Pile-raft composite shock isolation trough foundation structure under strong shock

A foundation structure and pile-raft technology, which is applied in the field of pile-raft composite isolation trench foundation structures under strong earthquakes, can solve problems such as difficulty in meeting seismic isolation requirements and limited seismic isolation effect of rubber isolation bearings, and achieve attenuation or elimination of earthquakes. Outstanding energy, earthquake resistance, and disaster reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

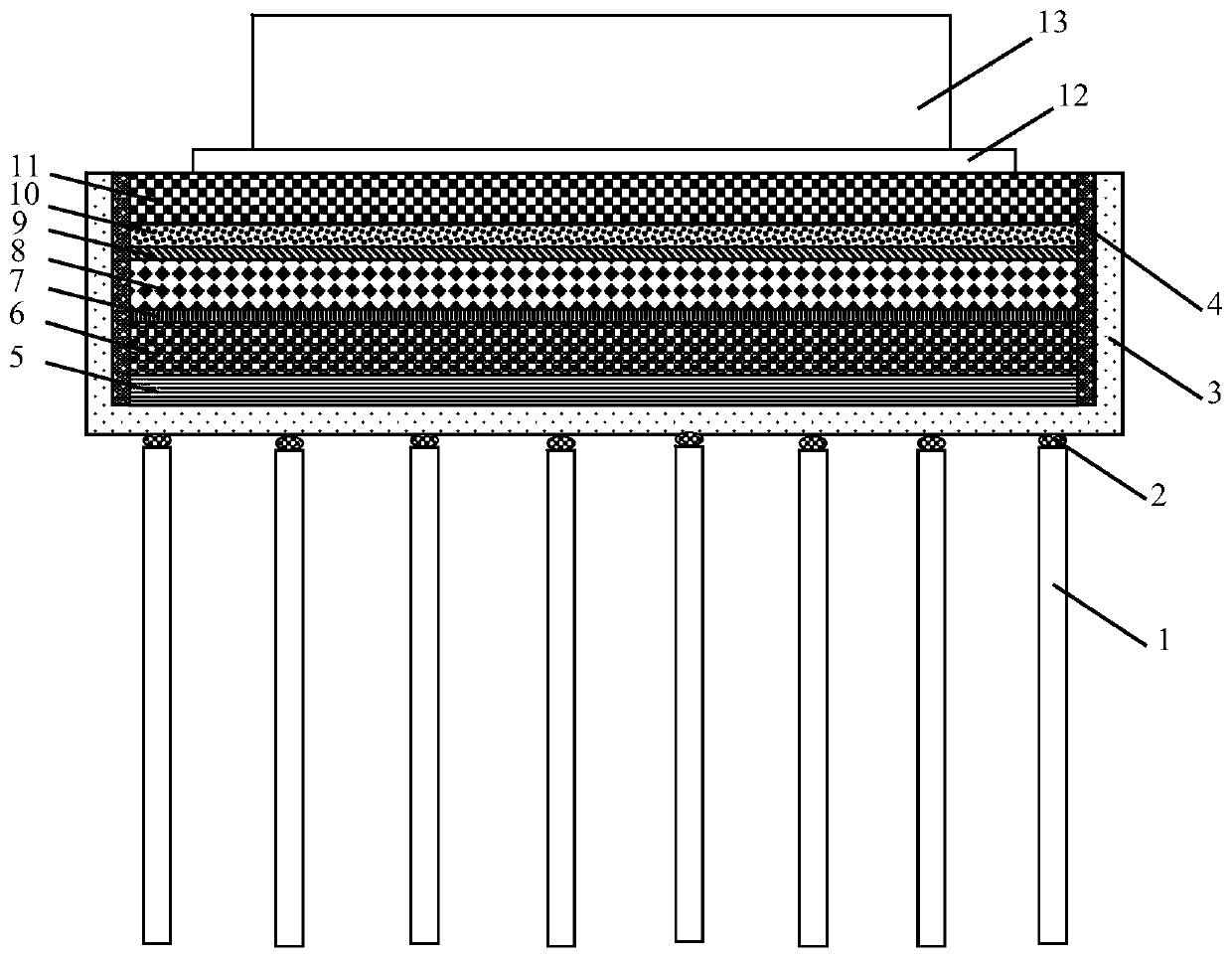

[0022] Such as figure 1 As shown, a pile-raft composite seismic isolation trench foundation structure under strong earthquakes, including multiple pile foundations 1 and multiple seismic isolation supports 2, multiple pile foundations 1 are laid in the foundation soil, and the pile top of each pile foundation is fixed A shock-isolation support 2 is installed, and also includes a shock-isolation groove 3. The shock-isolation groove 3 is installed on the vibration-isolation support, and a hot-melt rubber layer 4 is laid on the inner wall of the shock-isolation groove. From bottom to top, there are rubber cushion 5, pebble buffer cushion 6, geogrid 7, rubber gravel cushion 8, composite geomembrane 9, epoxy resin pouring layer 10, asphalt sand cushion 11 and raft 12 . During construction, the pile foundation 1 is first laid in the foundation soil, and the piles are arranged in a matrix; then, a rubber isolation support 2 is set on the top of the pile; then, a reinforced concrete ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com