Solar cell module and package method thereof

A technology of solar cells and encapsulation methods, which is applied in the direction of electrical components, circuits, photovoltaic power generation, etc., can solve the problems of long coating time of butyl rubber strips, reduce the area of battery laying, and the design of butyl rubber strips is too narrow, etc., to achieve laying Increased range, flexible package size, and improved aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

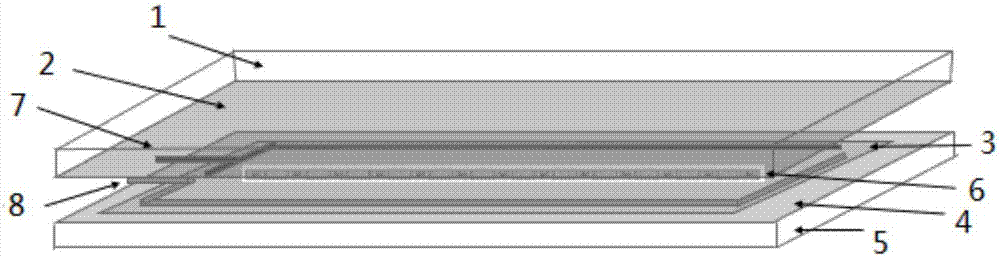

[0034] see figure 1 , the embodiment of the present invention provides a solar cell module packaging method, the packaging method includes the following steps:

[0035] S1, providing a substrate 5, a battery sheet group 3 and a front plate 1, the battery sheet group 3 including opposite first surfaces and second surfaces;

[0036] The material of the substrate 5 is glass, metal, semiconductor or organic plastic; the material of the front plate 1 is glass or transparent organic plastic. In this step, the substrate 5 and the front plate 1 need to be cleaned to avoid introducing impurities and affecting light transmittance.

[0037] In order to improve the ability of the edge of the finished module to resist water vapor or air erosion, in this embodiment, when arranging the battery pack 3 , a certain area is reserved at the edge, and the reserved area is filled with protective glue in subsequent steps. The width of the reserved area is related to the thickness of the battery sh...

Embodiment 2

[0052] This embodiment provides a method for packaging solar cell modules. The difference between this embodiment and Embodiment 1 is that in this embodiment, after the protective adhesive is arranged between the substrate 5 and the battery sheet group 3, in order to prevent the battery For the drift of the sheet group 3 , the present embodiment uses a mold or a fixture to limit the position of the battery sheet group 3 .

[0053] Likewise, this embodiment is not only applicable to the improvement of the encapsulation method of the first embodiment, but also applicable to the improvement of the encapsulation method of the second embodiment.

Embodiment 3

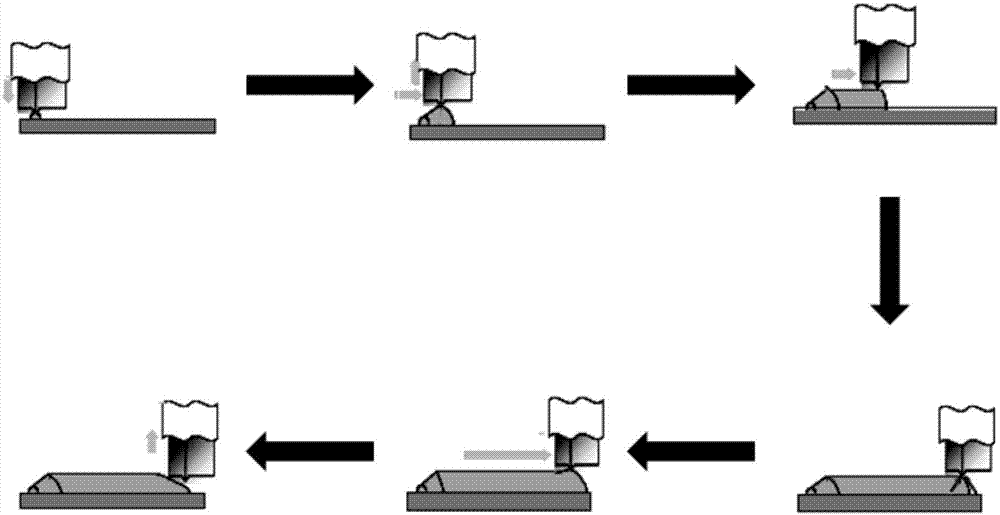

[0055] The difference between this embodiment and the above-mentioned embodiments is that in this embodiment, the stacked front plate 1, battery sheet group 3 and substrate 5 are fixed with a jig or a mold, and then the substrate 5 and the battery are sealed by potting. Sheet group 3, potting is performed between the front plate 1 and the cell sheet group 3; after the potting is completed, heating and lamination are carried out; similar to Example 1, in order to reduce packaging defects, it can be put into a sealed container and pumped. Vacuum treatment followed by heating and lamination.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com