Evaporation production process of polyester ultrathin film

A production process, ultra-thin film technology, applied in the field of polyester ultra-thin film evaporation production process, can solve the problems of low production efficiency, high production cost, low processing efficiency, etc., to improve production efficiency, reduce production cost, improve processing efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

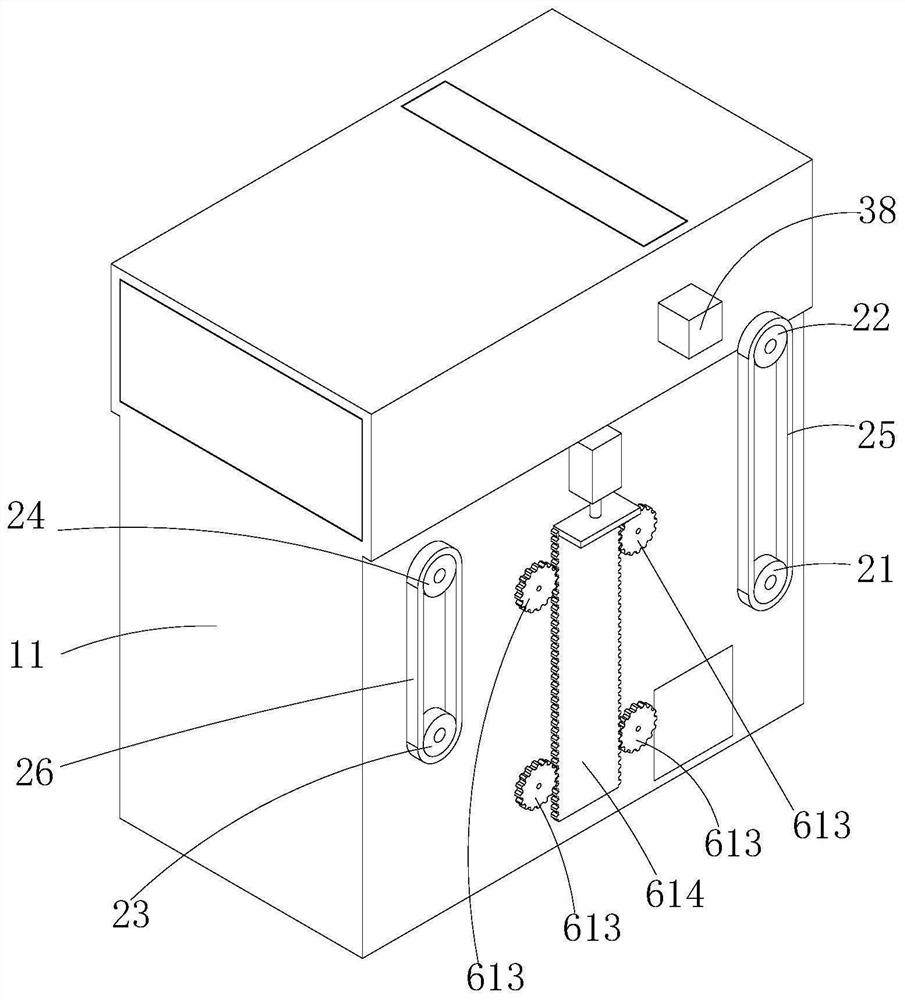

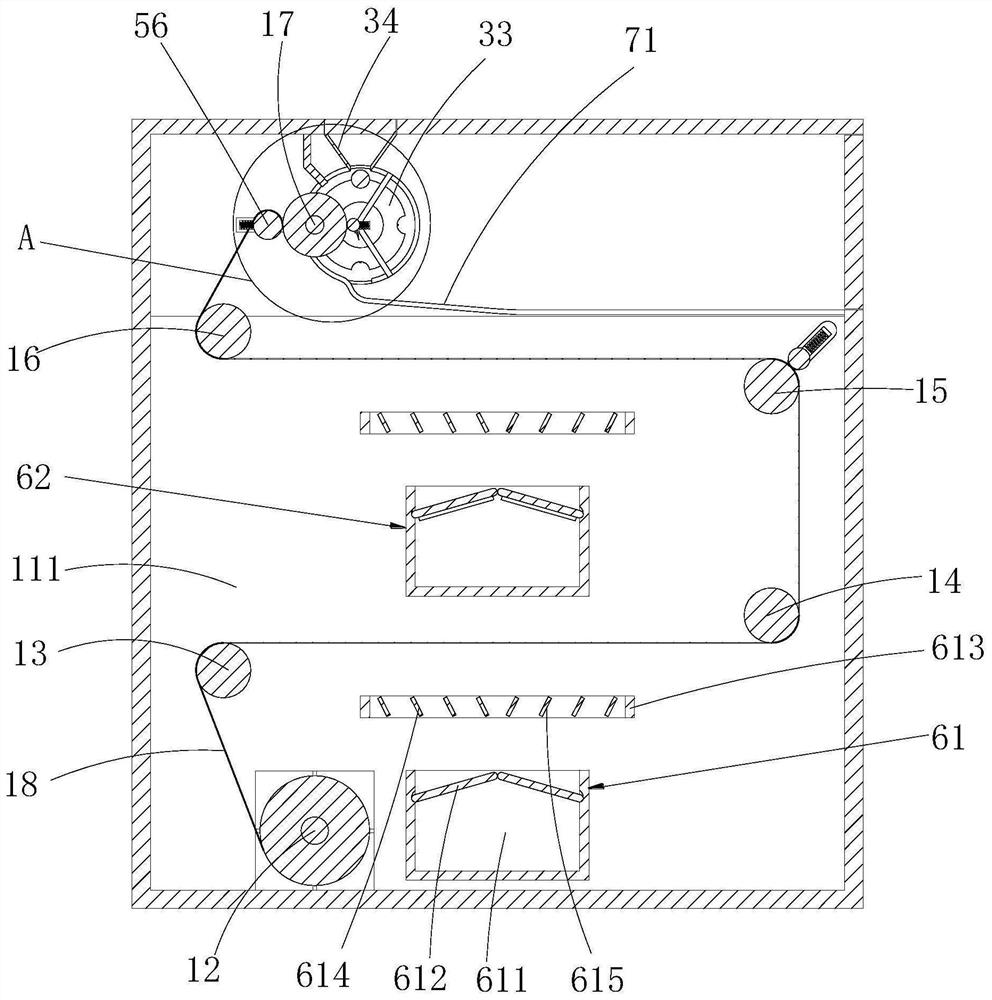

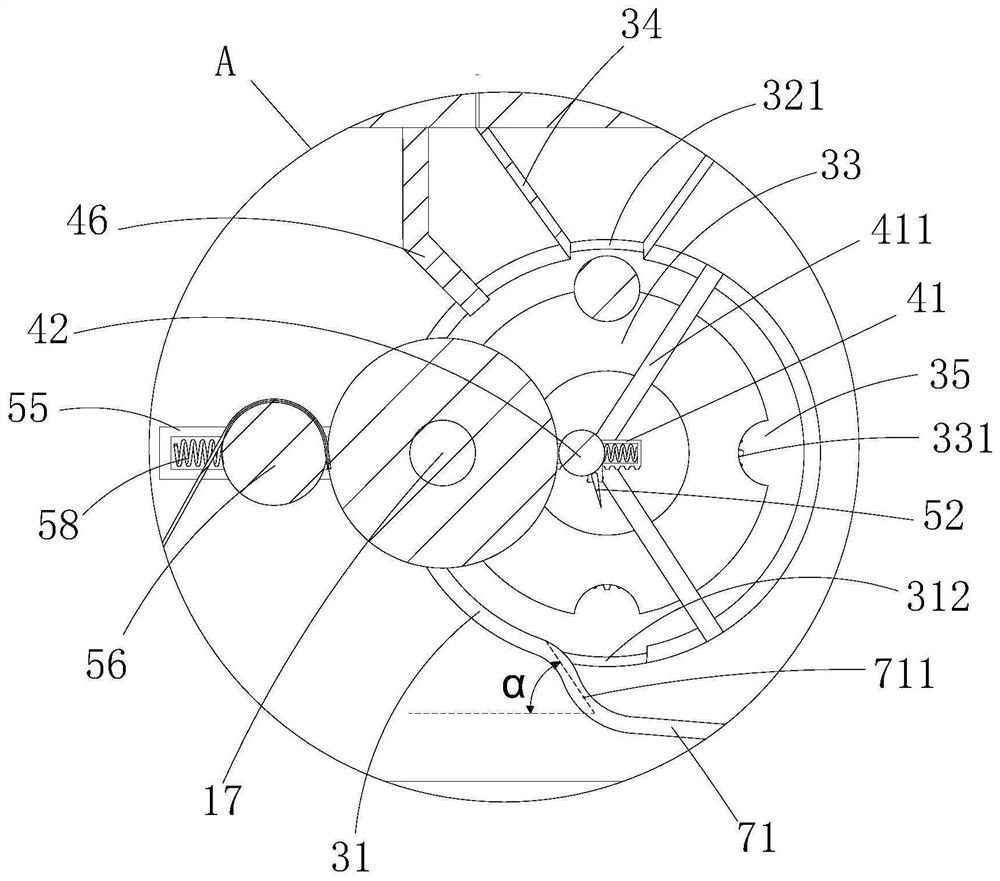

[0041] Such as Figure 1-16 Shown, a kind of vapor deposition production technique of polyester ultra-thin film, comprises the following steps:

[0042] S1: carry out the base film 18 piercing work;

[0043] The specific steps of S1 are as follows: sequentially install the film on the winding device along the film running route, and make the base film 18 pass through the first thermite evaporation area and the second thermite evaporation area in sequence; the winding device includes a chassis 11, Coating chamber 111, unwinding roll 12, first transition roll 13, first cooling roll 14, second transition roll 15, second cooling roll 16 and winding roll 17; described unwinding rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com