Variable thickness single fiber pull-out cement-based test piece mould and adjusting and testing method

A single-fiber, cement-based technology, applied in the preparation of test samples, manufacturing tools, ceramic molding machines, etc., can solve problems such as impact, achieve strong operability, avoid the risk of damage, and easy demoulding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

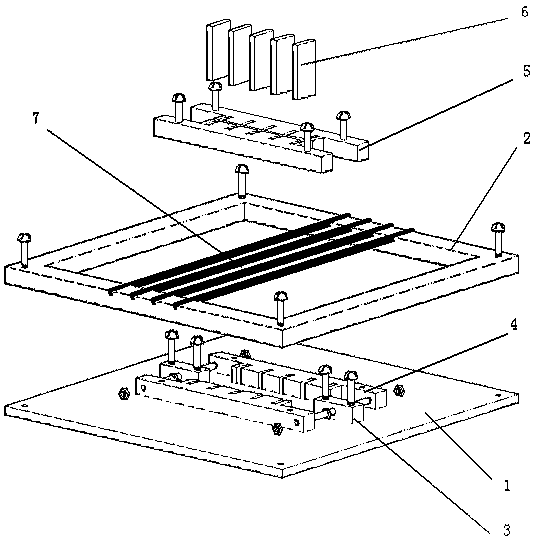

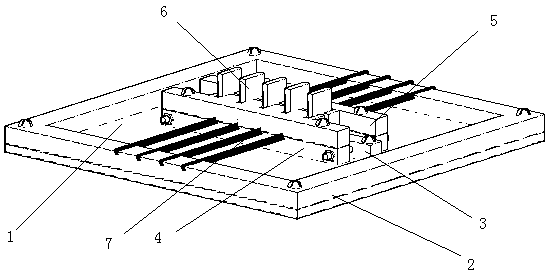

[0034] The invention provides a variable-thickness single-fiber-extracted cement-based test piece mold and an adjustment and testing method, which can obtain a single-fiber-extracted cement-based test piece with a specified thickness without loss of the test piece. The invention can pour multiple single-fiber pull-out cement-based test pieces at one time, has simple structure, strong operability, and easy demoulding, and there are partition plates between each test piece, which can be formed independently, and can be adjusted by adjusting The thickness of the poured specimen can be adjusted by adjusting the position of the flank module, thereby eliminating the cutting process in the traditional method and avoiding the risk of fiber / matrix interface damage caused by cutting.

[0035] attached figure 1 And attached figure 2 The states before an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com