An integral ceramic pump body ceramic casting mold and its pressure ring structure

A kind of ceramic pump, integral technology, applied in the field of integral ceramic pump pump body ceramic casting mold and pressure ring structure, can solve the problems of insufficient ceramic lining ceramics, cleaning delays, delays in construction period, etc., to improve product quality and Effects of appearance, improvement of production efficiency, and improvement of airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

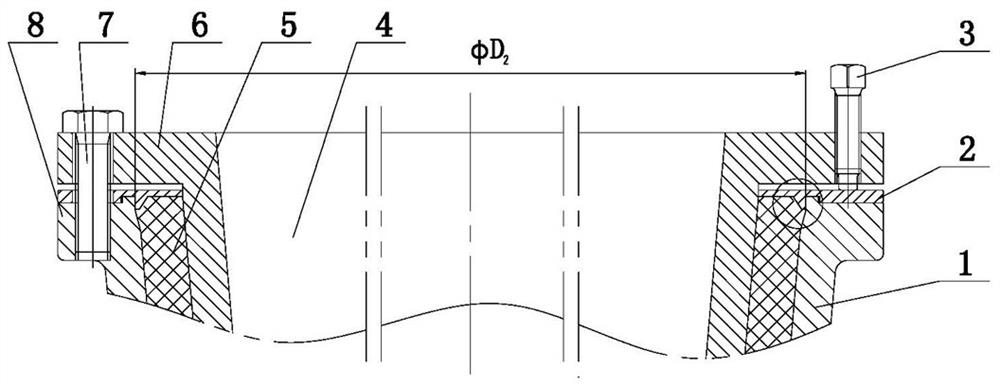

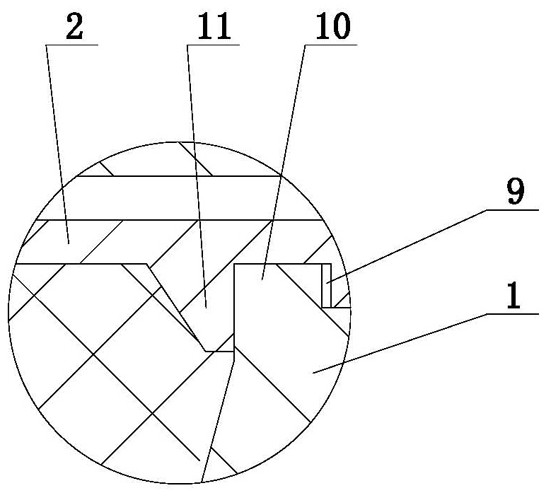

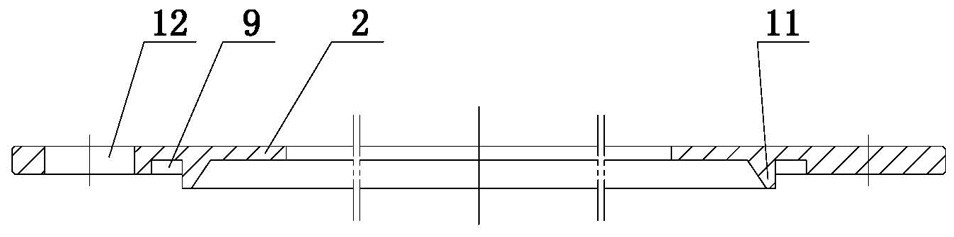

[0022] The present invention adopts the following technical solutions. The integral ceramic pump body ceramic casting mold of the present invention includes a mold body 4 and a shell 1. An inner flange 6 is provided at the water outlet of the mold body 4, and the shell 1 is provided with an inner flange 6. The outer flange 8 corresponding to the inner flange 6, the upper surface of the outer flange 8 of the housing 1 is provided with an annular projection 10, which is characterized in that: between the inner flange 6 and the outer flange 8, a mold is arranged between the inner flange 6 and the outer flange 8. Specifically 4 a pressure ring matched with an outer surface; the pressure ring includes a ring body 2, and the lower surface of the ring body 2 is provided with a clamping groove 9 corresponding to the annular protrusion 10; the inner flange 6 of the mold body 4 and the shell The outer flanges 8 of 1 are connected by connecting bolts 7, the ring body 2 is provided with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com