Blood collection needle injection mold and blood collection needle injection technology

A technology for injection molds and blood collection needles, which is applied in the direction of coating, etc., can solve the problems of increased pain and insufficient penetration into the skin, and achieve the effect of small incision, beautiful appearance and saving injection molding process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

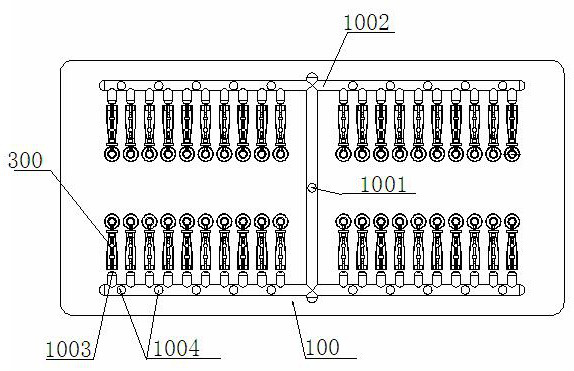

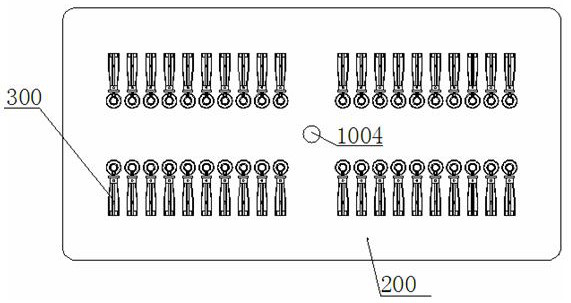

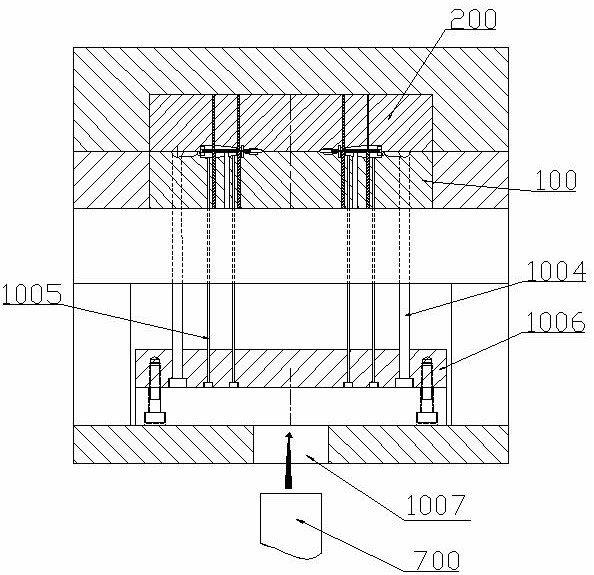

[0031] The present invention will be further described with reference to the accompanying drawings. The following examples are only used to illustrate the technical scheme of the present invention more clearly, but not to limit the scope of protection of the present invention.

[0032] In the description of the present invention, it should be understood that the terms center, longitudinal, transverse, upper, lower, front, rear, left, right, vertical, horizontal, top, bottom and inside

[0033] See attached Figure 1 The invention discloses an injection mold for a blood collection needle, which is formed by combining an upper mold 200 and a lower mold 100. The upper mold 200 and the lower mold 100 are provided with at least one corresponding mold cavity 300. In this embodiment, taking a plurality of mold cavities 300 as examples, each mold cavity 300 respectively includes a needle cap cavity 3001 and a needle handle cavity 3002 which are communicated with each other. The lower mold ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com