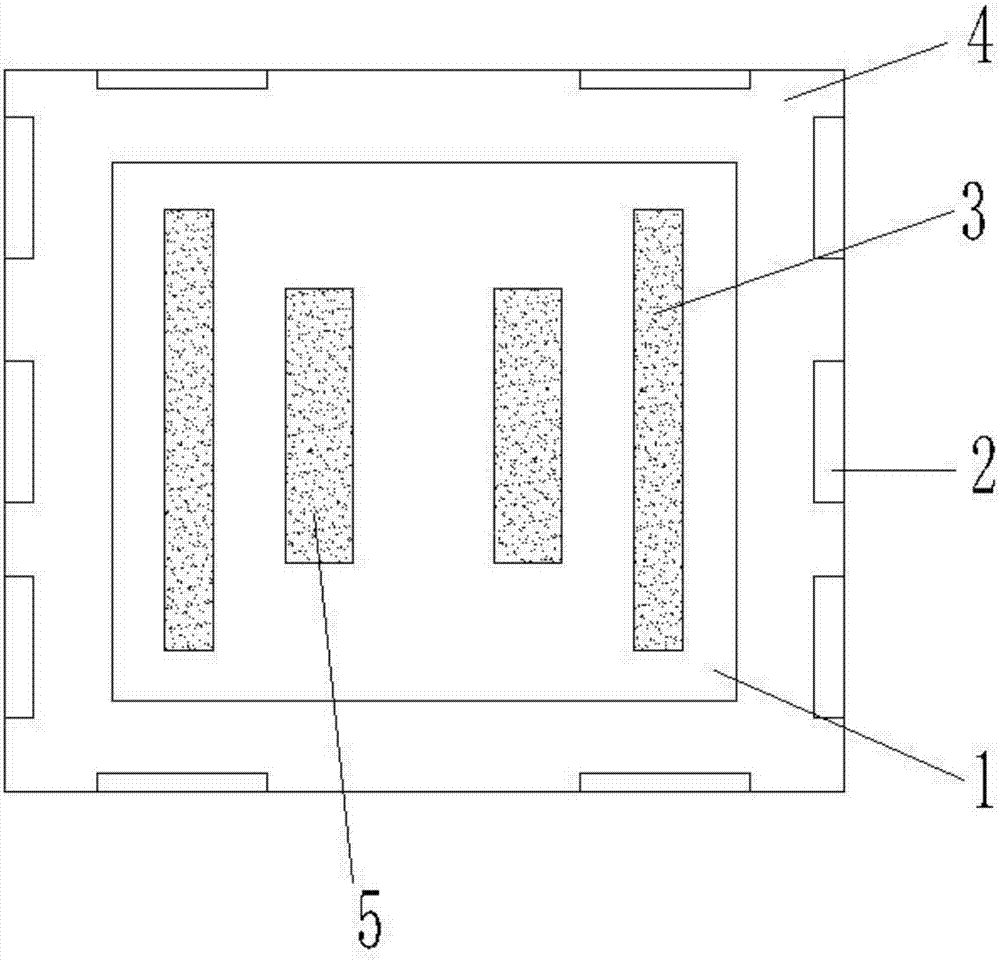

Variable thickness single fiber pull-out cement-based test piece mould and adjusting and testing method

ActiveCN109822724ASimple structureEasy to operatePreparing sample for investigationCeramic shaping apparatusVariable thicknessComputer module

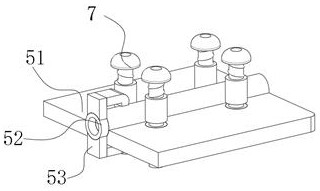

The invention provides a variable thickness single fiber pull-out cement-based test piece mould and an adjusting and testing method. The mould comprises a bottom plate, a framework, stand columns, side wing upper and lower modules and partition plates. All the portions are connected through screws and the like. A test piece thickness adjusting method based on the mould is provided, and a specified-thickness single fiber pull-out cement-based test piece can be obtained on the premise that the test piece is not cut. By means of the mould and the method provided by the invention, a plurality of single fiber pull-out cement-based test pieces can be poured at a time, the structure is simple, the operability is high, demoulding is easy, and in addition, the test pieces are spaced through the partition plates and independently formed; and meanwhile, the thicknesses of the poured test pieces can be adjusted by adjusting the positions of the side wing modules, accordingly, a cutting process ina traditional method is omitted, and the risk of damage to a fiber / substrate interface due to cutting is avoided.

Owner:SOUTHEAST UNIV

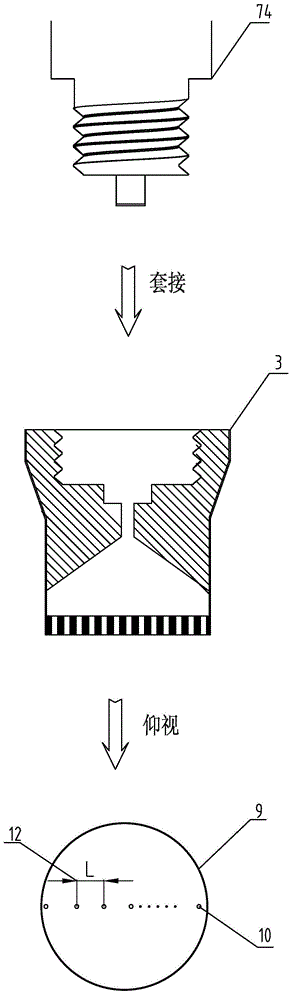

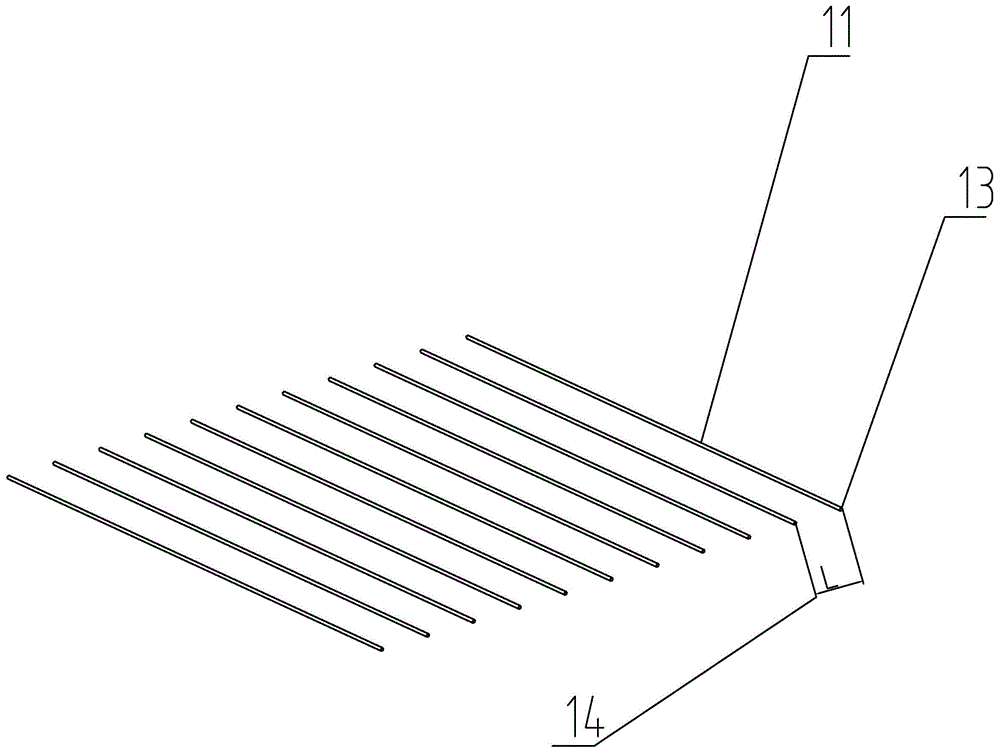

Single-face forming method of clothing and 3D printing device

ActiveCN105984138AEliminate the need for suturesElimination of melt spinning process3d printMechanical engineering

The invention discloses a single-face forming method of clothing and a 3D printing device and belongs to the field of FDM-type 3D printing. The device includes a long-distance multi-hole printing head and a double-row-hole filling printing head, and the method is a single-face forming method. The method includes the steps of: printing a cloth fabric layer with the long-distance multi-hole printing head with an edge strip at a joint position remained; printing a water-soluble material interlayer with the double-row-hole filling printing head or covering the cloth fabric layer with a separation board, folding-up the edge strip, and printing a cloth fabric layer with the long-distance multi-hole printing head; holt-melting the edge strip with the third cloth fabric layer together, and finally dissolving the water-soluble material interlayer or removing the separation board to form clothing. The invention achieves production of a clothing and wearing product through 3D printing technology. The method saves cost and reduces processing time and can be used for producing the clothing being more flexible in styles, and can replace a part of conventional process technologies for producing the clothing and wearing product.

Owner:CHANGZHOU DONGKE ELECTRONICS TECH CO LTD

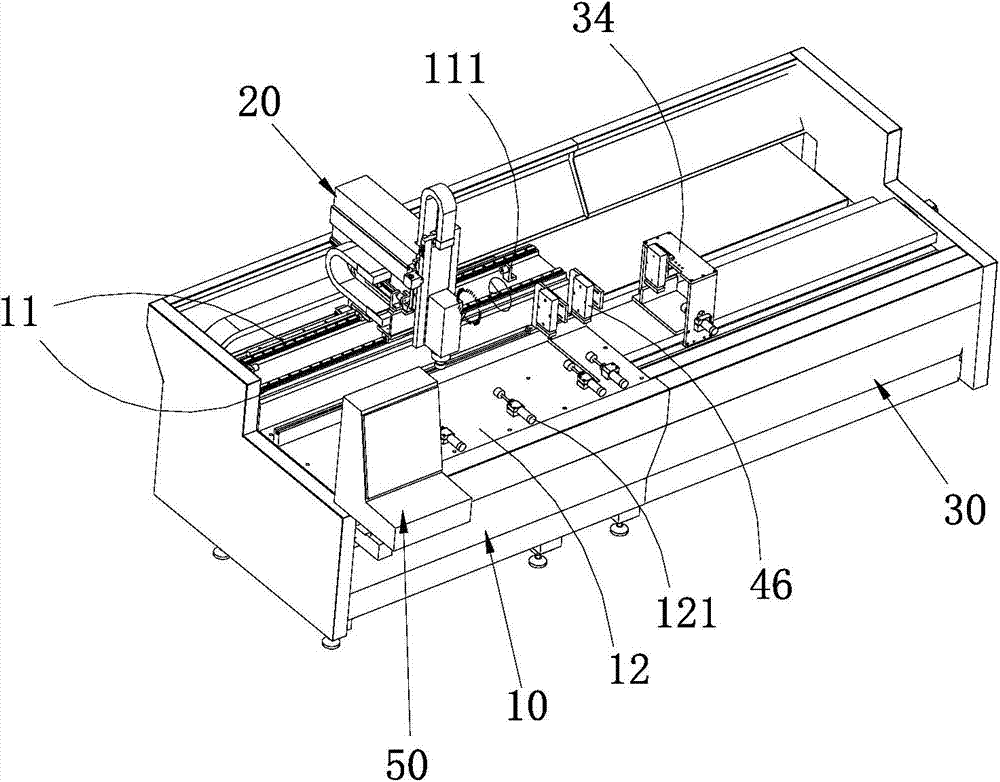

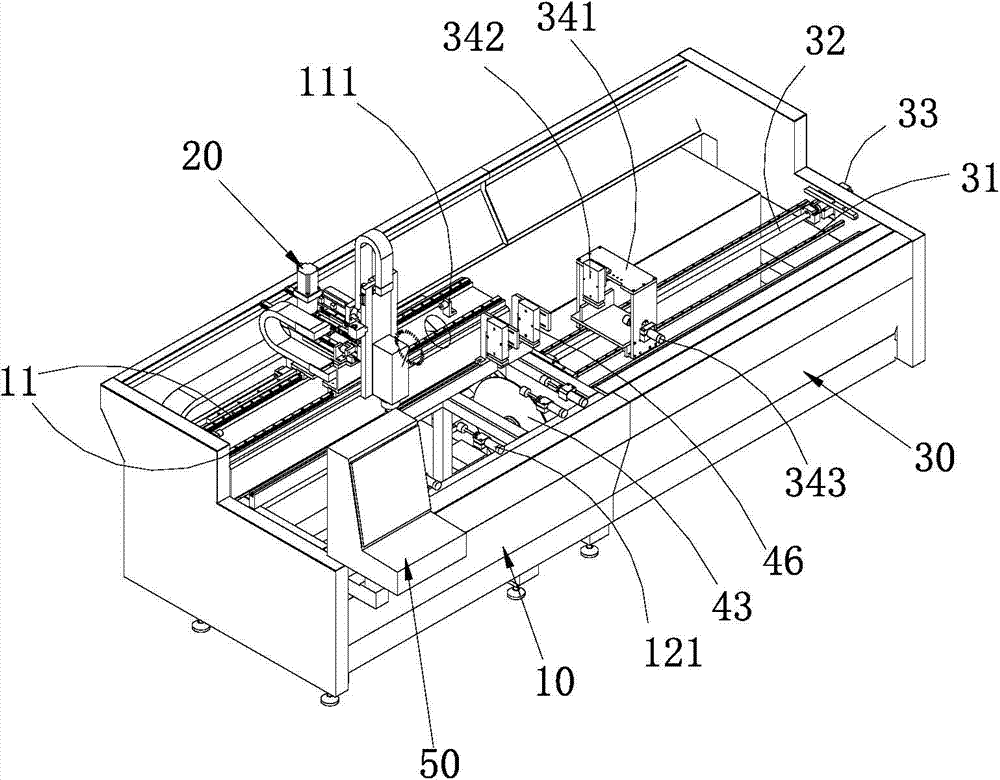

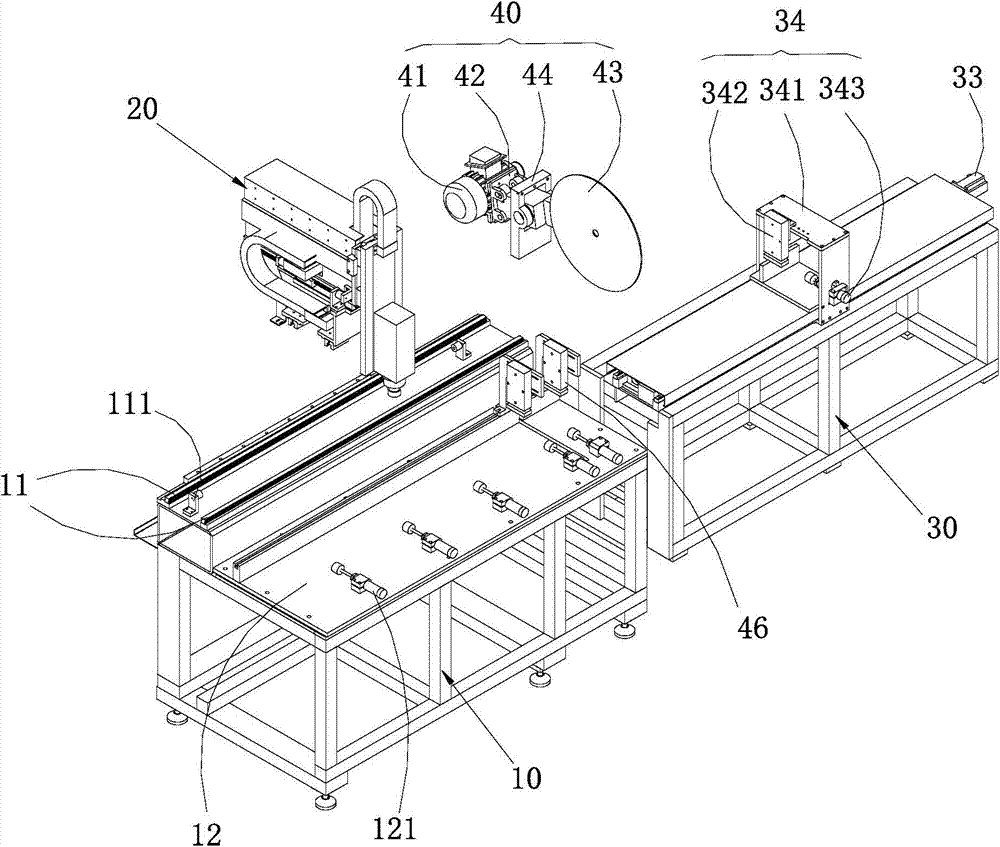

Automatic cutting device and automatic cutting equipment

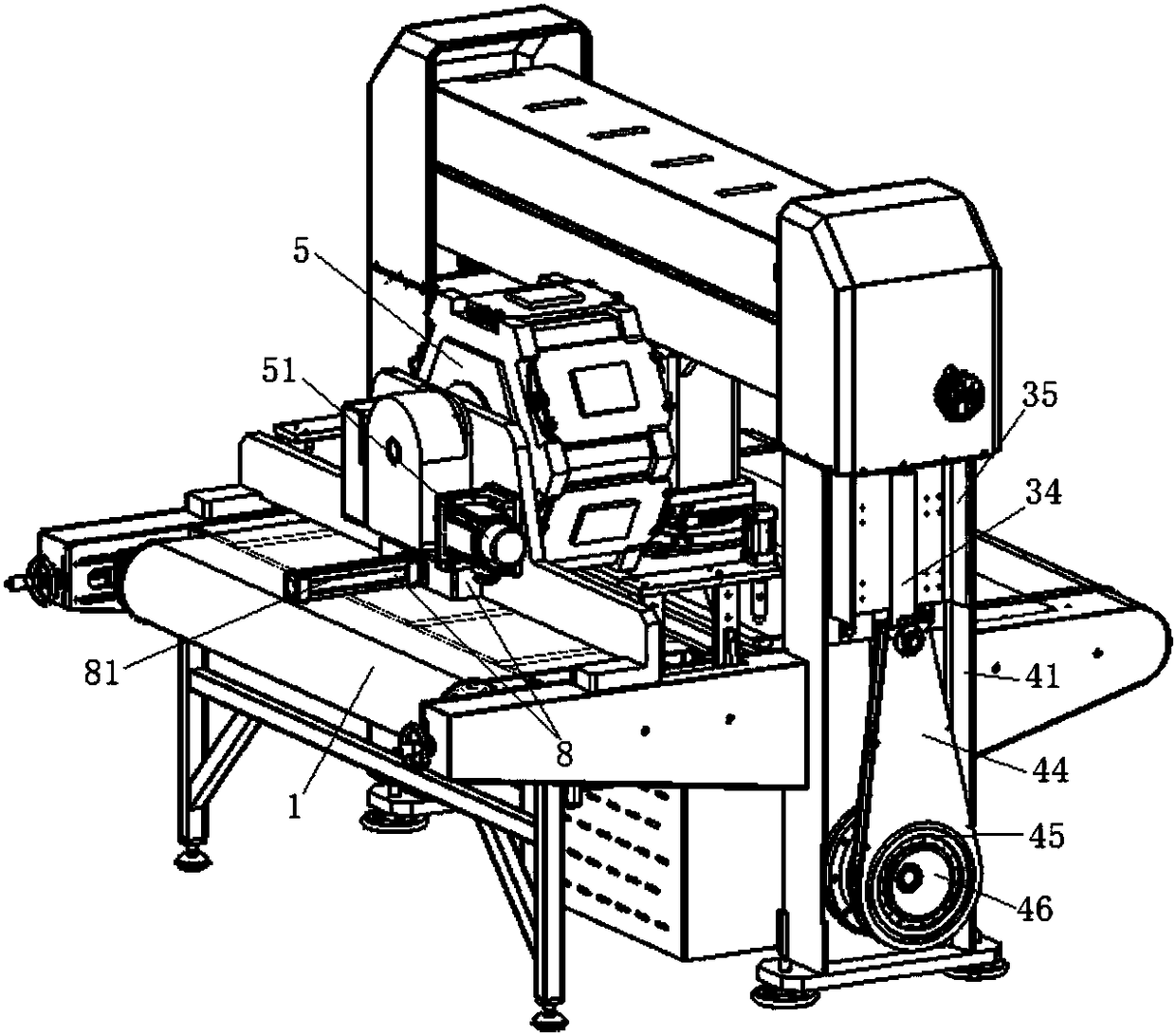

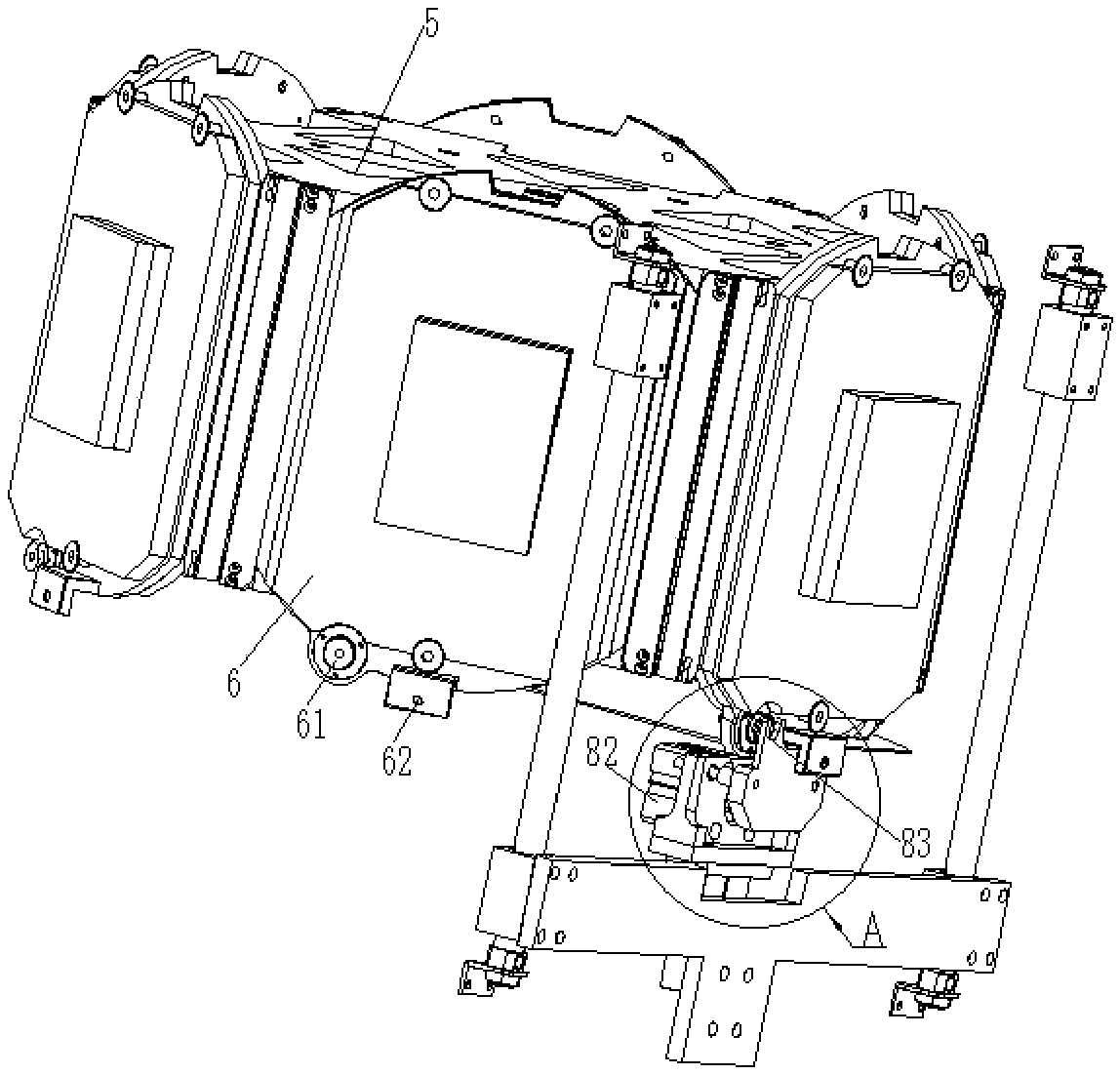

PendingCN108556053ASave cutting processReduce distanceMetal working apparatusEngineeringMechanical engineering

The invention provides an automatic cutting device and automatic cutting equipment and relates to the technical field of shoe, clothe, bag and luggage industries. The automatic cutting device comprises a conveyer belt used for bearing and conveying materials to be cut, a cutting seat and a movement mechanism, wherein cutters can be installed on the cutting seat, the movement mechanism controls thecutting seat to conduct transverse cutting on the materials to-be-cut once. The materials to be cut are horizontally placed on the conveyer belt, and the length direction of the materials to be cut is identical with the horizontal conveying direction of the conveyer belt. The cutting seat is fixed to the movement mechanism and located above the conveyer belt. The conveyer belt can conduct periodical movement when the moment mechanisms work. The automatic cutting device and the automatic cutting equipment relieve the technological problems that in the prior art, cutting equipment needs manualintervention, so that the cutting efficiency is low, the utilization rate of a material strip is low, and the cutting cost is high.

Owner:温岭市六菱机械有限公司

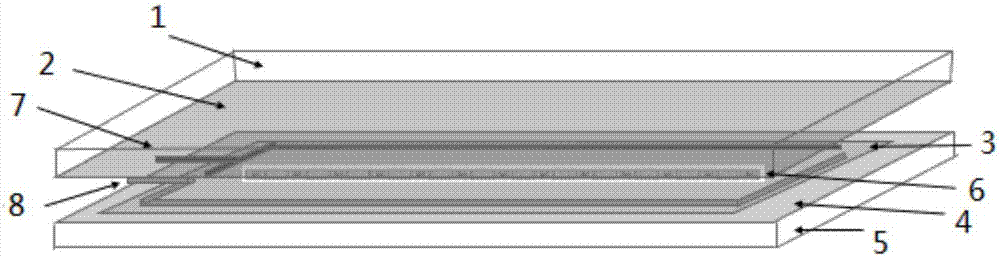

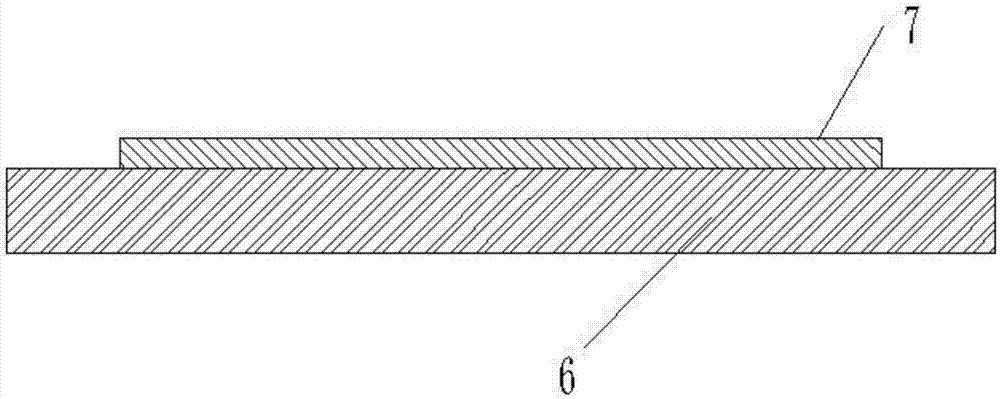

Solar cell module and package method thereof

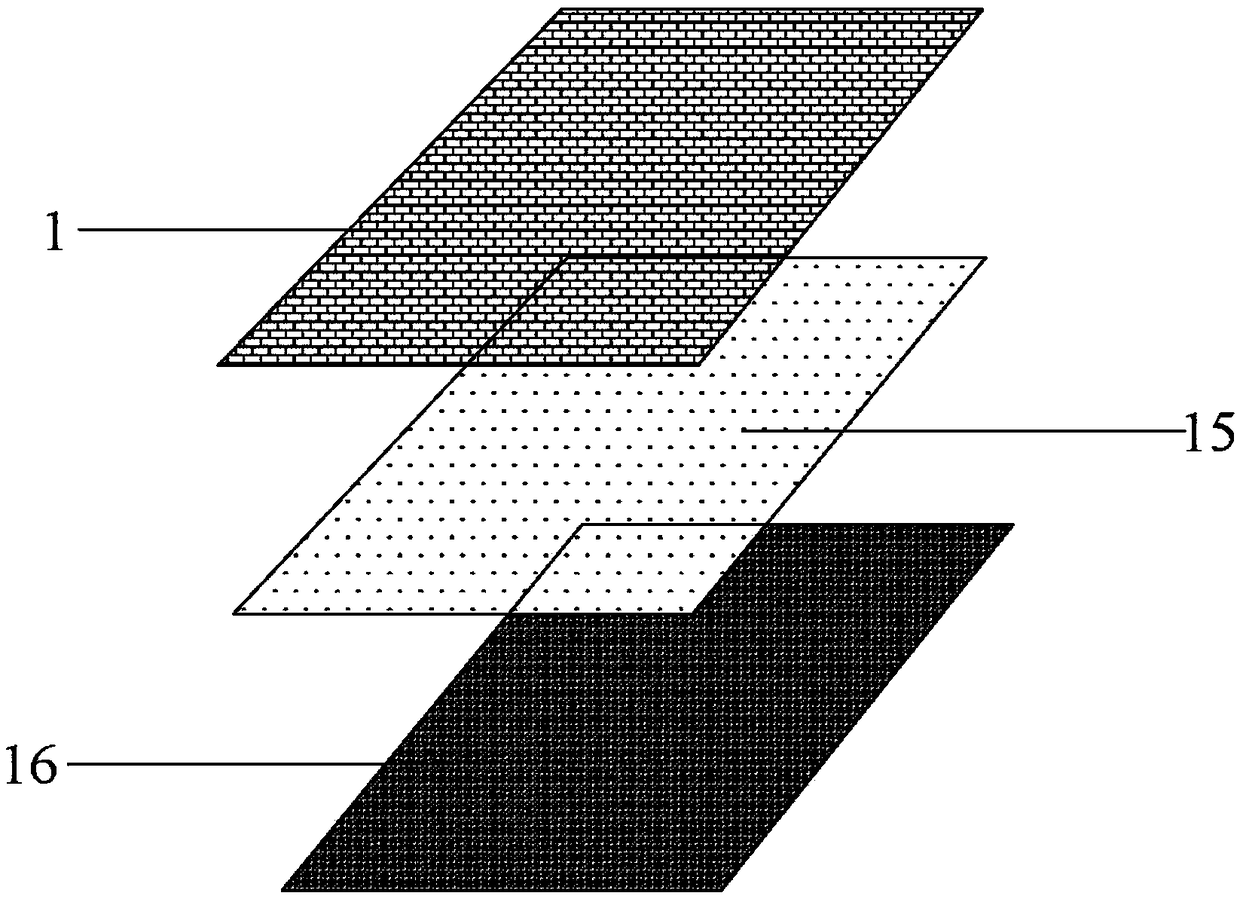

InactiveCN107994089AAvoid wastingSteps to save on croppingPhotovoltaic energy generationSemiconductor devicesLiquid stateEngineering

The invention discloses a solar cell module and a package method thereof, and mainly aims at the problems that areas of a substrate and a front plate are occupied by an existing package method and a battery piece group is small in laying range. The substrate, the battery piece group and the front plate are provided, wherein the battery piece group comprises a first surface and a second surface which are opposite to each other. The package method comprises the following steps of laminating the battery sheet group and the substrate, and arranging liquid-state protection glue between the first surface and the substrate, wherein the protection glue completely covers the first surface; laminating the front plate, the battery piece group and the substrate, and arranging the liquid-state protection glue between the second surface and the front plate, wherein the protection glue completely covers the second surface; and heating and laminating the substrate, the battery piece group, the front plate and the protection glue. By the package method, a butyl adhesive tape is not needed, the laying range of the battery piece group is expanded, moreover, a glue film is not needed to be cut duringprotection glue coating, the protection glue coating is free from the limitation of the specification of the glue film, and the production is relatively flexible.

Owner:BEIJING HANERGY PV TECH CO LTD

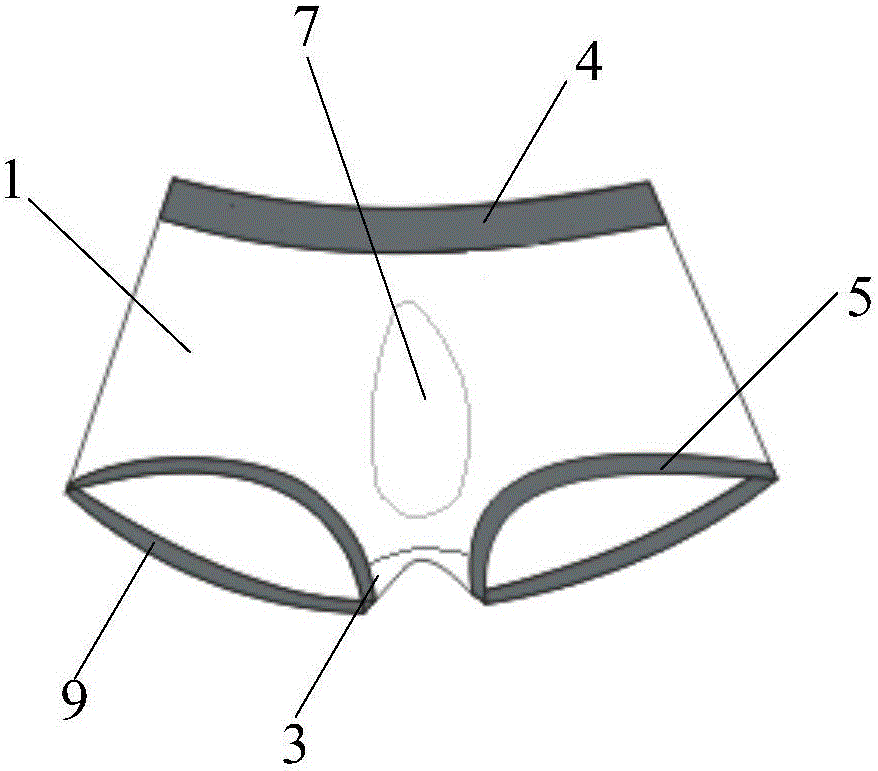

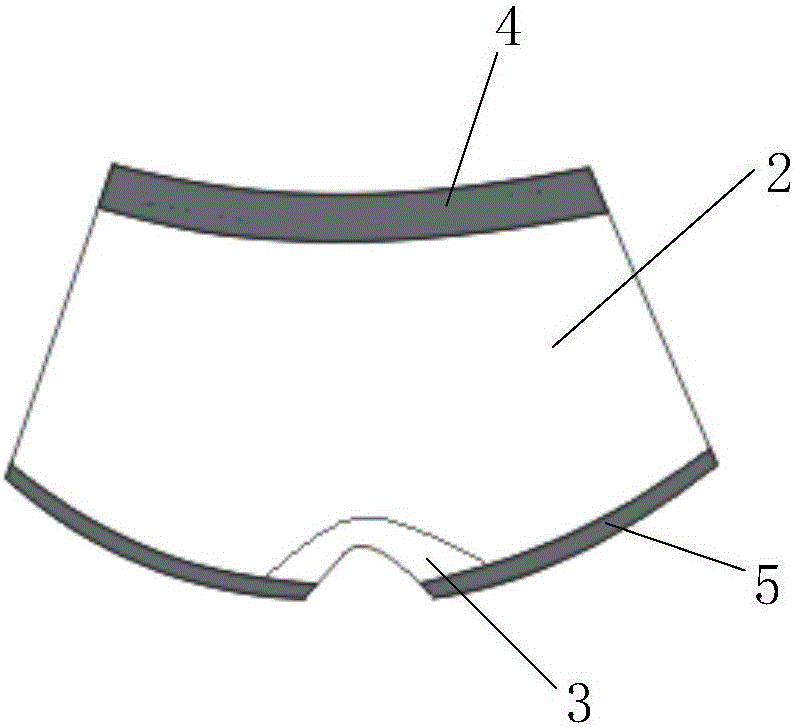

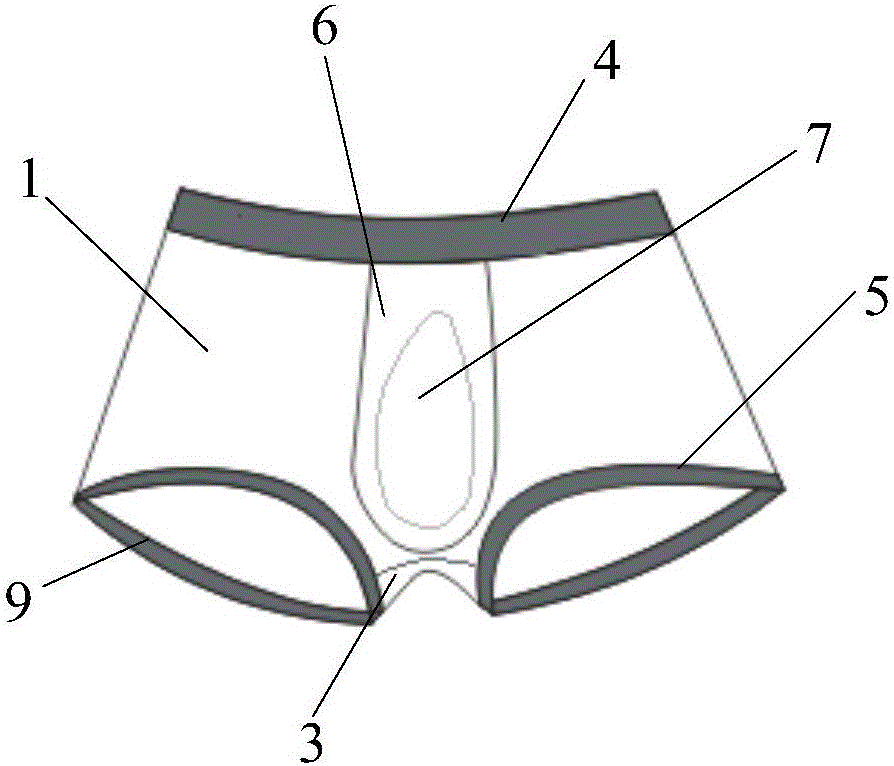

Male underwear and making method thereof

InactiveCN105901779AMeet needsSave cutting processHandkerchiefsBaby linensSilica gelMechanical engineering

The invention discloses male underwear and a making method thereof. The male underwear comprises a front piece, a rear piece and a bottom crotch, the upper edge of the front piece and the upper edge of the rear piece are provided with a waistline portion, the lower edge of the front piece, the lower edge of the rear piece and the two sides of the bottom crotch are provided with leg circumference portions, the middle of the inner side of the front piece is provided with an inner crotch, the inner crotch and the front piece are bound through elastic silica gel, a containing cavity is arranged outside the front piece and the inner crotch in a protruding mode, and the front piece, the rear piece and the bottom crotch are formed by blending an elastic nylon fabric and spandex. The inner crotch is arranged, the containing cavity is arranged on the front piece and the inner crotch, modelling meeting male physiological needs can be formed without sewing two or more front pieces, the clipping process is omitted, the male underwear is convenient to make, the friction feeling cannot be generated, and comfort is improved; the front piece, the rear piece and the bottom crotch are formed by blending the elastic nylon fabric and the spandex, all the pieces of underwear are of the same size, requirements of consumers of different body types can be met, the assorted size phenomenon in the production process is lowered, delivery efficiency is high, and the inventory level is low.

Owner:TENGFEI TECH CO LTD

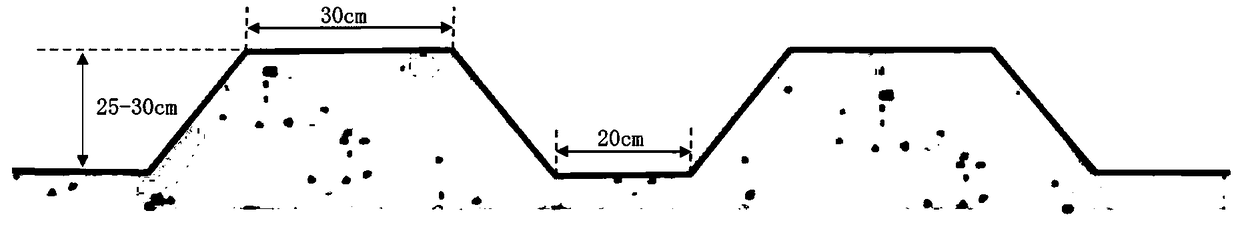

Support method of top plate template in electric ditch whole pouring process

The invention relates to the field of electric construction, in particular to a support method of a top plate template in an electric ditch whole pouring process. The support method comprises the following steps: a soil beam is embedded in a concrete baseplate of a cable ditch; the total height of the soil beam is lower than the upper plane of the concrete baseplate by 2-3 cm; a transverse rib of the soil beam is higher than the bottom surface of the concrete baseplate by 15 cm; then, the upper end of the soil beam is coated with a PVC pipe; the bottom end of the PVC pipe is joined on the transverse rib; a support steel pipe is inserted in the PVC pipe, and coats the soil beam; after the concrete baseplate is poured, the support steel pipe and the PVC pipe are pulled away; and a hole left by the PVC pipe is floated by expansion waterproof mortar. The support method has the following beneficial effects: the support method can save the reinforcement cutting process, saves the cost, is safe and beautiful, guarantees whole pouring of the baseplate with a thickness of 15 cm on the soil beam, and can guarantee water resistance.

Owner:JINAN URBAN CONSTR GRP

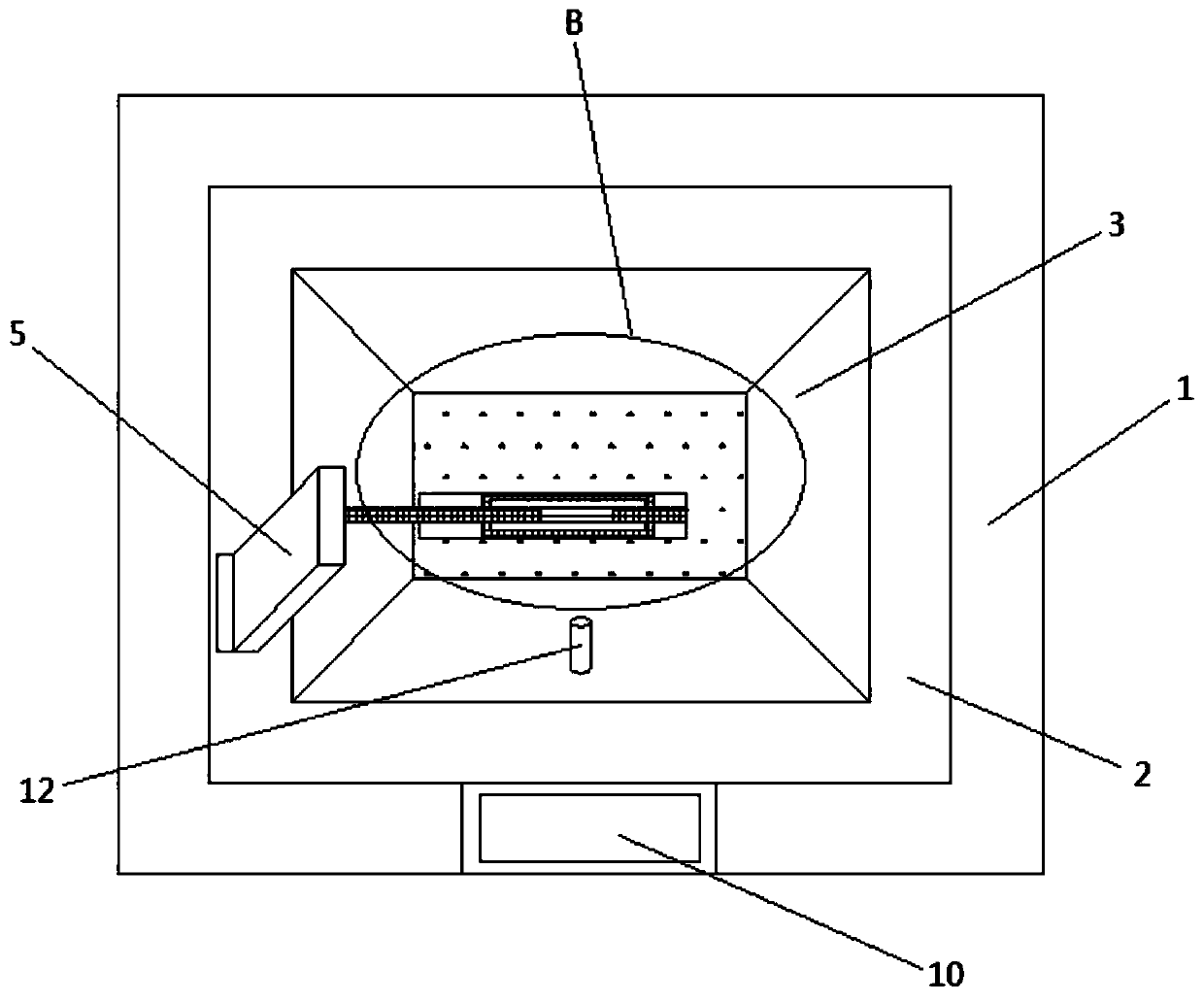

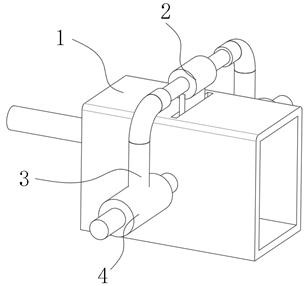

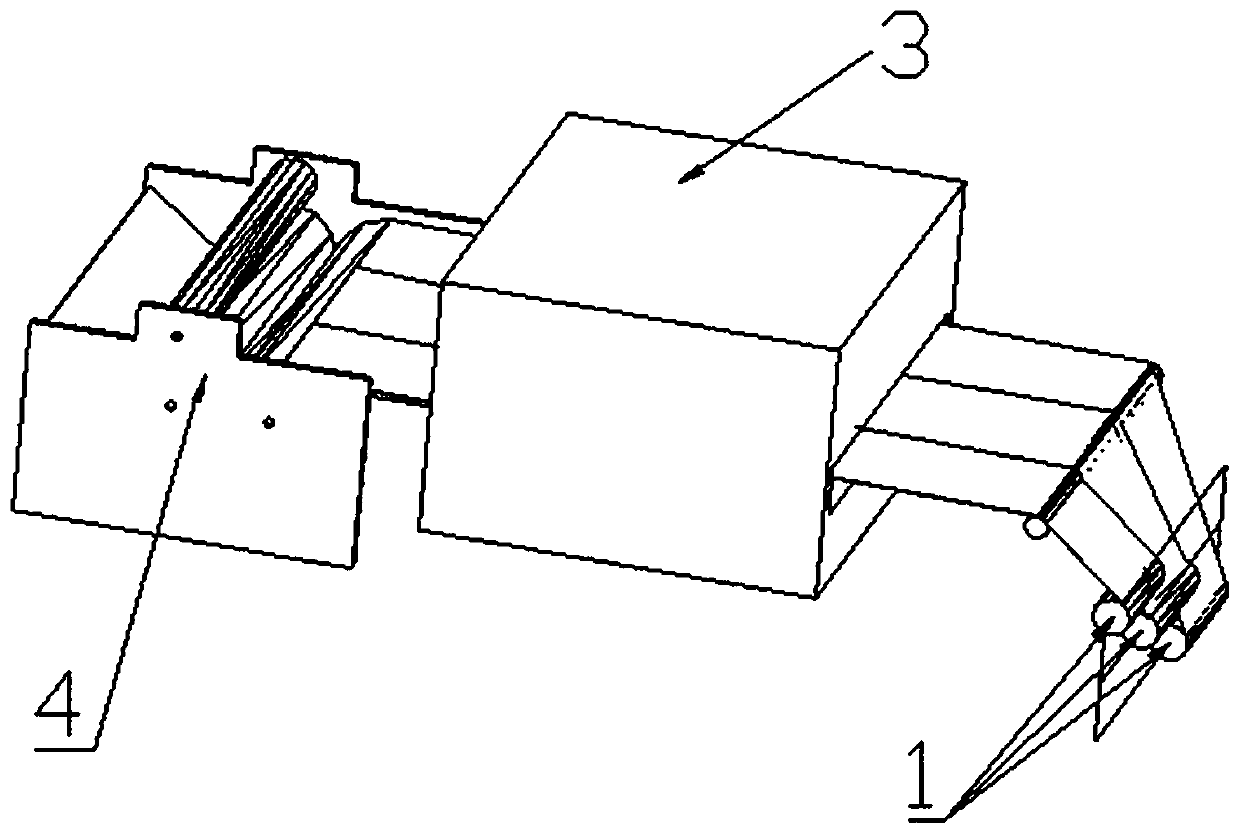

Equipment for manufacturing woven and wound high-strength composite material

The invention discloses equipment for manufacturing a woven and wound high-strength composite material pipe. The equipment comprises a yarn creel, a glue tank, a weaving machine, a pultrusion mould, a traction machine and a feed receiving creel, wherein the glue tank is arranged at a yarn outlet end of the yarn creel; two sides of the glue tank are provided with a front yarn through creel and a rear yarn through creel respectively; the front end of the weaving machine is connected with the rear yarn through rack, and the rear end of the weaving machine is connected with the pultrusion mould; an upper heating plate and a lower heating plate are arranged in the pultrusion mould; the traction machine is arranged at the rear end of the pultrusion mould; and the feed receiving creel is arranged at the rear end of the pultrusion mould. The equipment has a simple structure and can manufacture the woven and wound high-strength composite material pipe which meets requirements; and the composite material pipe is widely applicable to various tent racks.

Owner:ARCHITECTURAL ENG INST GENERAL LOGISTICS DEPT P L A +1

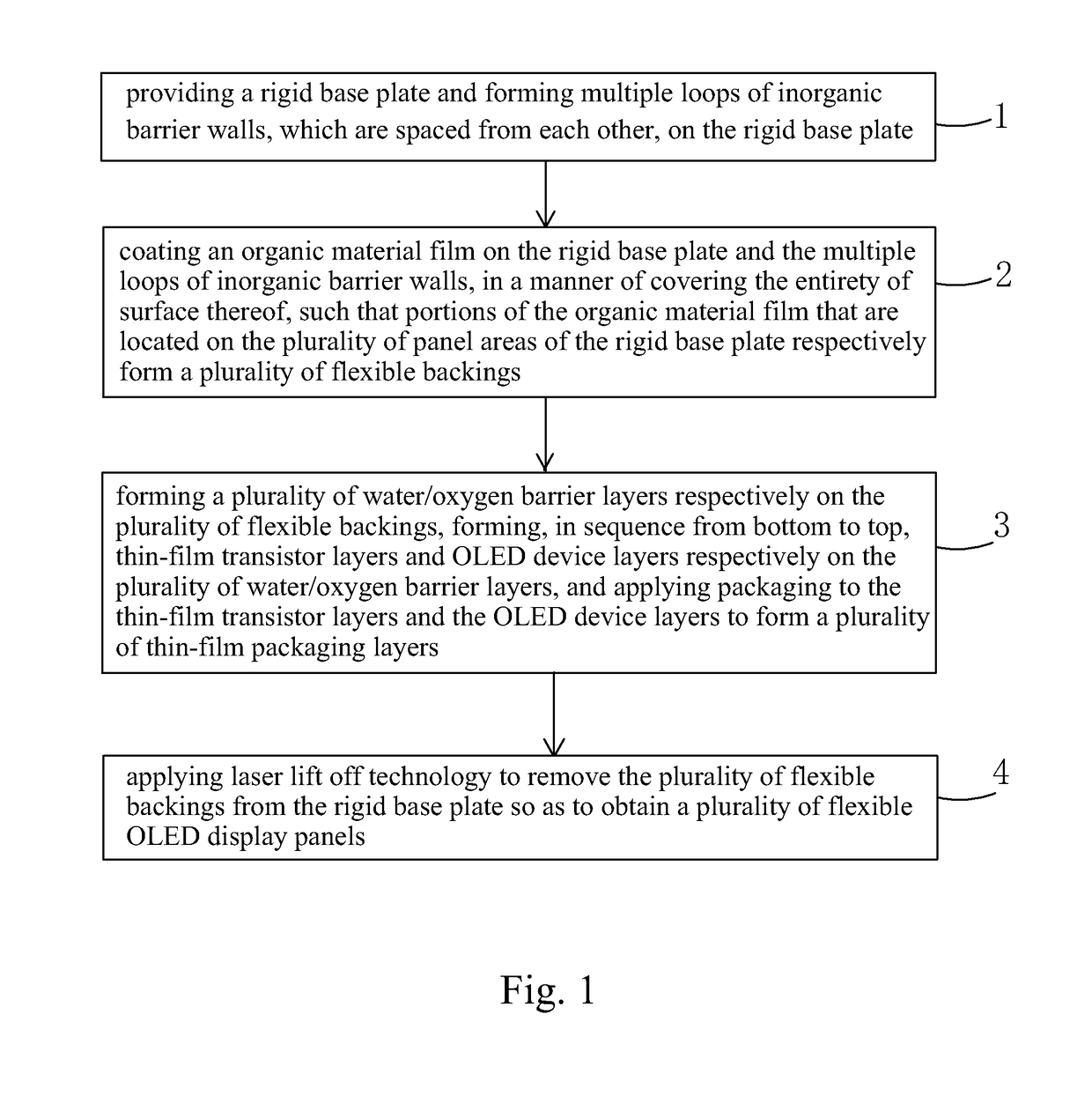

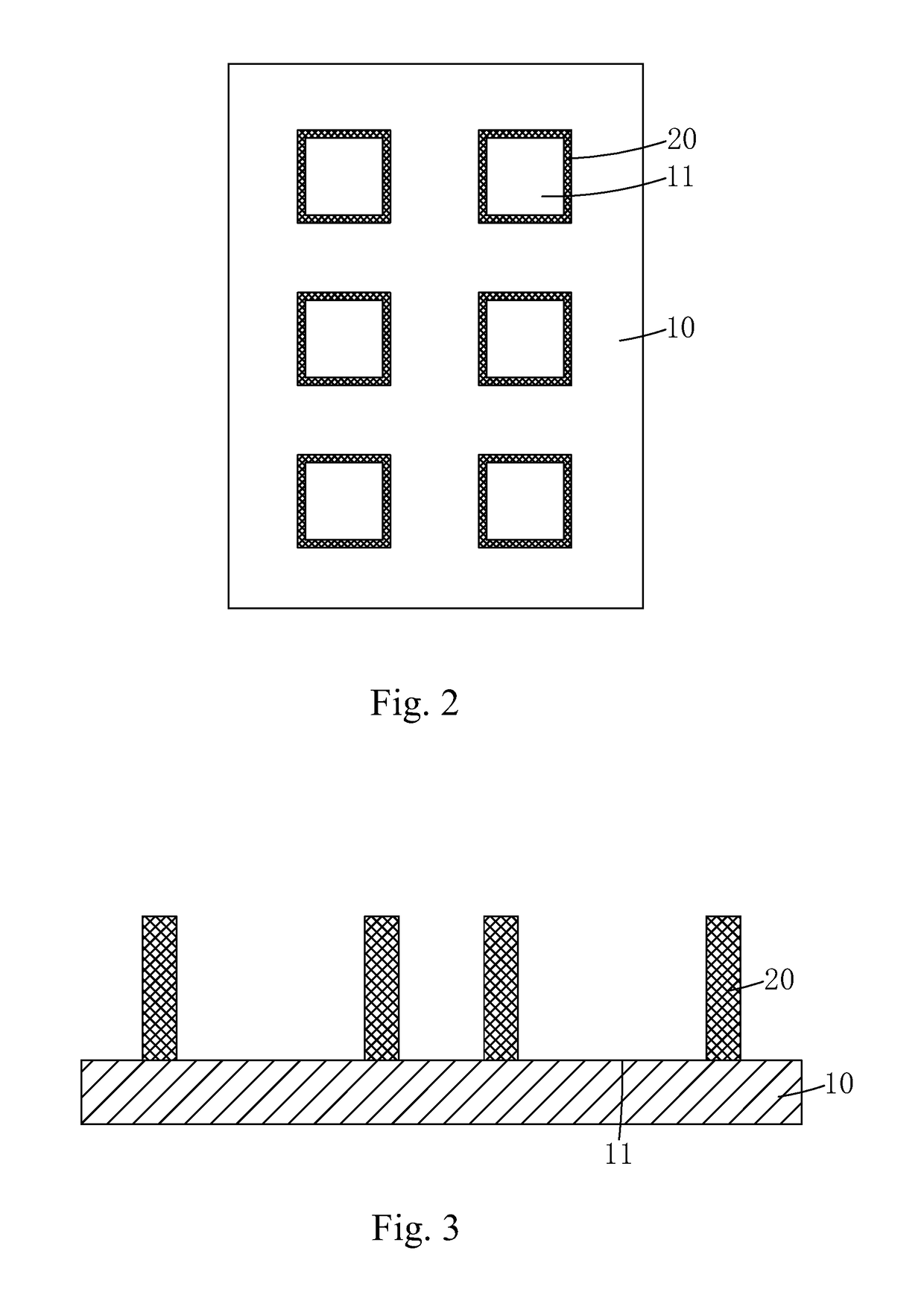

Manufacturing method of flexible OLED display panel

ActiveUS20180198094A1Lower purchase costReduce manufacturing costFinal product manufactureSolid-state devicesState of artEngineering

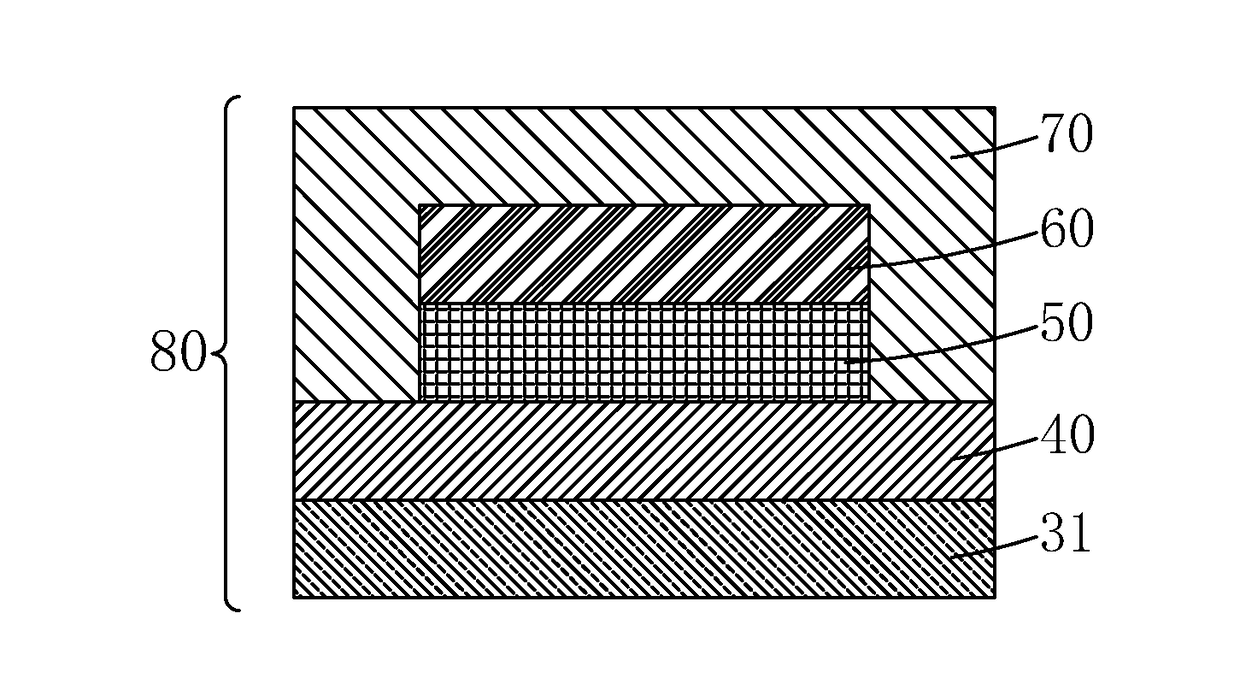

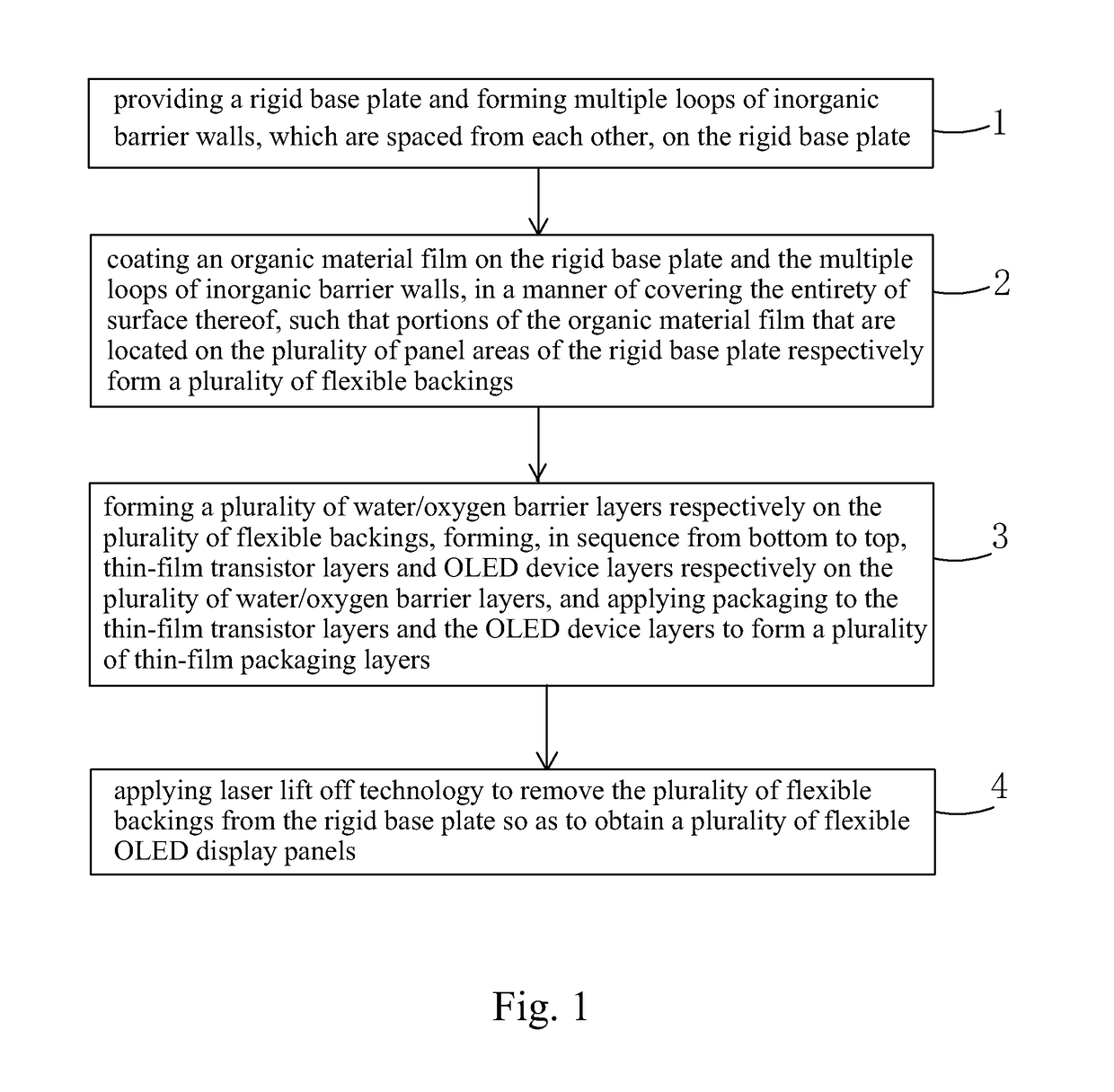

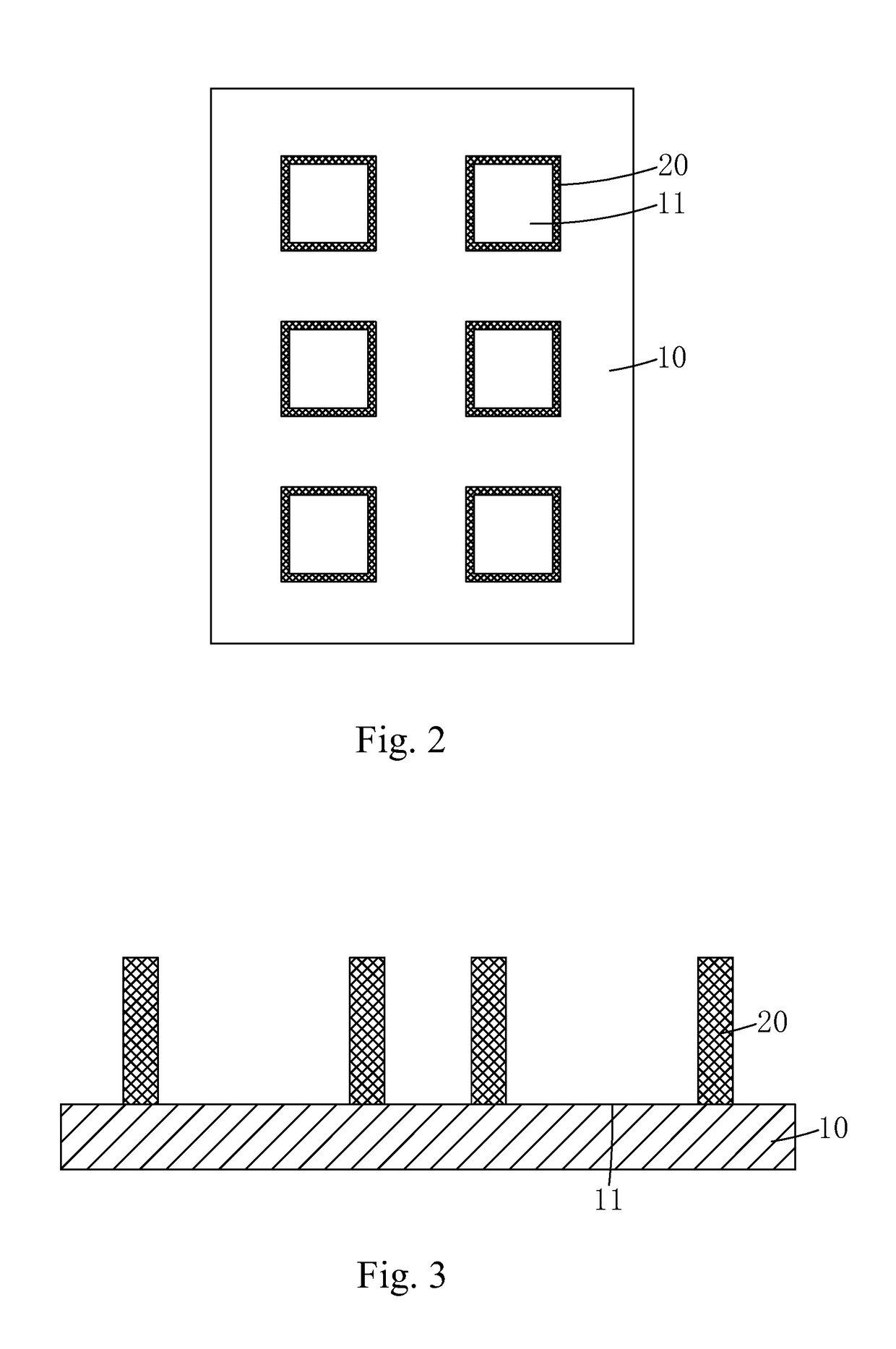

The present invention provides a manufacturing method of a flexible OLED display panel, in which multiple loops of inorganic barrier walls are first formed on a rigid base plate such that the multiple loops of inorganic barrier walls respectively and circumferentially encloses a plurality of panel areas on the rigid base plate so that when an organic material film is then coated on the rigid base plate and the multiple loops of inorganic barrier walls in a manner of covering the entirety of surface thereof, the multiple loops of inorganic barrier walls provide an effect of division to allow a plurality of flexible backings to be respectively formed on the plurality of panel areas of the rigid base plate. Afterwards, a laser lift off technique is applied to remove the plurality of flexible backings from the rigid base plate to thus obtain a plurality of flexible OLED display panels. Compared to the prior art, the present invention saves a process of using a laser cutting machine to simultaneously cut the organic material film and the rigid base plate and thus saves the cost of purchasing the laser cutting machine and also save one round of laser cutting operation to thereby reduce the manufacturing cost of a flexible OLED display panel.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

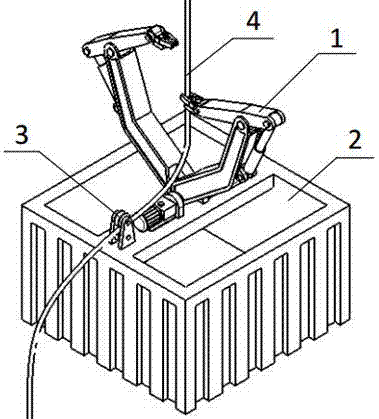

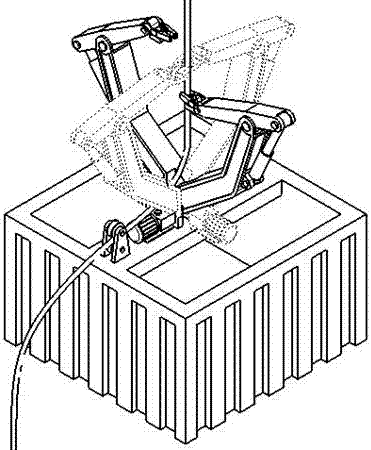

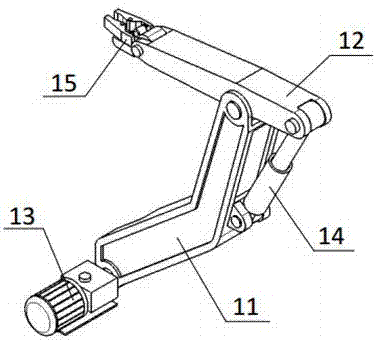

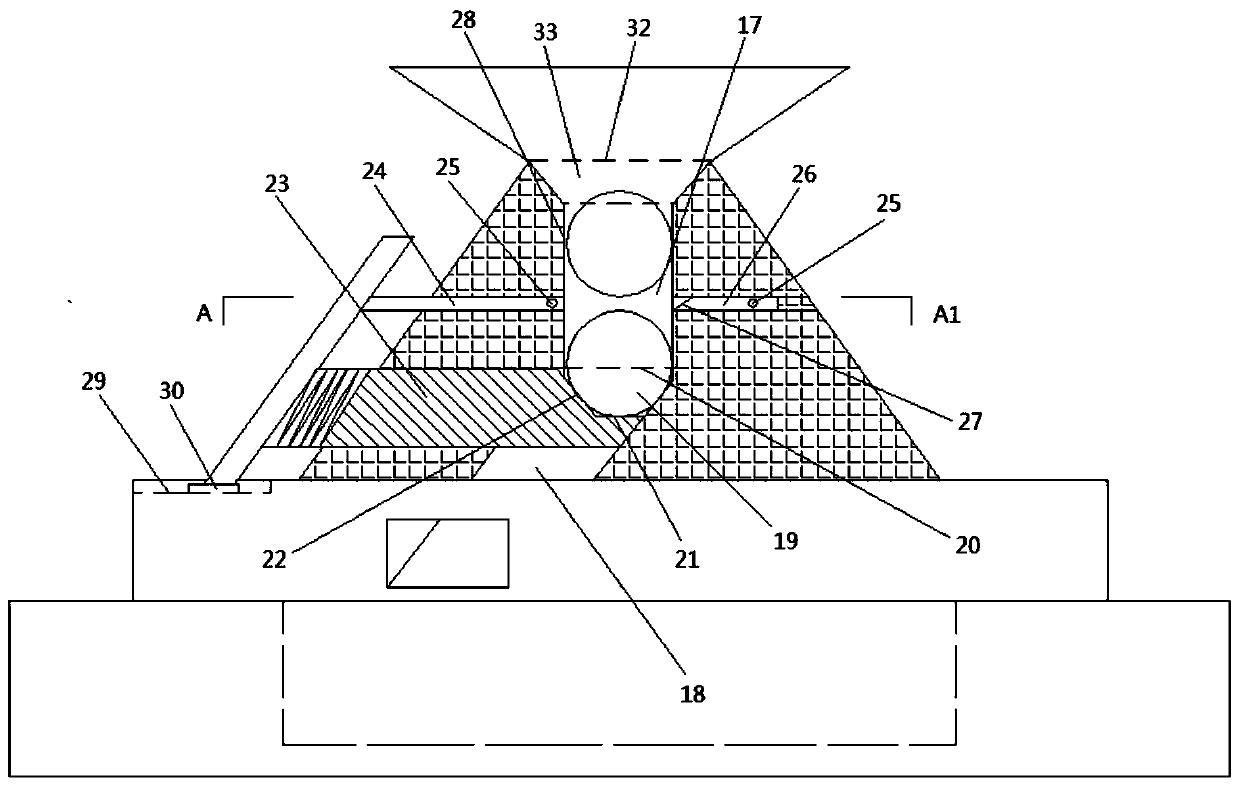

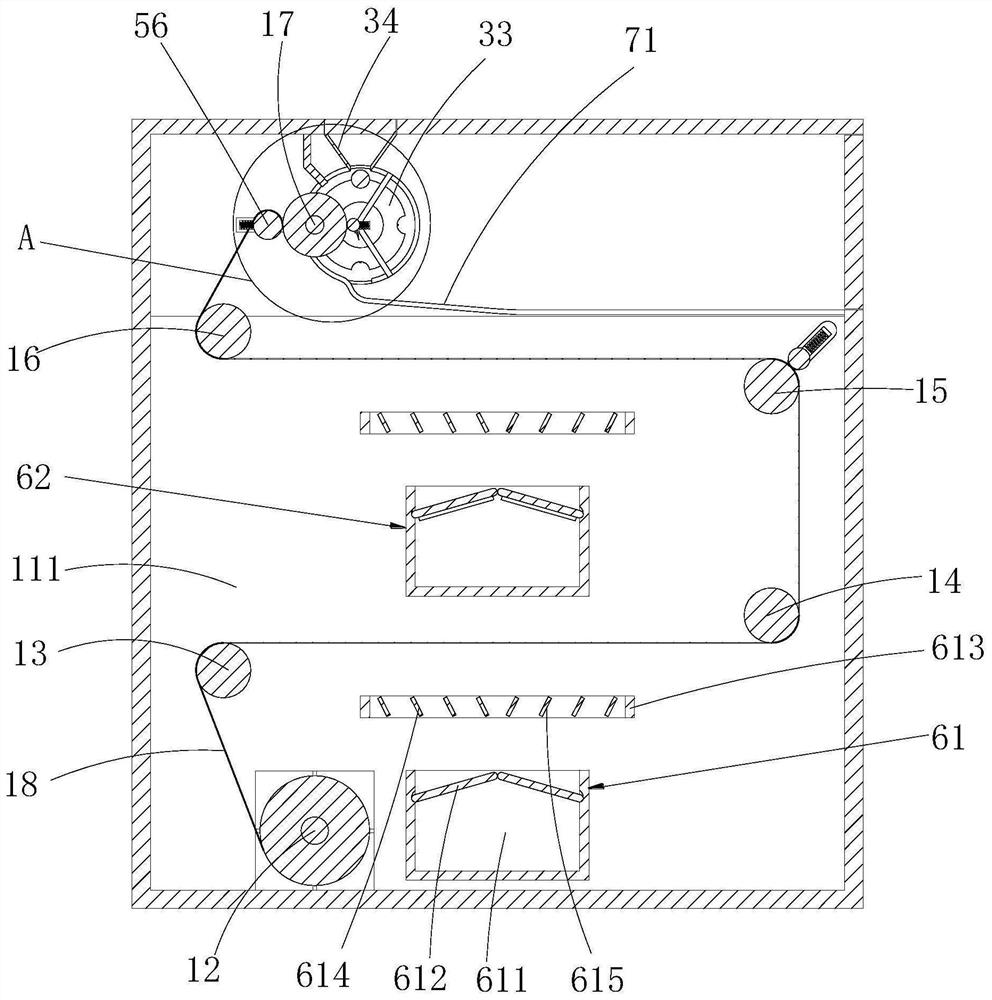

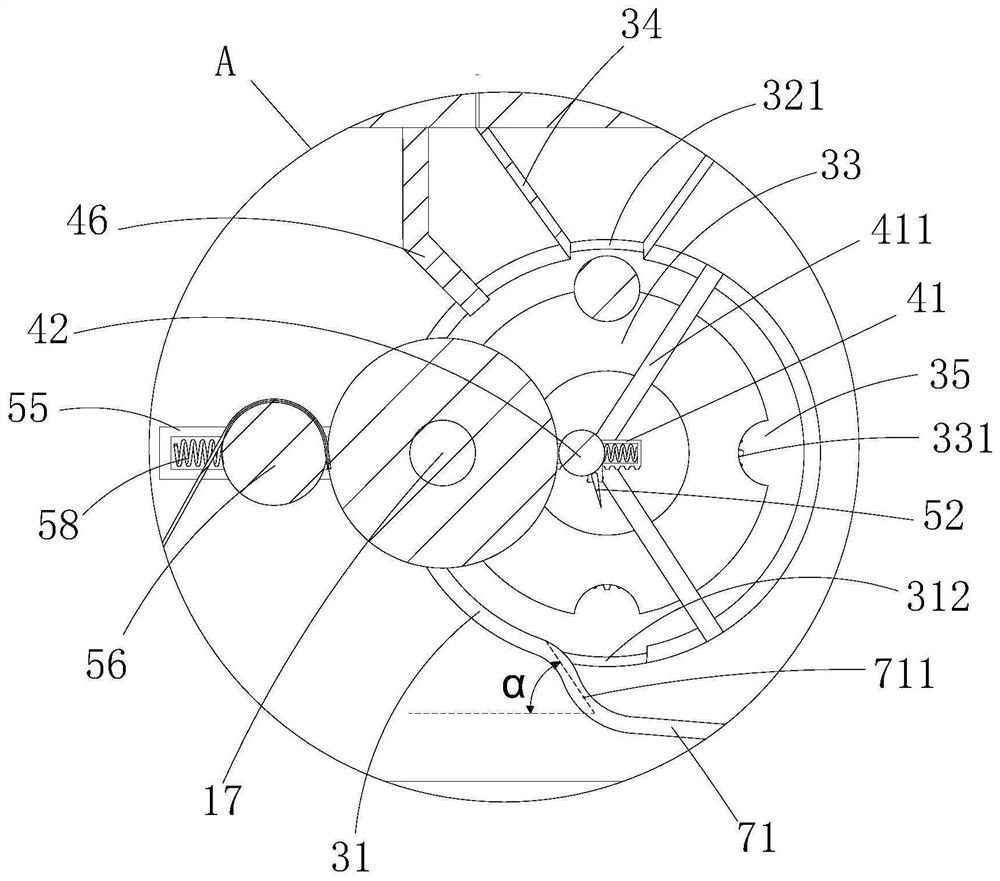

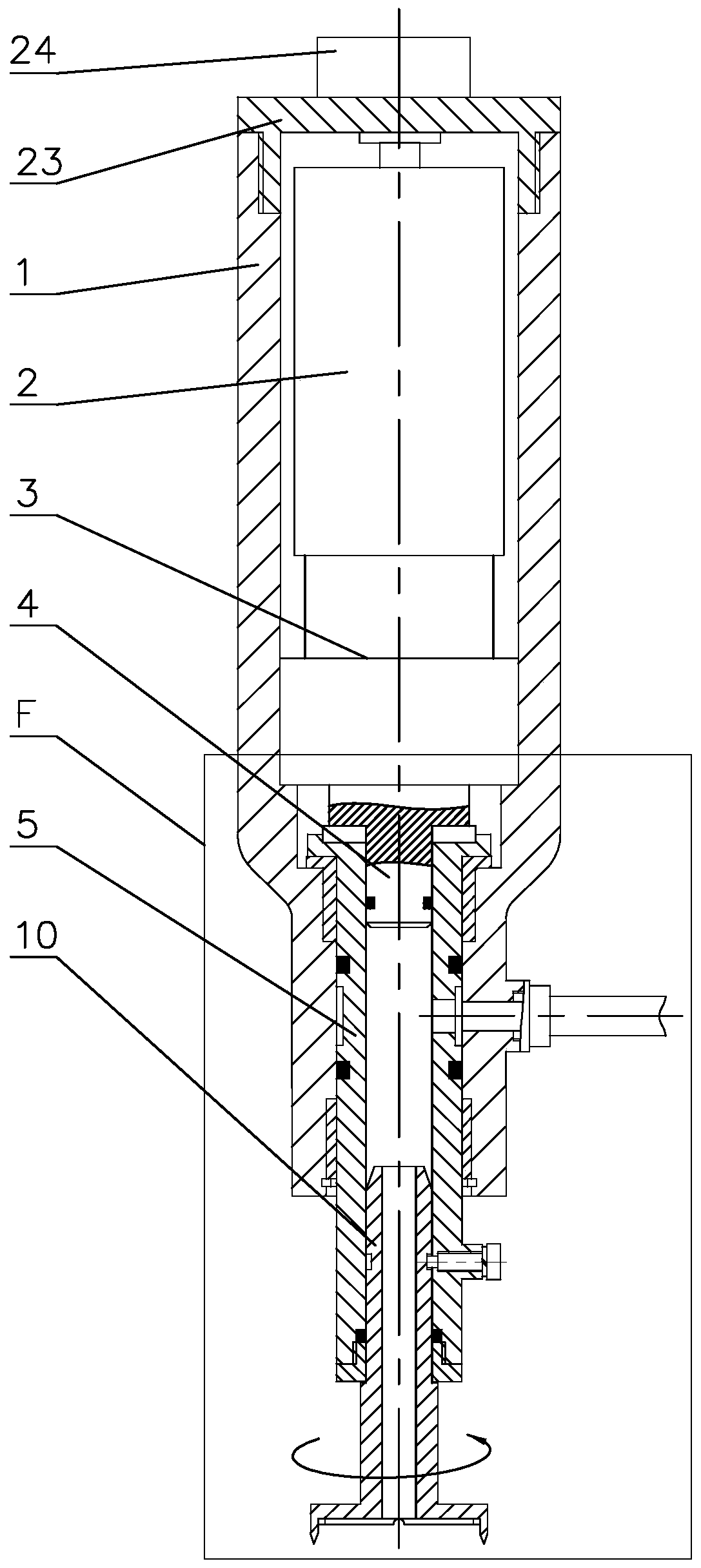

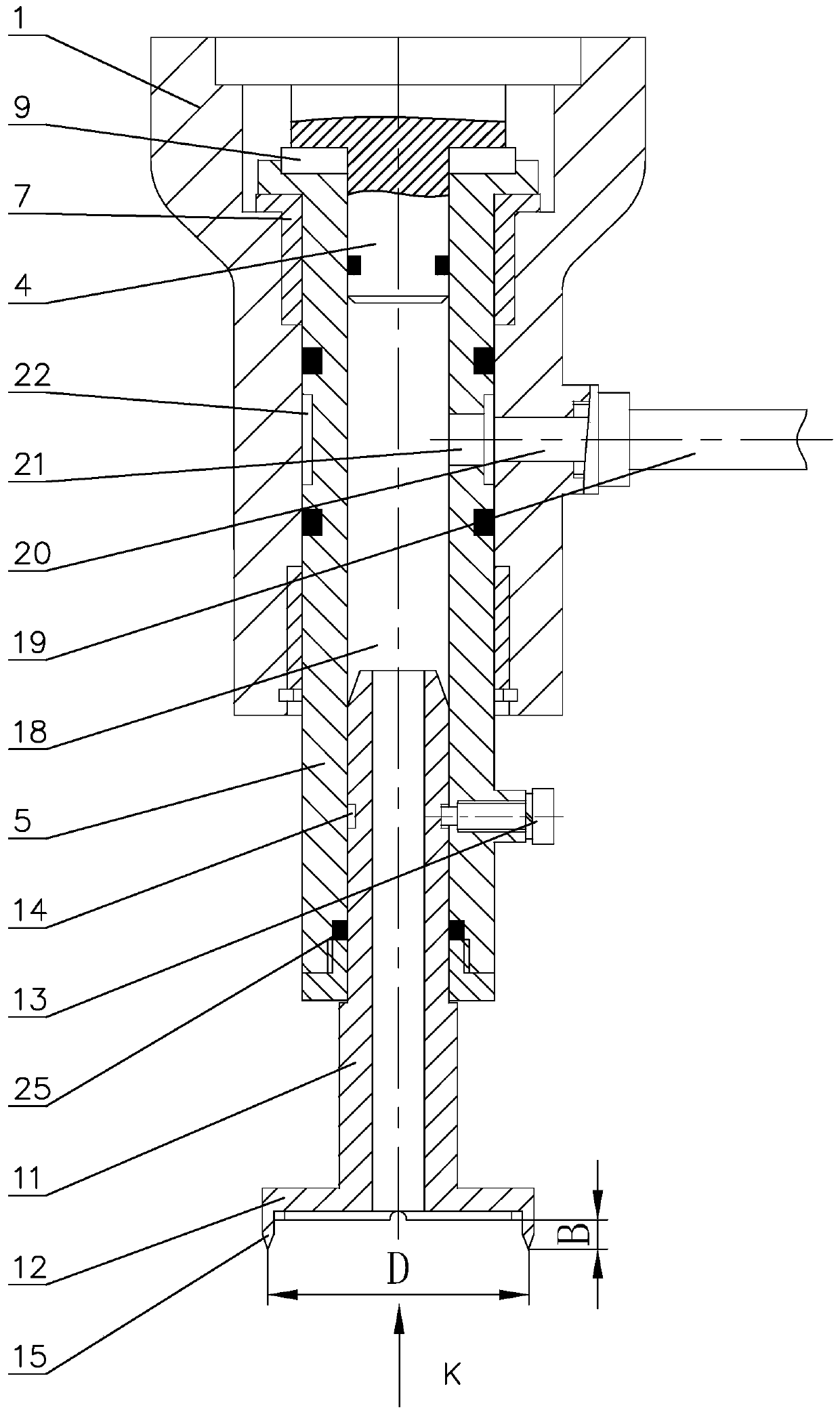

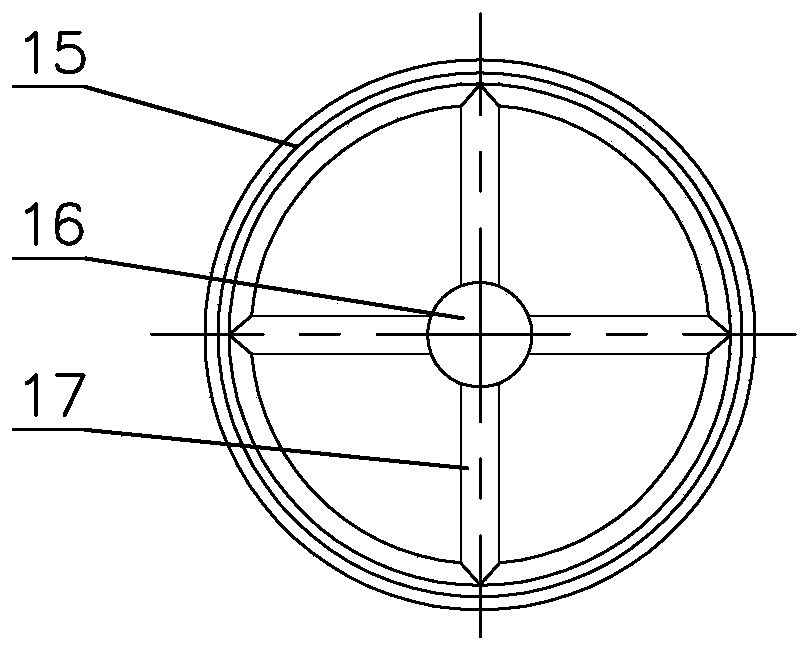

Climbing-along-rope type energy-saving lifting device for deep-sea mining

ActiveCN107288639AEasy to operateImprove mining efficiencyMineral miningVehiclesHydraulic cylinderDeep sea mining

The invention relates to a climbing-along-rope type energy-saving lifting device for deep-sea mining. The energy-saving lifting device mainly comprises a double-arm type rapid climbing mechanism, a material containing tank, a guide pulley and a high-strength rope. The double-arm type rapid climbing mechanism is mainly used for lifting seabed minerals and composed of multiple sets of mechanism arms, wherein each set including the corresponding two mechanism arms. Root arm bodies of the mechanism arms are driven by motors, the tail ends of the root arm bodies are hinged to intermediate beams on the top of the materiel containing tank, and the motors are mounted at the tail ends of the root arm bodies; front arm bodies are driven by hydraulic cylinders, the middle sections of the front arm bodies are hinged to the front ends of the root arm bodies, one ends of the hydraulic cylinders are hinged to the middle sections of the root arm bodies, and the other ends of the hydraulic cylinders are hinged to the tail ends of the front arm bodies. Rotatable clamping devices are mounted at the front ends of the front arm bodies for clamping the high-strength rope during climbing. The multiple sets of mechanism arms orderly and alternately operate during climbing, and thus the seabed minerals are lifted rapidly. According to the climbing type lifting scheme, energy-saving and economical properties are high, the implement process is simple and convenient, the mining efficiency of the seabed minerals is improved, and the mining cost of the seabed minerals is reduced.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

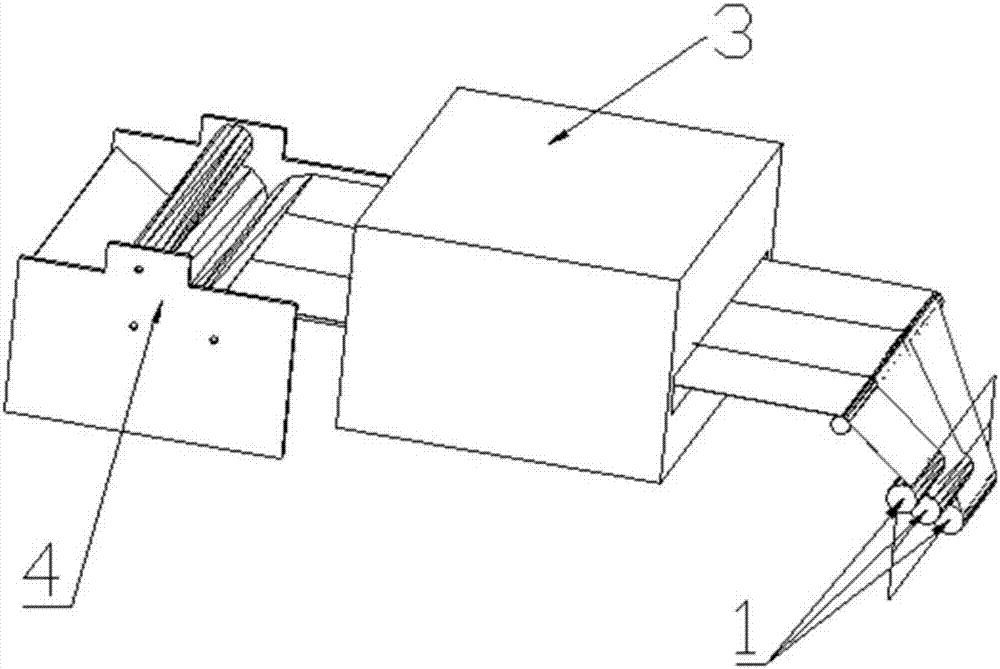

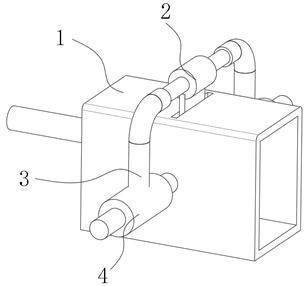

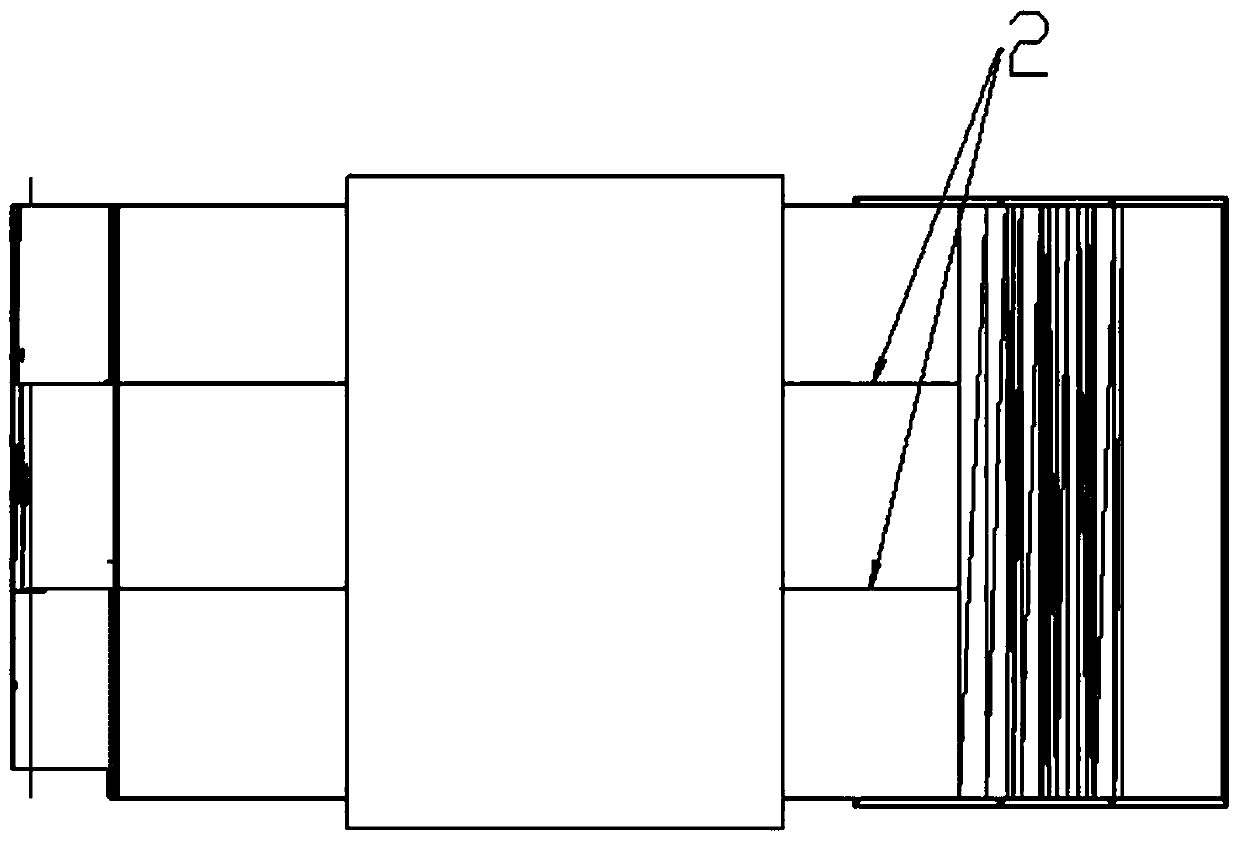

A battery polar plate coating system and method

InactiveCN106910868AEfficient coatingReduce processElectrode collector coatingAdhesiveCoating system

A battery polar plate coating system and method are disclosed. The system includes a coating machine head (4), a drying oven (3) and a winding device (1). The winding device is provided with N independent winding modules, with the N being an integer and not less than 2. The coating machine head is used for coating a foil belt with coating slurry (6). The foil belt is formed by adhering N foil subsidiary bets through an adhesive (2). Adjacent two foil subsidiary bets are expanded at the width direction of the foil belt and are partially overlapped. After the foil belt passes through the drying oven (adhesive force of the adhesive is lost due to heating functions), N polar plates are separated and are respectively wound by the N independent winding modules. The system and the method are easy to implement and the coating efficiency is high.

Owner:SHENZHEN SHENG ENERGY TECH CO LTD

Round tablet slitting device

The invention discloses a round tablet slitting device, and relates to the technical field of medical instruments. The round tablet slitting device comprises a base, a mounting plate, a solid block, atablet hopper, a pull plate, a slide plate, a guide box, a rectangular tablet guide passage, a trapezoidal positioning tablet hopper and a cutter mechanism. When the round tablet slitting device is used, only a cutter mechanism needs to be pressed to cut a round tablet into two halves, then the pulling plate is pulled, and the cut round tablet can slide into a tablet collecting groove from a tablet outlet sliding groove. Meanwhile, after the round tablets on the upper portion are isolated and the pulling plate is loosened, communication of a rectangular tablet guiding channel is achieved, a trapezoidal positioning tablet hopper restores, a round tablet on the upper portion are rapidly positioned, and then the cutting knife mechanism is pressed to cut the round tablet again. The round tablet slitting device is simple in structure, is convenient to use, can achieve continuous slitting of round tablets and is high in slitting efficiency.

Owner:THE AFFILIATED HOSPITAL OF QINGDAO UNIV

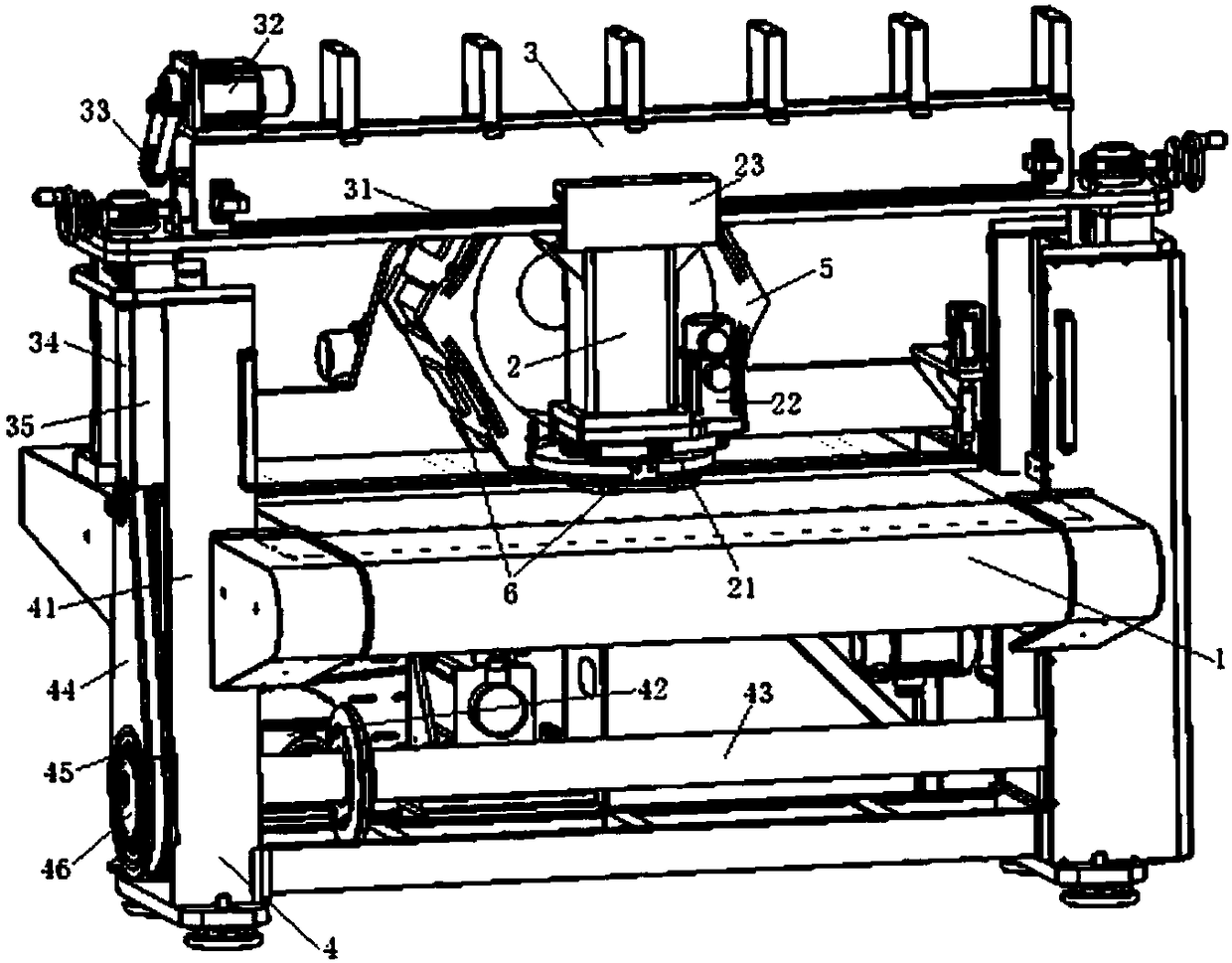

On-line slitting and winding device for wet-process diaphragm of lithium battery

PendingCN109987443ASave cutting processIncrease productivityArticle deliveryWebs handlingEngineeringMechanical engineering

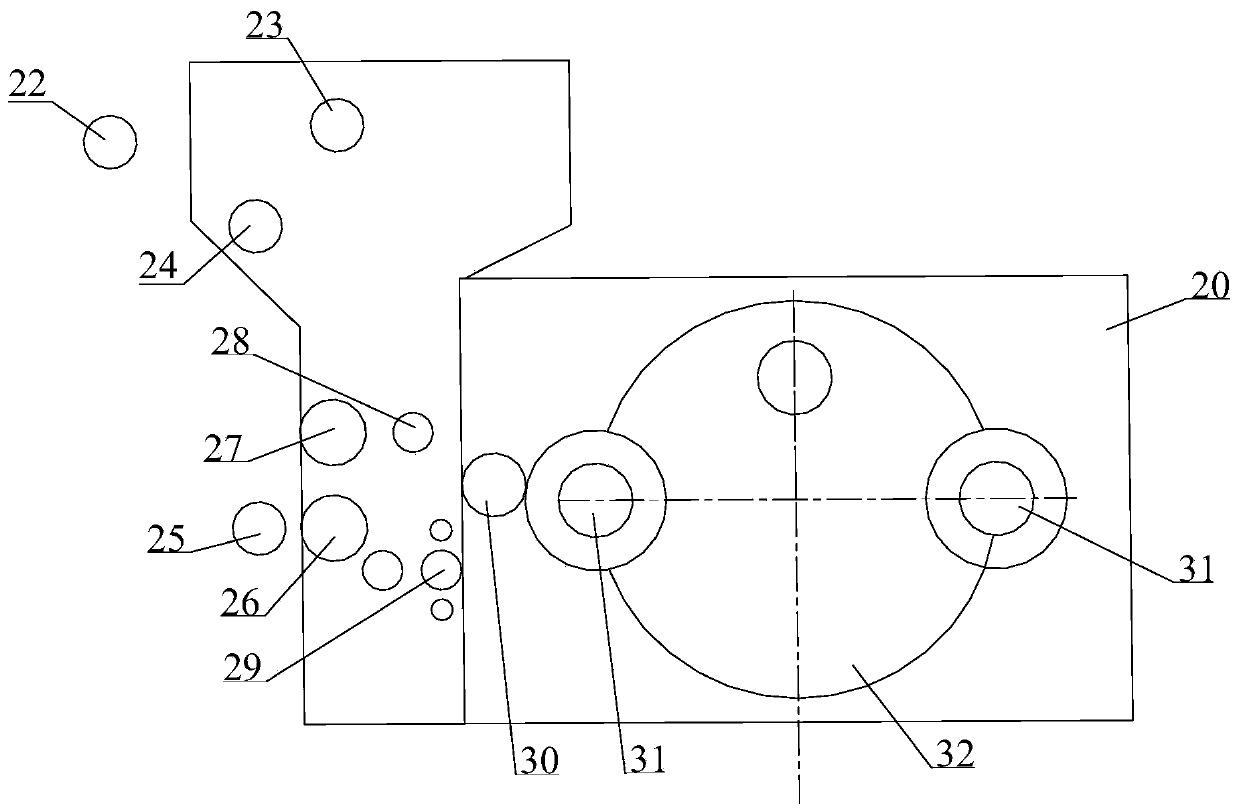

The invention discloses an online slitting and winding device for a wet-process diaphragm of the lithium battery. On-line separation of the diaphragm can be realized as a small volume, and the production plan can be flexibly adjusted flexibly. The online slitting and winding device for a wet-process diaphragm of the lithium battery comprises a slitting mechanism and at least two winding mechanisms; the slitting mechanism comprises a rolling roller which is sequentially arranged along a membrane penetrating path of the diaphragm, a first guide roller, a second guide roller and a slitting roller, wherein the slitting roller is provided with a cutter; and each winding mechanism comprises a driven fog surface roller which is sequentially arranged along a membrane penetrating path of the separated diaphragm, a first driven mirror roller, a driving roller, a second driven mirror roller, a floating roller, a guide roller and a winding roller.

Owner:SUZHOU GREEN POWER NEW ENERGY MATERIALS CO LTD

A clothing single-sided molding method and 3D printing device

ActiveCN105984138BEliminate the need for suturesElimination of melt spinning processAdditive manufacturing apparatusAdditive manufacturing with liquidsWater solubleHot melt

The invention discloses a single-face forming method of clothing and a 3D printing device and belongs to the field of FDM-type 3D printing. The device includes a long-distance multi-hole printing head and a double-row-hole filling printing head, and the method is a single-face forming method. The method includes the steps of: printing a cloth fabric layer with the long-distance multi-hole printing head with an edge strip at a joint position remained; printing a water-soluble material interlayer with the double-row-hole filling printing head or covering the cloth fabric layer with a separation board, folding-up the edge strip, and printing a cloth fabric layer with the long-distance multi-hole printing head; holt-melting the edge strip with the third cloth fabric layer together, and finally dissolving the water-soluble material interlayer or removing the separation board to form clothing. The invention achieves production of a clothing and wearing product through 3D printing technology. The method saves cost and reduces processing time and can be used for producing the clothing being more flexible in styles, and can replace a part of conventional process technologies for producing the clothing and wearing product.

Owner:CHANGZHOU DONGKE ELECTRONICS TECH CO LTD

Evaporation production process of polyester ultrathin film

InactiveCN114231907AReduce processImprove processing efficiencyVacuum evaporation coatingSputtering coatingPolyesterPolymer science

The invention discloses an evaporation production process of a polyester ultrathin film. The evaporation production process comprises the following steps: S1, carrying out base film penetrating work; a base film passes through a film passing path formed by the unwinding roller, the first transition roller, the first cooling roller, the second transition roller, the second cooling roller and the winding roller to achieve film penetrating, and film penetrating preparation work is completed. S2, vacuumizing a coating chamber in the case; s3, the winding device is started, and film feeding is started; s5, a metal aluminum thermal evaporation process: a first coating device works on one side of the base film to form an aluminum film, and a second coating device forms an aluminum film on the other side of the base film; s6, a split charging device is used for transferring the winding roller wound with the thin film with the set thickness out of the winding position, and meanwhile the winding roller to be wound is switched to the winding position; the aluminum films can be plated on the two faces of the base film at the same time through one-time film feeding, the working procedures are reduced, and the machining efficiency is improved. And the thin film is slit in the winding process, so that the special slitting procedure is omitted, and the production efficiency is improved.

Owner:NINGBO GREAT SOUTHEAST WAN XIANG SCI & TECH

Manufacturing method of flexible OLED display panel

ActiveUS10153462B2Reduce purchasing costsReduce manufacturing costFinal product manufactureSolid-state devicesState of artEngineering

The present invention provides a manufacturing method of a flexible OLED display panel, in which multiple loops of inorganic barrier walls are first formed on a rigid base plate such that the multiple loops of inorganic barrier walls respectively and circumferentially encloses a plurality of panel areas on the rigid base plate so that when an organic material film is then coated on the rigid base plate and the multiple loops of inorganic barrier walls in a manner of covering the entirety of surface thereof, the multiple loops of inorganic barrier walls provide an effect of division to allow a plurality of flexible backings to be respectively formed on the plurality of panel areas of the rigid base plate. Afterwards, a laser lift off technique is applied to remove the plurality of flexible backings from the rigid base plate to thus obtain a plurality of flexible OLED display panels. Compared to the prior art, the present invention saves a process of using a laser cutting machine to simultaneously cut the organic material film and the rigid base plate and thus saves the cost of purchasing the laser cutting machine and also save one round of laser cutting operation to thereby reduce the manufacturing cost of a flexible OLED display panel.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

Continuous numerical control pipe bending machine

ActiveCN113617901ASolve the dead angle problemPrevent looseningMetal-working feeding devicesShaping safety devicesNumerical controlClassical mechanics

The invention belongs to the field of pipe machining, and particularly relates to a continuous numerical control pipe bending machine which comprises a machining box, wherein a cutting groove is formed in the top of an inner cavity of the machining box, a vertical cutting blade is slidably connected to the top of the inner cavity of the machining box through the cutting groove, a movable sleeve arm is fixedly connected to the top end of the vertical cutting blade, auxiliary shaft rods are slidably connected to the two ends of the inner wall of the movable sleeve arm correspondingly, the rear ends of the auxiliary shaft rods are fixedly connected to the front face of the outer surface of the machining box, and thrust motors are fixedly connected to the front faces of the outer surfaces of the auxiliary shaft rods. Due to the fact that the steel pipe is bent through the torque device, the steel pipe can be machined into an annular pipe and even a bent pipe with a more special angle, the shape and the bending angle of the steel pipe are more than those of a steel pipe machined through a common pipe bending machine, and the machined pipe body flies out of the torque device under the inertia effect and is thus thrown into a collecting device beside, to complete automatic collection of the steel pipe, so that the device has continuity.

Owner:南通驰连机械有限公司

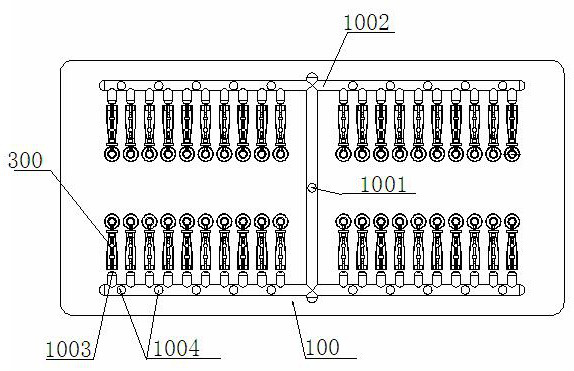

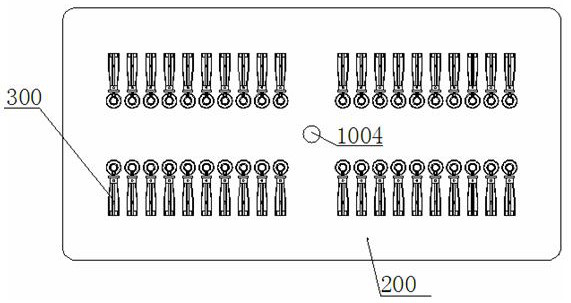

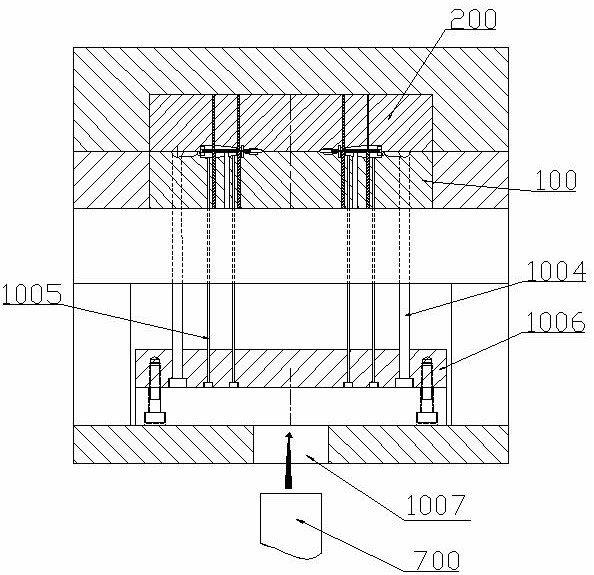

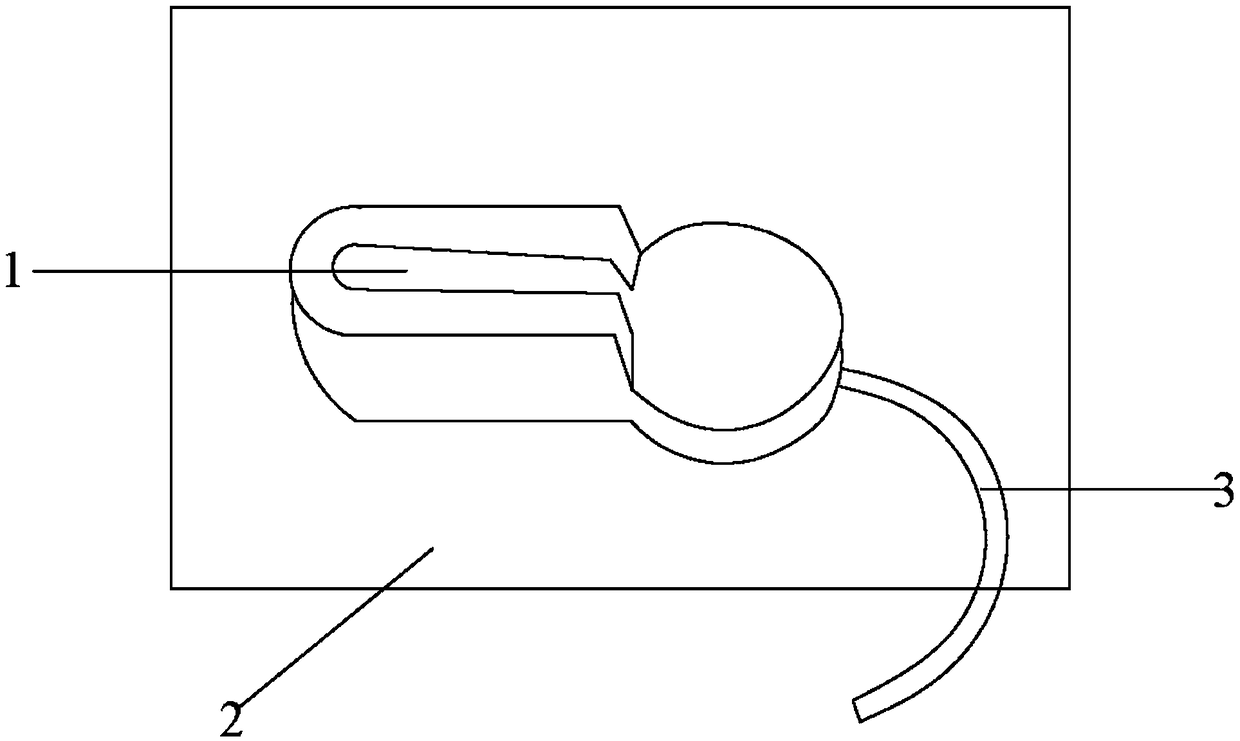

Blood collection needle injection mold and blood collection needle injection technology

PendingCN111958918AReduce horizontal forceSolve the limitation of up and down displacementCoatingsBlood collectionBlood lancet

The invention relates to the technical field of blood collection needle production and discloses a blood collection needle injection mold and a blood collection needle injection technology. The injection mold is formed by folding an upper mold and a lower mold. At least one mutually corresponding mold cavity is set on the upper mold and the lower mold. Each mold cavity comprises a needle cap cavity and a needle handle cavity which are communicated. A gate and a main runner are set on the lower mold. The gate is communicated with the mold cavity. An injector nozzle communicated with the main runner is set on the upper mold. The gate is located at one end of the needle handle cavity away from the needle cap cavity. A preset included angle is formed between the gate and a plane where the tailend of the needle handle cavity is in. A connection point of the gate and the needle handle cavity deviates from a needle body. The injection technology comprises the steps of placing needles, folding the molds, injecting plastic and opening the molds. According to the injection mold and the injection technology, through modification of a gate location and through adjustment of a plastic injection direction, the problem that an injection molded blood collection needle body penetrates into skin insufficiently and pain is increased due to the fact that the injection molded blood collection needle body is liable to translate in a needle handle is solved. The injection technology is carried out through utilization of the corresponding injection molds, so injection technology steps such as cutting and manual checking are reduced, and the cost is reduced.

Owner:HUAIAN TIANDA MEDICAL INSTR

A kind of chrysanthemum cultivation method

InactiveCN105660127BShorten the timeGuarantee that the seedlings are full and strongFlowers cultivationCultivating equipmentsShootChrysomya

The invention relates to a cuttage-free chrysanthemum cultivation method which mainly comprises the following steps: preparing cutting shoot stock plants, preparing a land and making small pieces of land, making trenches in the land, collecting cutting shoots, planting in bottoms of the trenches, covering and uncovering a film, flattening the trenches, and hilling. By adopting the cuttage-free chrysanthemum cultivation method, the requirements that the chrysanthemum reproduction process is simplified, the cost is reduced and the production time is shortened can be met; unique methods are used to integrate a cuttage stage and a transplanting stage into one process in the chrysanthemum planting process; as chrysanthemum cutting shoots without roots are directly planted in the land, the problems that the chrysanthemum seedling growth period is long, the transplanting seedling rejuvenation period is long and mechanical injury can be caused in the transplanting process can be solved, not only is time saved, but also the whole chrysanthemum seedlings can grow well; the planting process is convenient, simple and economic, a great deal of time can be saved, and the cuttage-free chrysanthemum cultivation method is a simple and efficient chrysanthemum cultivation method.

Owner:QINGDAO AGRI UNIV

Skin taking device and using method thereof

The invention discloses a skin taking device and a using method thereof. The skin taking device comprises a shell, held by a hand, of the skin taking device. A dry battery for providing power for theskin taking device is arranged in the shell; a direct-current motor and a speed changer are arranged below the dry battery; a connecting shaft extends out of the bottoms of the direct-current motor and the speed changer and is inserted into a hollow rotating shaft. One or two connecting flat keys are arranged between the end surface of the hollow rotating shaft and the step surface of the connecting shaft. A skin taking knife is mounted at the front end of the hollow rotating shaft and includes a hollow knife rod and a trephine knife head connected to the front end of the knife rod; air guiding slots that are distributed in a radial pattern by using the hollow pipe orifice as the center are formed in the end surface of the trephine knife head. A cavity is formed between the connecting shaft end in the hollow rotating shaft and the cutter rod end and is communicated with an outside air guide pipe; the other end of the air guide pipe is connected with an air compressor; a change-over switch in a positive pressure state, a negative pressure state and a normal pressure state is connected to the air guide pipe. A button switch is installed at the top end of the skin taking device shell.

Owner:嘉兴市中医医院

New compound mode applied to compound molding skin

InactiveCN107471805AIncrease profitSave cutting processLaminationLamination apparatusCuticleBiochemical engineering

The invention discloses a new compound mode applied to compound molding skin. The new compound mode comprises a skin module which comprises eight to ten clamp clamping modules, a mould cavity module, a substrate skeleton module, a PP foam layer and a TPO layer, the substrate skeleton module comprises two to six first mould core modules and two to six second mould core modules, and the eight to ten clamp clamping modules are uniformly distributed on the periphery of the outer wall on one side of the skin module at equal intervals. In the new compound mode, the TPO layer meets the appearance surface of a product substrate, the PP foam layer meets the requirements of the molding process and the size of the technology edge, in the production of compound layers different in size, the fluctuation of the PP foam layer and the TPO layer in the skin production process is allowed, the waste problem that the skin is cut away in the skin production process is avoided, the material utilization rate is improved, and energy conservation and consumption reduction are achieved.

Owner:YANFENG HAINACHUAN AUTOMOTIVE TRIM SYST CO LTD

A continuous numerical control pipe bending machine

ActiveCN113617901BSolve the dead angle problemPrevent looseningMetal-working feeding devicesShaping safety devicesElectric machineryMachine

Owner:南通驰连机械有限公司

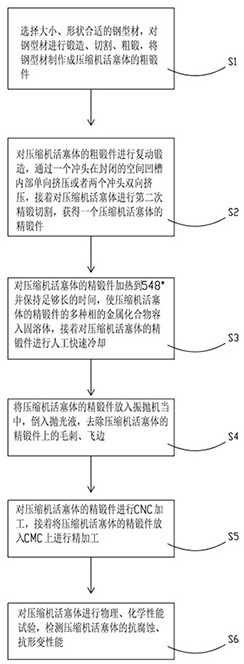

Precise forging process for novel compressor piston body of automobile

PendingCN114749597AGuaranteed mechanical propertiesGuaranteed CorrosionPistonsUltimate tensile strengthInternal stress

According to the precise forging process for the novel compressor piston body of the automobile, the rigidity and the strength of the compressor piston body are improved through the designed process aiming at the operation environment of the compressor piston body, the piston body is not prone to deformation during vertical operation, the piston body is heated through the high-temperature constant-temperature area, various metal phases of the piston body are fused into a solid solution, and therefore the piston body can be precisely forged. The internal stress of the piston body is eliminated, cracks occurring during operation of the piston body are avoided, the vibration polishing technology is adopted, finish paint is more firmly attached to the surface of the piston body, the rust resistance of the piston body is improved, double-action forging is adopted, the material utilization rate is increased, the forged piston body is free of flash, the process complexity is reduced, and the material cost is saved.

Owner:ALLOY SEIKO INDUSRIAL

Disposable vacuum sealing wound protecting material for fingers and instrument thereof

PendingCN109172148AImprove the quality of attractionRelieve painPharmaceutical delivery mechanismAdhesive dressingsPipetteSemipermeable membrane

The invention relates to a disposable vacuum sealing wound protecting material for fingers and an instrument thereof. The disposable vacuum sealing wound protecting material for fingers includes VSD auxiliary material sponge, biological semipermeable membrane, Drainage tube, hanging ring, Connector, pipette, pipette clamp, connection hole, connector 1, a suction bottle, connecting seat 2, one-wayintake valve, one-way outlet valve, hand-pinched balls, antibacterial layers, and an adhesive layer, wherein the connecting structure of the wound protection material from the inside to the outside isas follows: the adhesive layer -> the antibacterial layer -> the VSD auxiliary material sponge -> the biological semi-permeable membrane, a VSD auxiliary material sponge is internally connected witha drainage tube, a suction pipe is connected with the drainage pipe through a connector, a liquid pipette clamp is attached to that liquid pipette pipe, the connecting seat is arranged on the top endof the liquid pipette bottle on the right, a connecting hole is arranged on the connecting seat, the upper end of the connecting hole is connected with the liquid pipette pipe, the top end of the liquid pipette bottle on the right is connected with the connecting seat, the connecting seat is connected with a pinch ball by a one-way air inlet valve, and a one-way air outlet valve is arranged on thebottom end of the pinch ball by the left. The invention can reduce the workload of the doctor, shorten the operation time and provide the corresponding negative pressure.

Owner:SHANGHAI FIRST PEOPLES HOSPITAL

An integral ceramic pump body ceramic casting mold and its pressure ring structure

ActiveCN106827179BAvoid LeakageImprove sealingCeramic shaping apparatusCasting moldComposite material

An integral ceramic pump body ceramic casting mold and its pressure ring structure belong to the technical field of ceramic pump body processing tools, in particular to an integral ceramic pump body ceramic casting mold and its pressure ring structure. The invention provides an integral type which can avoid material leakage at the outer flange of the shell during the pouring process, and at the same time save the process of manually cutting the ceramic material after the ceramic material is solidified, thereby improving production efficiency and saving production supplies such as knives. A ceramic pump body ceramic casting mold and its pressure ring structure. The present invention is characterized in that: between the inner flange and the outer flange, a pressure ring which is matched with the outer surface of the mold is arranged; the pressure ring comprises a ring body, and the lower surface of the ring body is provided with a clamping groove corresponding to the annular protrusion; The inner flange of the mold body and the outer flange of the shell are connected by connecting bolts, the ring body is provided with through holes corresponding to the connecting bolts, and the inner flange is provided corresponding to the upper surface of the ring body. There are top wire holes.

Owner:SHENYANG FIRST PUMP CO LTD

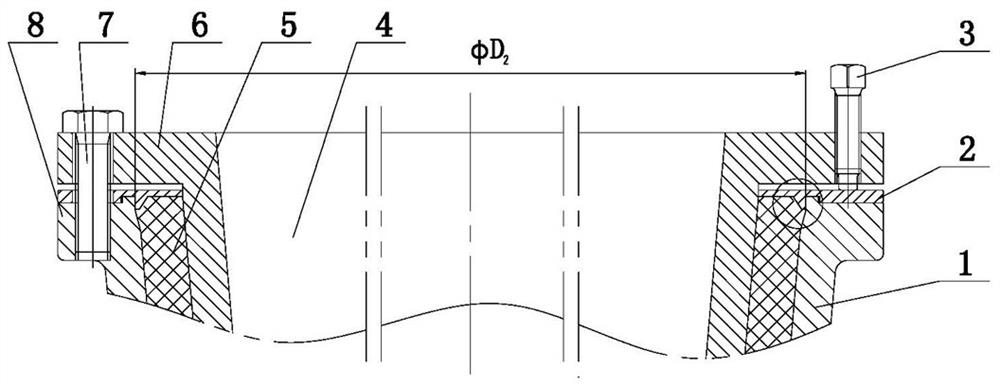

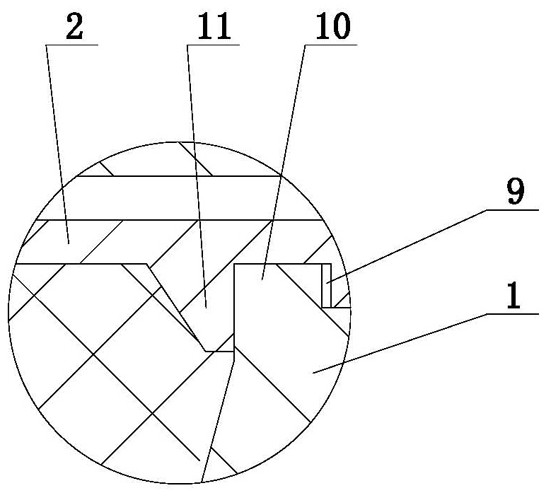

Method for the production of a stator and stator produced according thereto

InactiveCN1902801BReduced risk of looseningEasy to fixMagnetic circuit stationary partsManufacturing stator/rotor bodiesElectric machineEngineering

Disclosed is a method for the production of a stator core (20)for an electric machine, wherein a substantially rectangular packet of lamellae (40) is initially formed from strip-shaped lamellae (21); said packet is transformed and curved into an annular shape in one of the subsequent steps, having an axial direction (a) corresponding to the cylinder axis (z), said annular shape comprising axial front surfaces (46). The annular packet of lamellae (40) is at least partially plastically deformed at points on the axial front surfaces (46) in an axial direction (a) in one of the subsequent steps. A stator for an electric machine, particularly a generator for motor vehicles, is also provided. Said stator consists of a stator iron in the form of curved, strip-shaped lamellae (21), comprising axial front surfaces (46). The axial length of the inner diameter of the stator iron is greater than that of the outer diameter.

Owner:SEG AUTOMOTIVE GERMANY GMBH

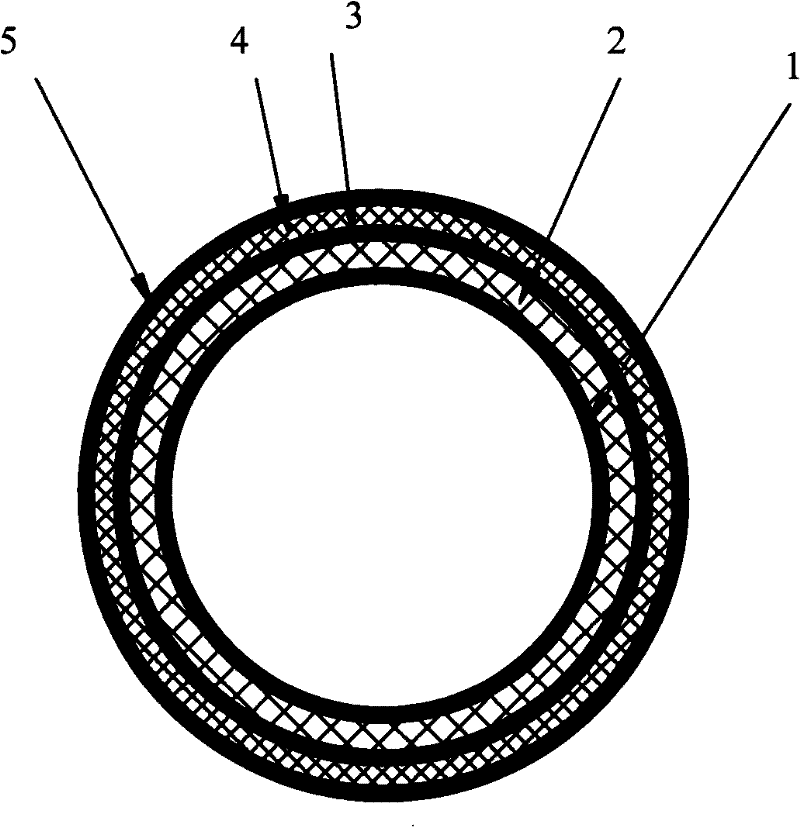

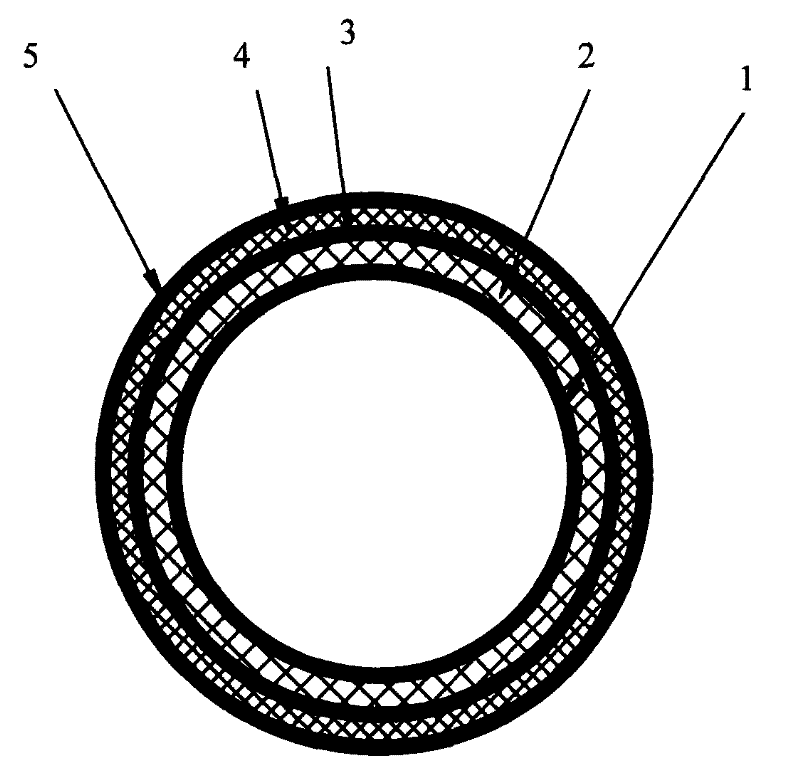

Wrapping-pulling woven high-strength composite material tube

The invention discloses a wrapping-pulling woven high-strength composite material tube which comprises a tubular knitting short-cut felt inner-felt wrapping layer, a straight-yarn pultrusion layer, a knitting short-cut felt middle-felt wrapping layer, a high-strength yarn weaving wrapping layer and a knitting short-cut felt outer-felt wrapping layer. The straight-yarn pultrusion layer is wrapped outside the knitting short-cut felt inner-felt wrapping layer, the knitting short-cut felt middle-felt wrapping layer is wrapped outside the straight-yarn pultrusion layer, the high-strength yarn weaving wrapping layer is wound outside the knitting short-cut felt middle-felt wrapping layer, and the knitting short-cut felt outer-felt wrapping layer is wrapped outside the high-strength yarn weaving wrapping layer. The invention has stronger comprehensive performance, high strength, large modulus, high performance resisting cutting and impact damage and good anti-fatigue performance, shock absorption performance and thermal stability performance and is widely suitable for various tent frames.

Owner:ARCHITECTURAL ENG INST GENERAL LOGISTICS DEPT P L A +1

A battery pole piece coating system and method

InactiveCN106910868BEfficient coatingReduce processElectrode collector coatingCoating systemAdhesive

Owner:SHENZHEN SHENG ENERGY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com